Magnetic adsorption mechanism and magnetic building block applying same

A technology of magnetic adsorption and magnetic building blocks, applied in the direction of magnetic objects, magnets, electrical components, etc., can solve problems such as cost rise, environmental damage, and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

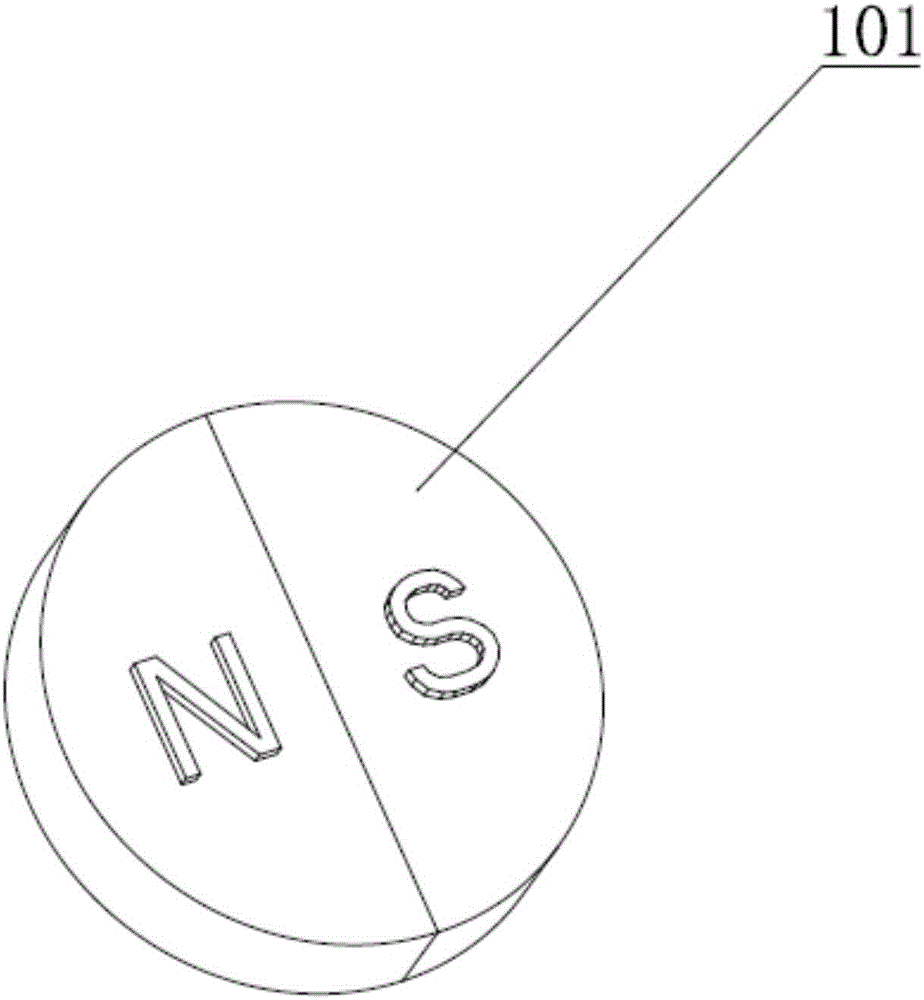

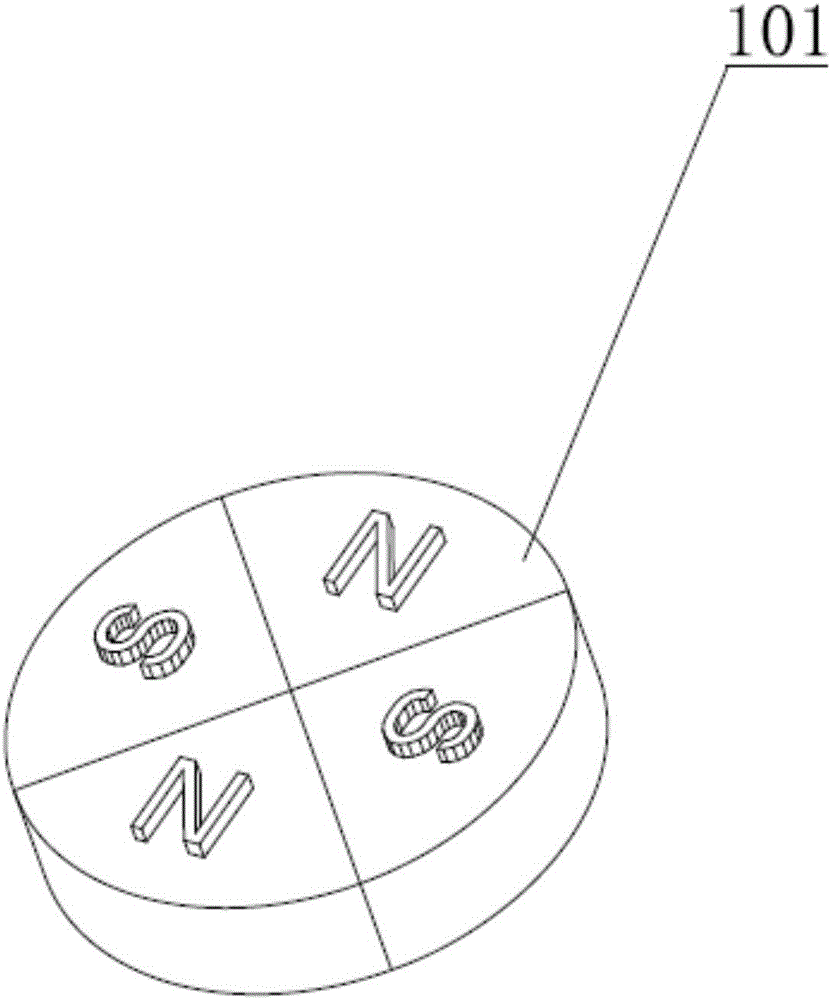

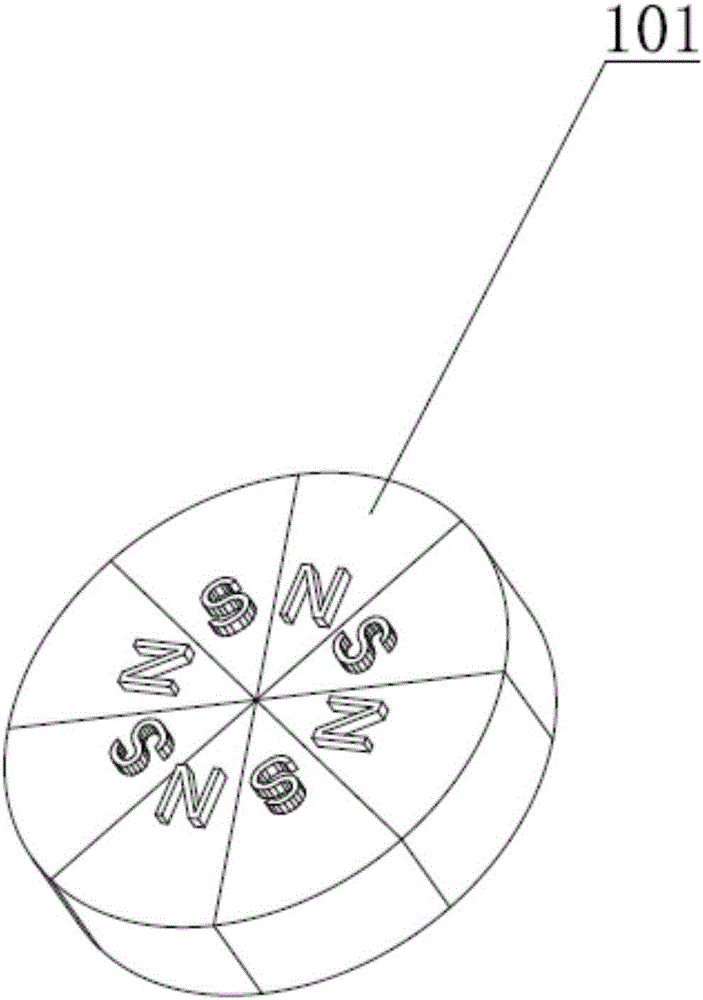

[0063] Such as figure 1 As shown, the adsorption surface of the magnet 101 includes an S pole and an N pole, and each of the S pole and the N pole accounts for half of the adsorption surface. Such as figure 2 As shown, the adsorption surface of the magnet 101 includes two S poles and two N poles, each S pole occupies a quarter of the adsorption surface, and each N pole also occupies a quarter of the adsorption surface. Such as image 3 As shown, the adsorption surface of the magnet 101 includes four S poles and four N poles, each S pole accounts for one-eighth of the adsorption surface, and each N pole also accounts for one-eighth of the adsorption surface.

[0064] Such as Figure 4 , 5 , 8, a magnetic adsorption member includes a magnetic component 10 and a support component 20 supporting the magnetic component 10, the magnetic component 10 includes a magnet 101, the magnet 101 includes an adsorption surface 1011, and the adsorption surface 1011 Including one S pole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com