Hydraulic radial steel gate constrained damping layer vibration reduction design method

A curved steel gate and constrained damping technology, which is applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as load effect exceeding material strength, large arm vibration, damage, etc., to reduce flow induced load effect, the effect of improved calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

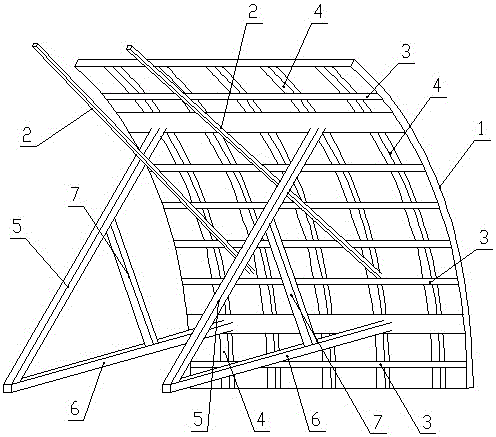

[0031] Such as Figure 1-3 As shown, the arc-shaped steel gate includes an arc-shaped panel 1, two suspenders 2 and two arms. The rear surface of the arc-shaped panel 1 is evenly spaced along its height direction with a number of beams 3, and each beam 3 is horizontally aligned along the left and right sides. direction setting, the rear surface of the curved panel 1 is evenly spaced along its width direction with several longitudinal beams 4, each longitudinal beam 4 is in an arc-shaped structure and has the same radian as the curved panel 1, and the two suspenders 2 are arranged obliquely and Parallel to each other, one end of the two suspenders 2 is respectively connected to the rear surface of the curved panel 1, each support arm includes an upper cantilever 5 and a lower cantilever 6, and a web 7 is arranged between the upper cantilever 5 and the lower cantilever 6; A curved steel gate such as figure 1 As shown, the width and height of the curved steel gate are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com