Mechanical blast hole plugging device

A technology for machinery and blastholes, applied in the field of blasthole mechanical blocking devices, can solve the problems of labor cost, increased labor intensity, increased filling workload, and reduced blasthole utilization rate, etc., so as to improve blasthole utilization rate and reduce drilling Hole cost, effect of increased charge per hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

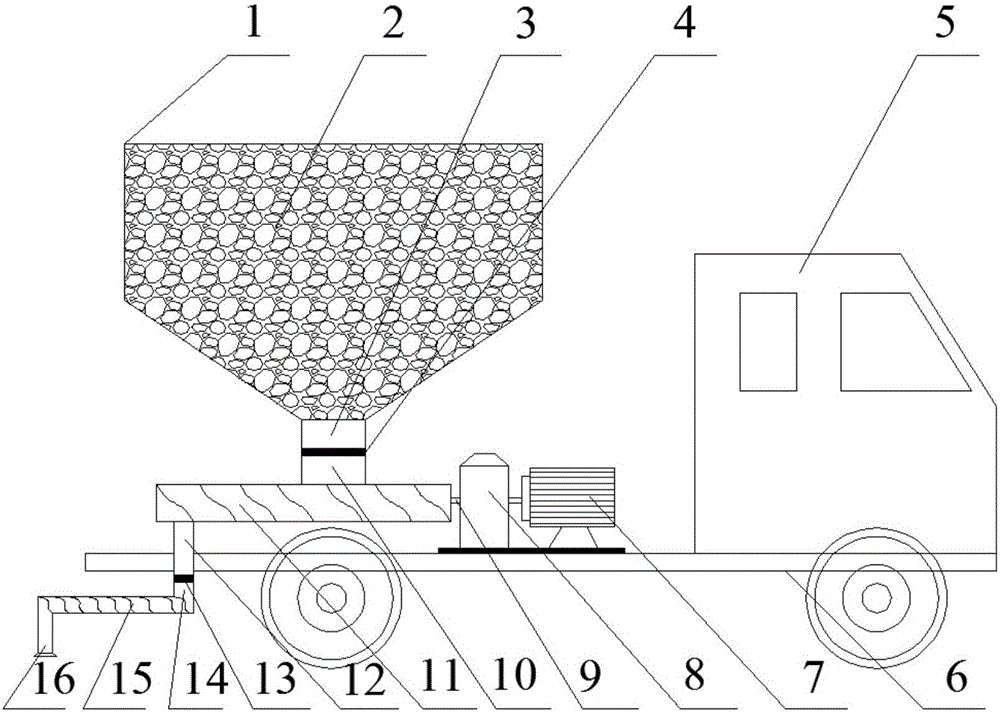

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0013] like figure 1 Shown, the present invention has motor vehicle chassis 6, and the front end of this motor vehicle chassis 6 is cab 5, and the specific structure of motor vehicle chassis 6 is identical with prior art, does not repeat them here. On the platform of the motor vehicle chassis 6, a graded batching bin 1 is arranged. The graded batching bin 1 is a funnel-shaped structure with a large top and a small bottom, and the upper end is open. The volume of the graded batching bin 1 is 2m 3 As mentioned above, the graded batching bin 1 is used to accommodate the graded batching 2, and the particle size of the graded batching 2 is 1 cm to 3 cm.

[0014] like figure 1 As shown, the discharge port 3 at the lower end of the grading bin 1 is connected to the feed port 10 of the first screw conveyor 11 through the flange 4, and the blade of the first screw c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com