Water tank type steam boilor

A technology of steam generator and water storage type, which is applied in steam generation, steam generation device, steam generation method, etc. It can solve the problems of heavy weight, reduced durability, high power consumption, etc., and achieve small and light products, temperature response Fast, low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

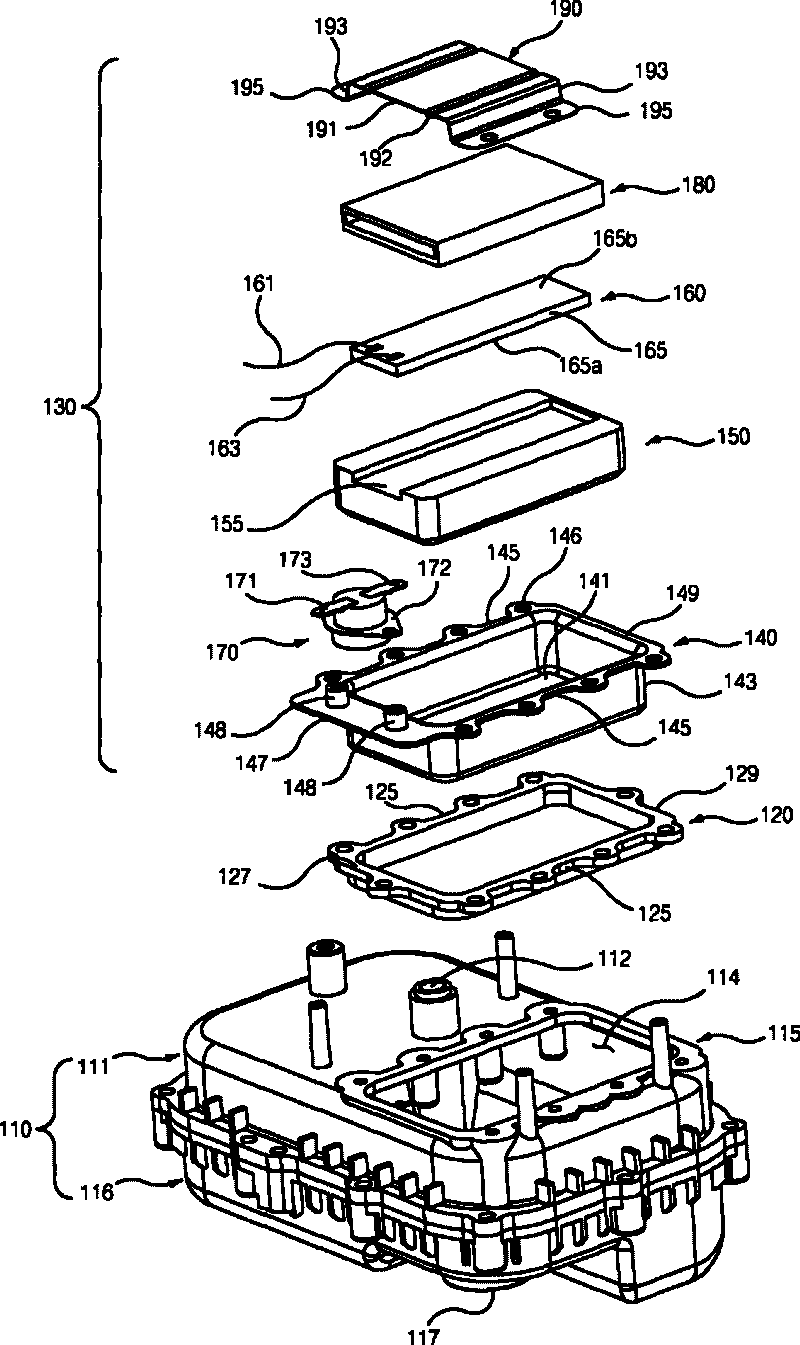

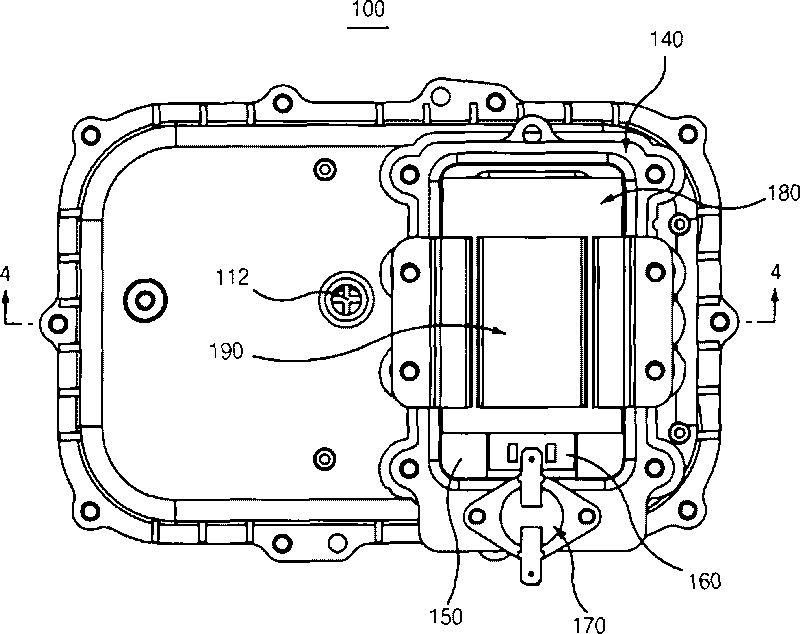

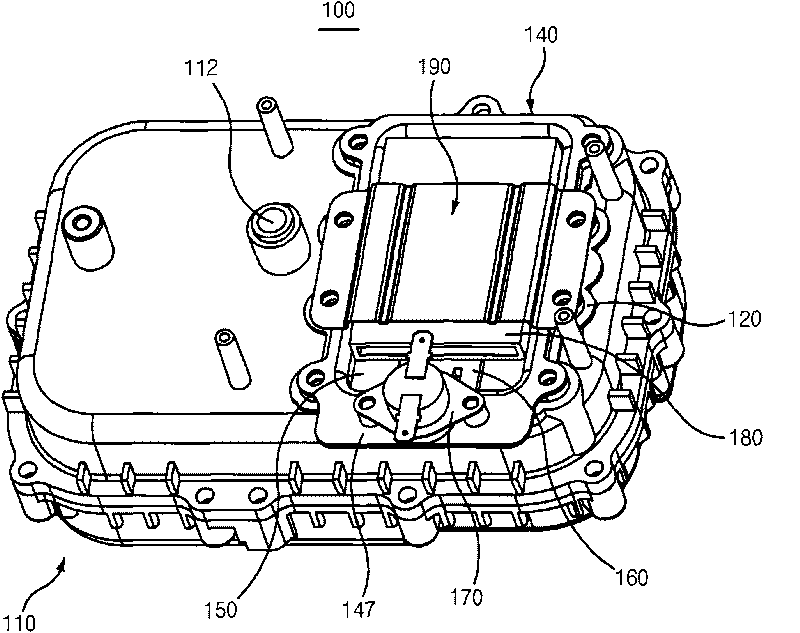

[0032] attached figure 1 It is a three-dimensional disassembled view of a storage-type steam generator according to an embodiment of the present invention, attached figure 2 to attach figure 1 Top view of the stored water steam generator in ; attached image 3 to attach figure 1 Perspective view of the stored water steam generator in ; attached Figure 4 to follow figure 2 Sectional view of line 4-4.

[0033] as attached figure 1 to attach Figure 4 As shown, in this embodiment, the storage-type steam generator 100 is composed of a water bucket 110 and a ceramic heating device 130 forming an appearance.

[0034] The water bucket 110 includes a heating body 111 and a heating cover 116 combined with the heating body 111. Connection holes and connection grooves are formed at the edges of the combination of the heating body 111 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com