AC-DC-AC auxiliary converter of motor train unit and working process of AC-DC-AC auxiliary converter

A technology for assisting converters and working processes, applied in the field of converters, can solve problems such as unfavorable maintenance, complicated control methods, single power supply system, etc., and achieve suppression of excessive input current impact, easy elimination, and low harmonic content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

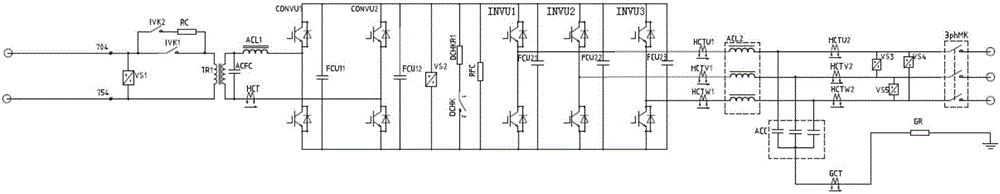

[0026] see figure 1 , the invention discloses an AC-DC-AC type EMU auxiliary converter, the auxiliary converter includes a controller, a pre-charging circuit, a step-up transformer, an input filter circuit, a rectifying circuit, a discharging circuit, an inverter module, Output filter circuit and output contactor.

[0027] The pre-charging circuit ensures that the DC bus voltage rises slowly, which can effectively suppress the excessive input current impact during uncontrollable rectification. The pre-charging circuit includes a pre-charging resistor RC, a pre-charging contactor IVK2 and a main contactor IVK1. The pre-charging resistor RC is connected in series with the pre-charging contactor IVK2, and the main contactor IVK1 is connected in parallel with the pre-charging resistor RC connected in series with the pre-charging contactor IVK2.

[0028]When the auxiliary converter starts, the pre-charging contactor IVK2 is closed, and the intermediate voltage supporting capacito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com