Combiner box automatic pairing testing system and testing tool thereof

An automatic pairing and testing system technology, which is applied in the monitoring of photovoltaic systems, measuring devices, measuring electricity, etc., can solve the problems of cumbersome unwiring operations and low efficiency, and achieve the effect of convenient operation and improved testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

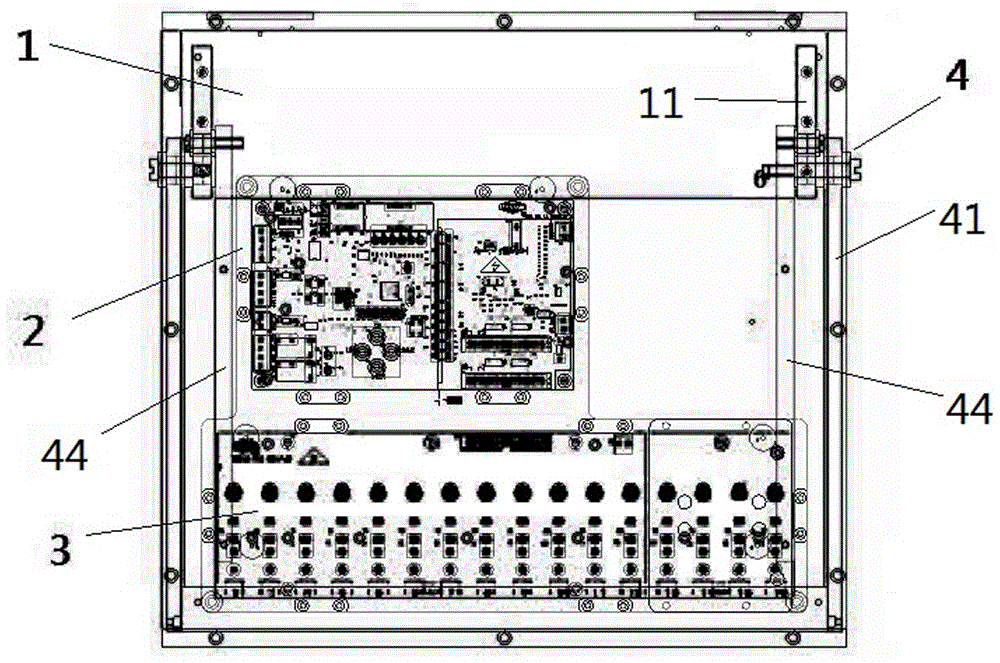

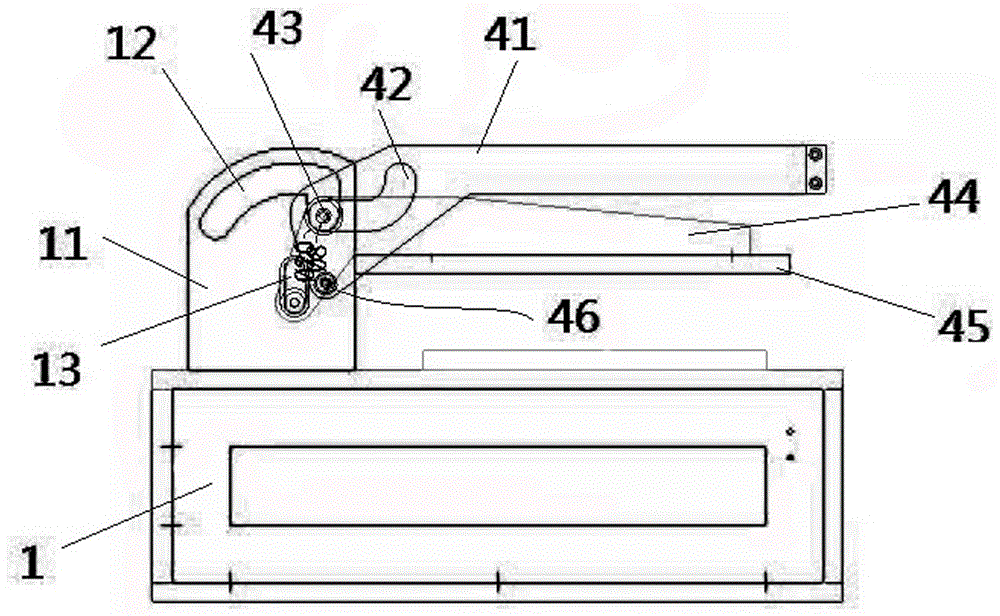

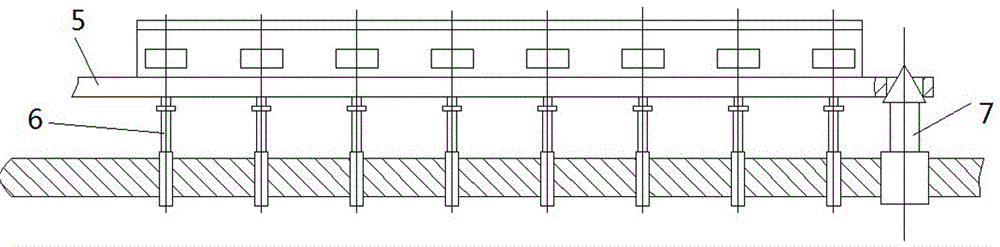

[0021] The embodiment of the automatic pairing test system of the combiner box of the present invention includes a DC voltage test part, a DC voltage test part, and a test tool for fixedly installing the tested part. The DC voltage test part includes a standard DC current source, and the DC voltage test part includes a standard DC voltage source. The DUT consists of a measurement board and a manifold. Such as Figure 1-3 As shown, the test tooling includes a base on which a set of spring test pins 6 are provided for conductive insertion of corresponding terminals of the DUT during testing. The spring test pins include input spring test pins and output spring test pins. , to connect the corresponding input voltage source and current source, eliminating the need for wiring operations for each test.

[0022] The base 1 is provided with a placement plate 5 for placing the tested piece, the lower end of each spring test pin 6 is fixed on the base, the upper end of the spring test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com