Quasi-distributed temperature measurement optical cable built in smart cable

A quasi-distributed, intelligent cable technology, applied in the field of optical fiber sensing, can solve the problems of inaccurate measurement, large deviation between measurement points and heat source, and large interval between temperature measurement points, so as to increase the density of temperature measurement points and overcome strong gratings. The effect of limited number of single fiber multiplexing and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

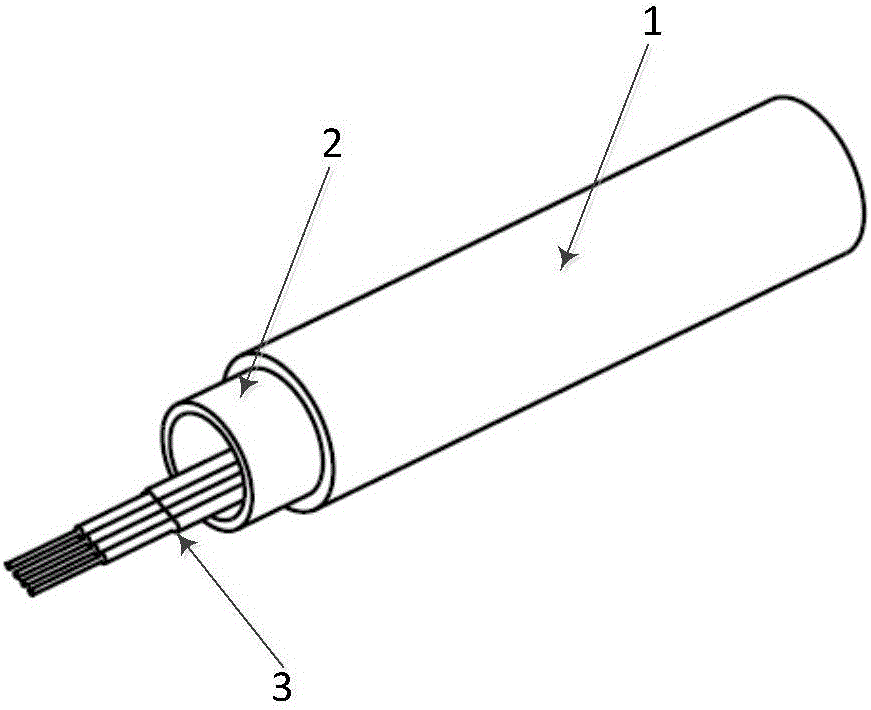

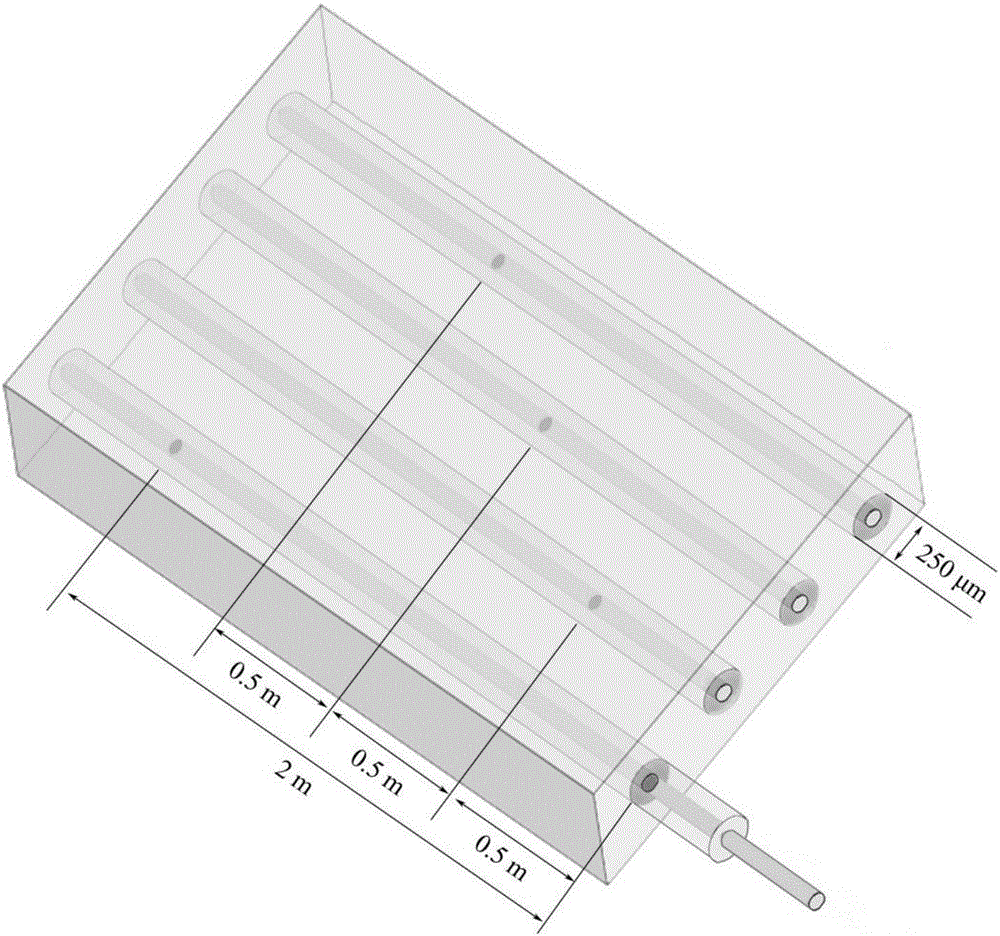

[0023] In view of the large distance between adjacent gratings in the large-capacity weak fiber grating sensing array, which may cause large temperature measurement errors due to the large distance between the temperature measurement point and the heating point on a single fiber, the present invention uses several sensing fibers to form a Instead of a single sensing fiber, the gratings on each sensing fiber are arranged at equal or unequal intervals, so as to increase the density of temperature measurement points and reduce the distance between the temperature measurement point and the conductor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com