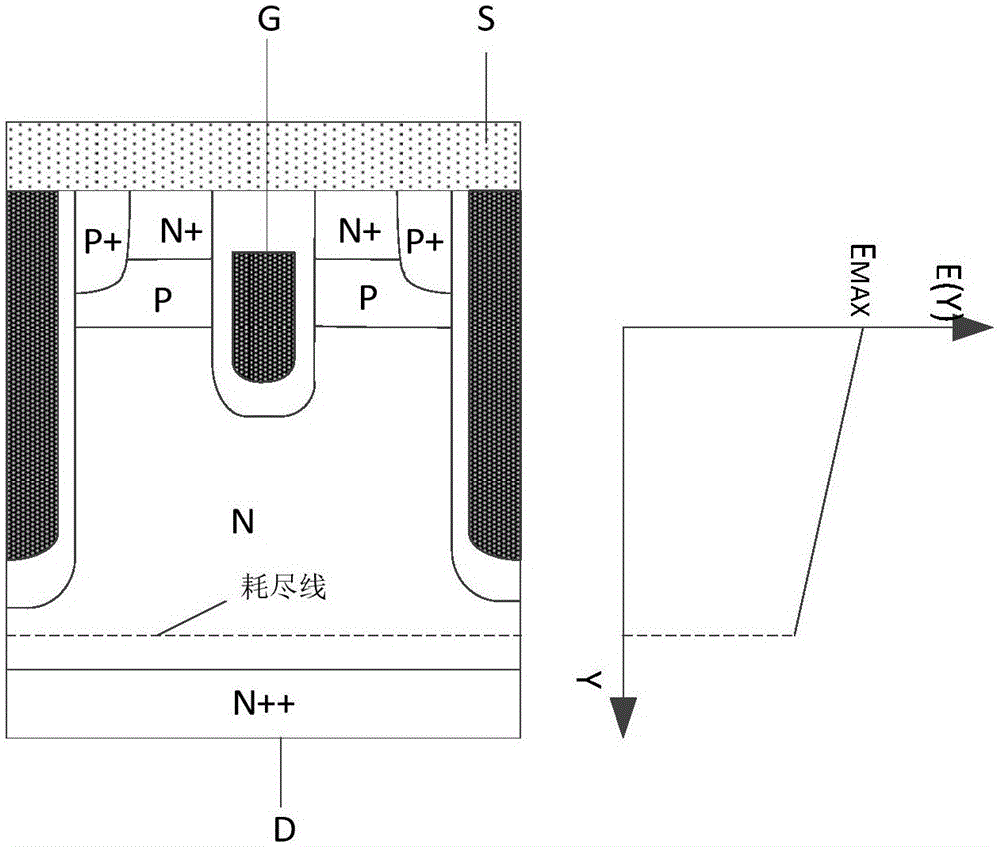

VDMOS of groove structure

A technology of grooves and inner grooves, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as restricting reverse withstand voltage, high source-drain capacitance Cds, and affecting device dynamic characteristics, so as to improve reverse blocking The effect of low voltage, gate-to-drain capacitance Cds, and uniform distribution of lateral electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

