Elimination method of dead zone defect between primary equipment and secondary equipment in smart substation

A technology of smart substation and primary equipment, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of incomplete inspection of the dead zone of primary equipment and secondary equipment, failure of intelligent substation operation, misoperation, etc., to avoid Potential safety hazards and defects, improving the effect of strong intelligence and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

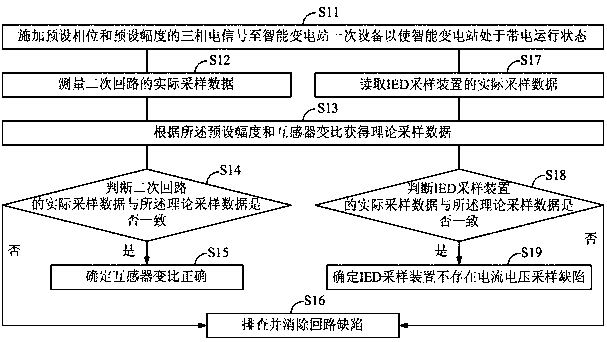

[0022] figure 1 It is a schematic flowchart of a method for eliminating dead zone defects between primary equipment and secondary equipment in a smart substation in this embodiment. The method for eliminating dead zone defects between primary equipment and secondary equipment in a smart substation includes:

[0023] Step S11, applying a three-phase electrical signal with a preset phase and a preset amplitude to the primary equipment of the smart substation so that the smart substation is in a live running state. Before implementing this elimination method, the smart substation has completed various professional tests such as high voltage, metering, and chemical rings, and the secondary commissioning has been completed, and the smart substation is in a state of preparation before being put into operation.

[0024] The dead zone defects between primary equipment and secondary equipment in smart substation include current defects and voltage defects. When eliminating current def...

Embodiment 2

[0030] continue to refer figure 1 , the difference between this embodiment and embodiment 1 is that it also includes:

[0031]Step S17, reading the actual sampling data of the IED sampling device. Specifically, the IED sampling device includes a protection device, a measurement and control device, a network analysis tester, a fault recording device, a watt-hour meter, and an electric energy collection device. The smart substation is divided into primary equipment and secondary equipment. Through the voltage transformer and current transformer installed on the primary equipment, the high voltage and high current on the primary equipment can be converted by a certain transformation ratio to obtain the secondary sampling value for the secondary Device sampling monitoring to protect primary device status. When eliminating current defects, read the actual current sampling data on protection devices, measurement and control devices, network analysis testers, fault recording device...

Embodiment 3

[0035] Compared with Embodiment 2, this embodiment also includes: judging whether the polarity of the current transformer and the current phase relationship are correct according to the three-phase current waveform on the network analysis tester and the fault recorder, and according to the network analysis tester and the fault The three-phase voltage waveform on the wave recording device judges whether the voltage phase relationship is correct. If the phase relationship between the three-phase electrical signal waveforms on the network analysis tester and the fault recorder is consistent with the applied three-phase electrical signal of preset phase and preset amplitude, it means that the current phase relationship / voltage phase relationship is correct And the polarity of the current transformer is correct, otherwise it is necessary to rule out and eliminate the loop defect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com