Transformer temperature controller based on optical fiber temperature measurement

An optical fiber temperature measurement and transformer technology, which is applied to transformer/inductor components, thermometer applications, instruments, etc., can solve the problems of difficult maintenance of sealing system components, reduced measurement accuracy, and long thermal equilibrium time. The effect of high reliability, improved reliability and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

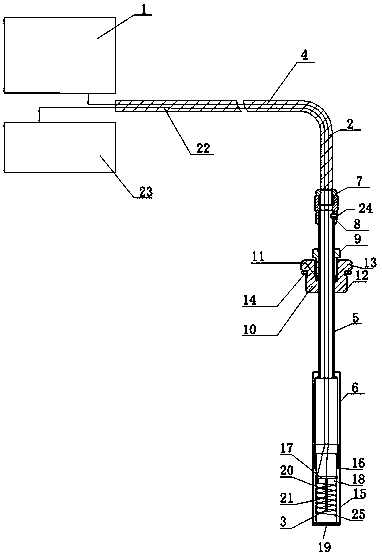

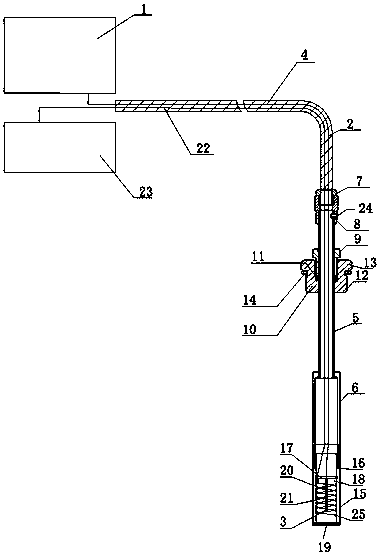

[0012] The transformer oil temperature controller based on optical fiber temperature measurement of the present invention, such as figure 1 Shown: Same as the prior art, there is an optical fiber temperature measuring host 1, the optical fiber temperature measuring host 1 is connected to the optical fiber temperature measuring probe 3 through the temperature measuring optical fiber 2, the difference from the prior art is that the optical fiber temperature measuring host 1 to The optical fiber 2 of the optical fiber temperature measuring probe 3 is sequentially covered with a metal hose 4, an extension tube 5 and an optical fiber protective cover 6. The metal hose 4 is a serpentine tube, and the extension tube 5 can be a stainless steel tube. The ends of the metal hose 4 are fixed. For some fixing parts 7, the end of the long pipe 5 is fixed with a joint 8 through a screw 24, and the fixing part 7 is threadedly connected with the joint 8. For secondary protection, the part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com