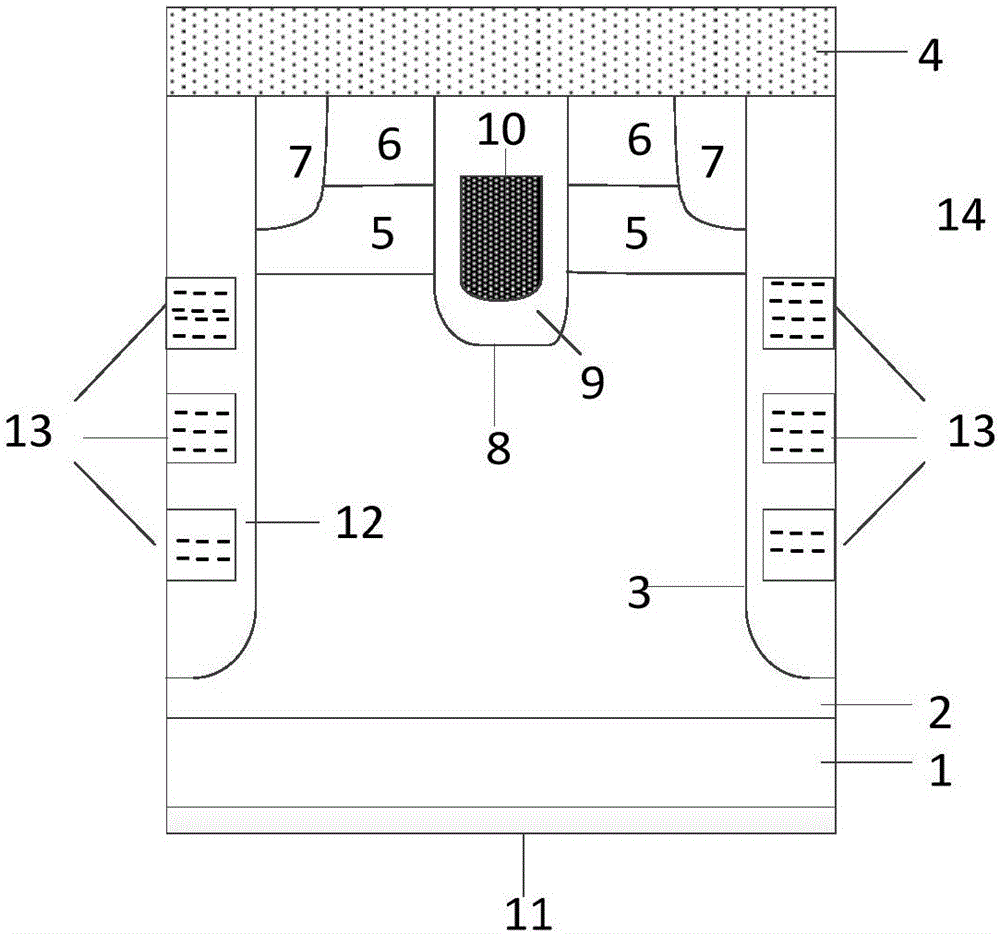

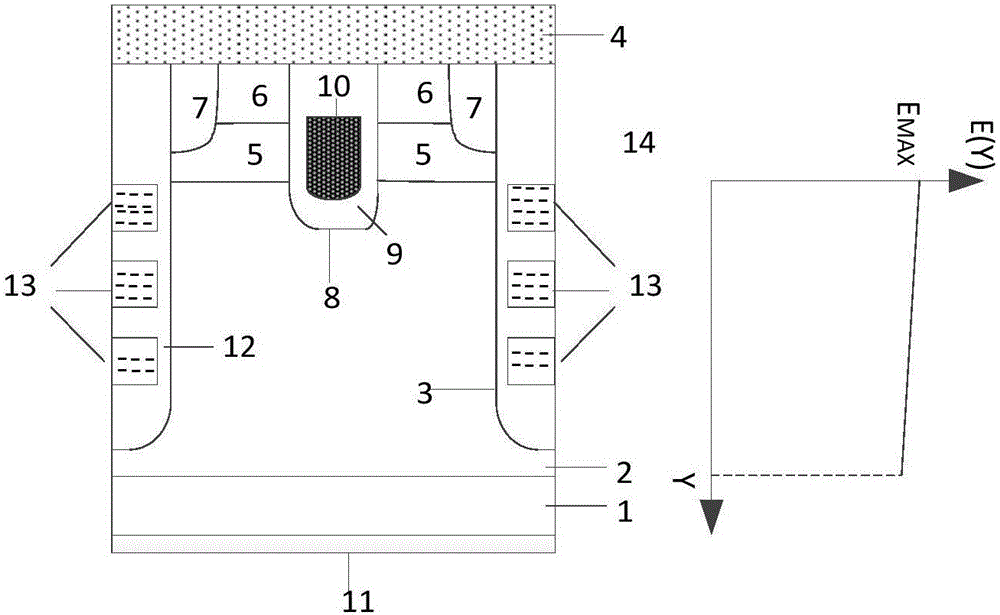

[0016] like image 3 As shown, a VDMOS with a trench structure in this example includes a metallized drain 11, an N+ substrate 1, an N-drift region 2, and a metallized source 4 that are sequentially stacked from bottom to top; Region 2 has internal trenches 3, P-type doped regions 5, N-type heavily doped regions 6, P-type heavily doped regions 7, and trenches 8, and the P-type doped regions 5 are located in the internal trenches on both sides. Between the grooves 3, and the side of the P-type doped region 5 is in contact with the side of the groove 3 in the body; the N-type heavily doped region 6 is located on the upper surface of the P-type doped region 5, and the N-type heavily doped region 6 The upper surface is in contact with the lower surface of the metallized source electrode 4; the P-type heavily doped region 7 is located between the internal trench 3 and the N-type heavily doped region 6 and is located between the internal trench 3 and the N-type heavily doped region ...

Embodiment 2

[0036] The structure of this example is based on Example 1. All N-type materials in Example 1 are replaced with P-type materials, all P-type materials are replaced with N-type materials, and negative charges in the polysilicon 13 are replaced with positive charges.

[0037] When making devices, semiconductor materials such as silicon carbide, gallium arsenide, or silicon germanium can also be used instead of silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com