Method used for measuring frictional torque of hydrostatic bearing and other hydraulic devices

A static pressure bearing and friction torque technology, which is applied in the direction of measuring devices, bearing-related force sensors, mechanical bearing testing, etc., can solve the problems of non-quantitative judgment flexibility and friction measurement difficulties, and achieve accurate performance evaluation, Accurate measurement, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

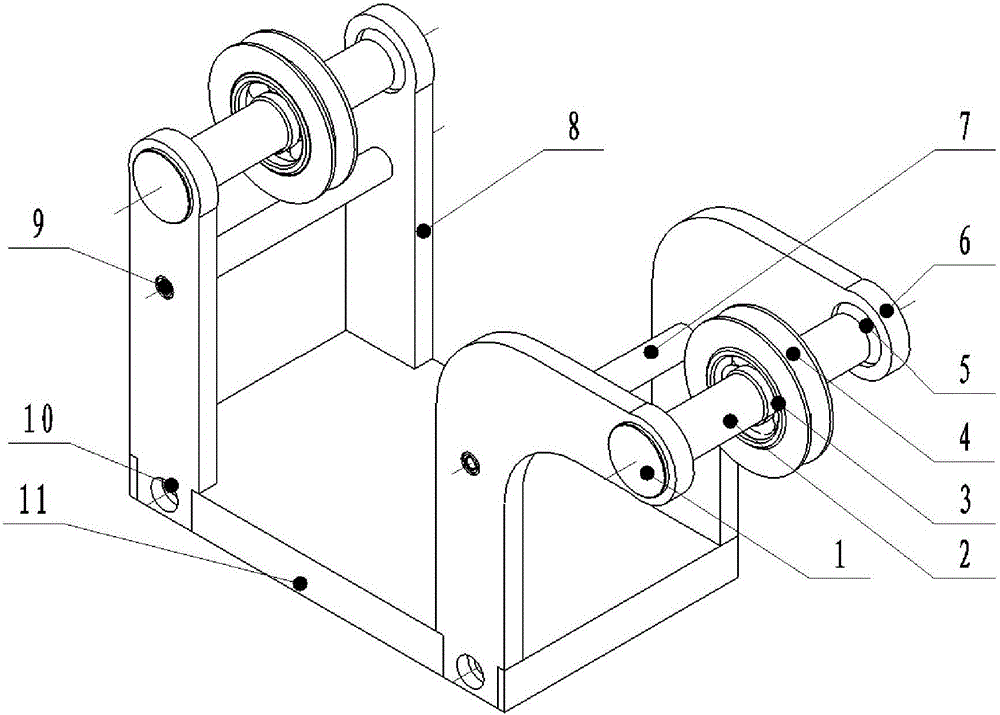

[0038] like figure 2 As shown, the measurement frame structural parts The measurement frame includes parts: a neodymium magnet 5 is located on the support arm 6, the vertical arm 8 is installed and fixed on the base 11 by the closing screw 10, the two ends of the front pull rod 7 are fixedly connected with the support arm 6, and the rear Both ends of the pull rod 9 are fixedly connected with the vertical arm 8 .

[0039] Including the following steps:

[0040] 1) The hydrostatic bearing 1 is placed on the test platform and leveled;

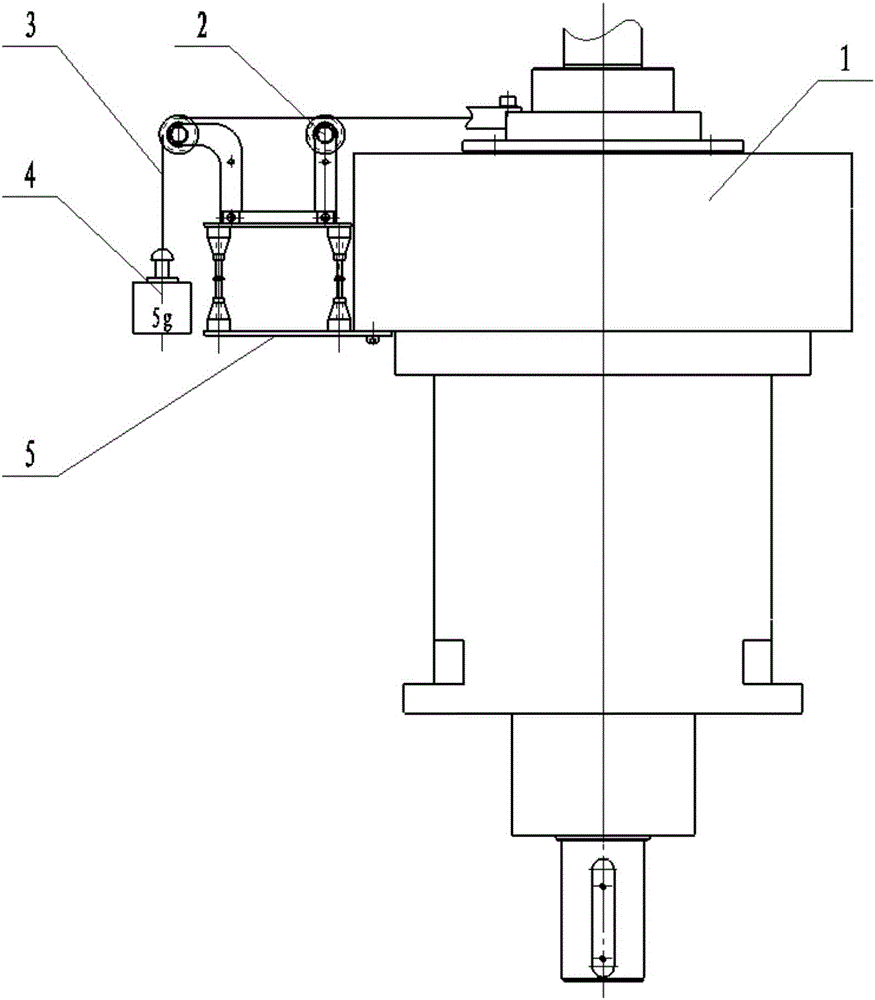

[0041] 2) if figure 1 As shown, the adjustment frame 5 is combined on the static pressure bearing 1, and the measuring frame 2 is placed on the adjustment frame 5;

[0042] 3) The tension line 3 is fixed on the force measuring arm of the hydrostatic bearing 1 and the length L of the force arm is measured, unit: mm;

[0043] 4) To adjust the height and level of the adjustment frame, it is required that the two pulleys of the measuring frame 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com