Liquid cooling cold plate and manufacturing method thereof

A technology of liquid-cooled cold plate and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, electrical equipment structural parts, electrical components, etc., and can solve problems such as high heat flux density, influence on the operation of electronic equipment, and overheating damage to electronic equipment. Achieve high heat dissipation efficiency, improve heat dissipation efficiency, and increase heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

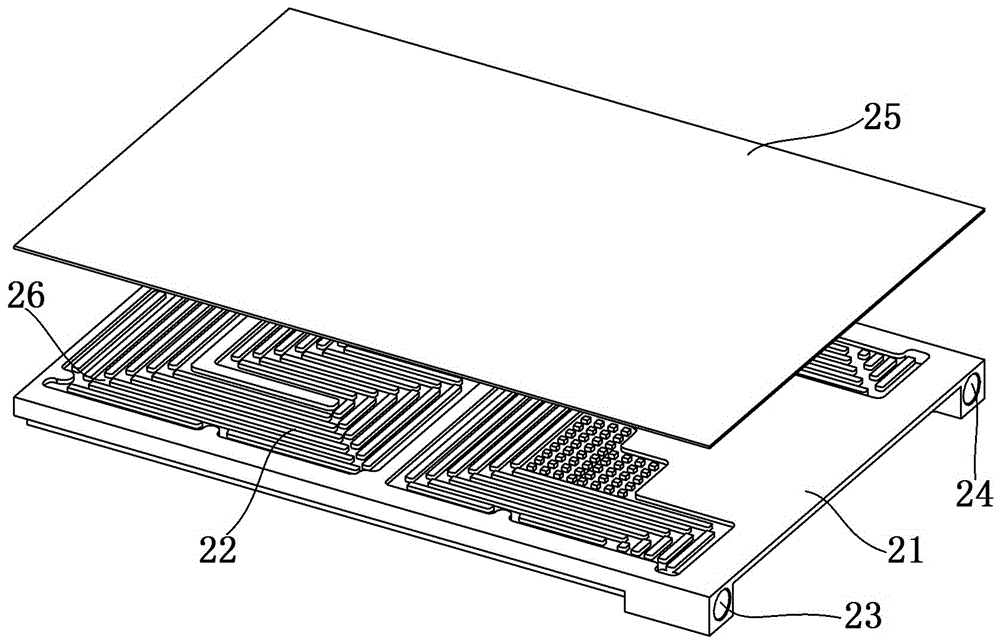

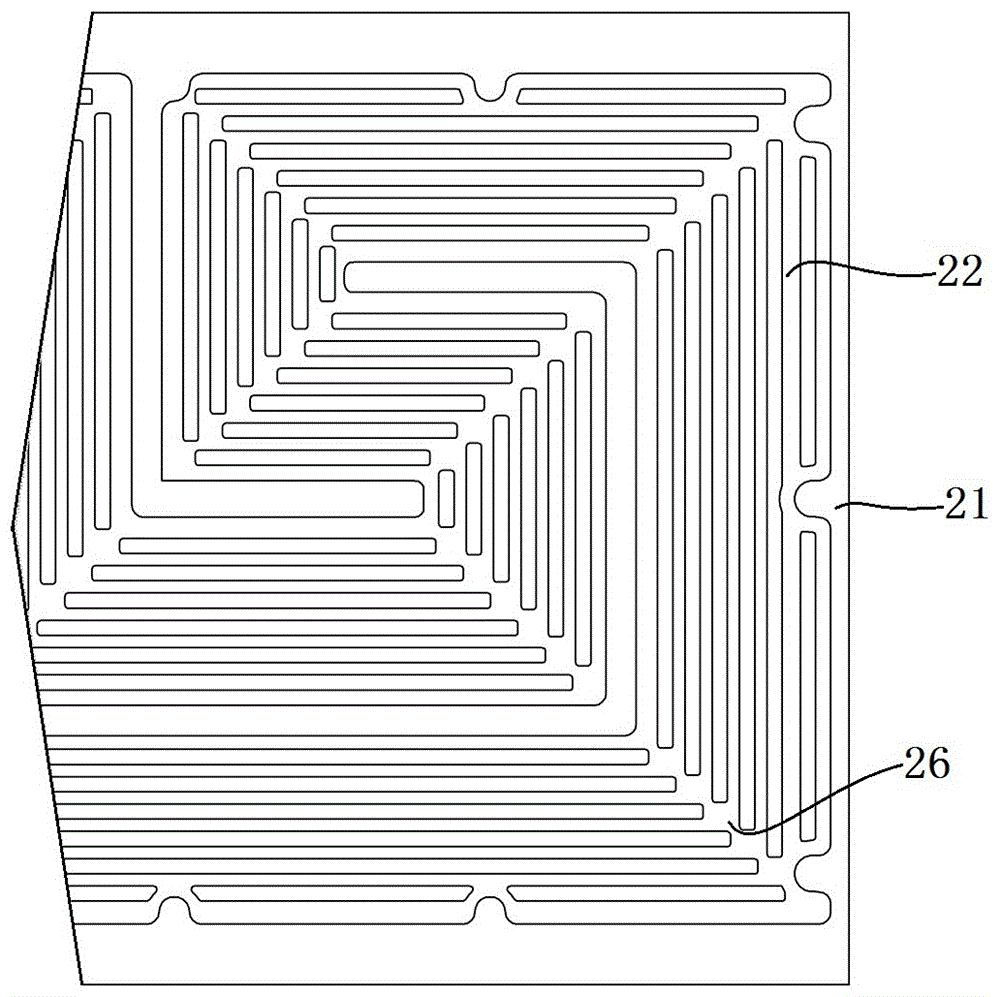

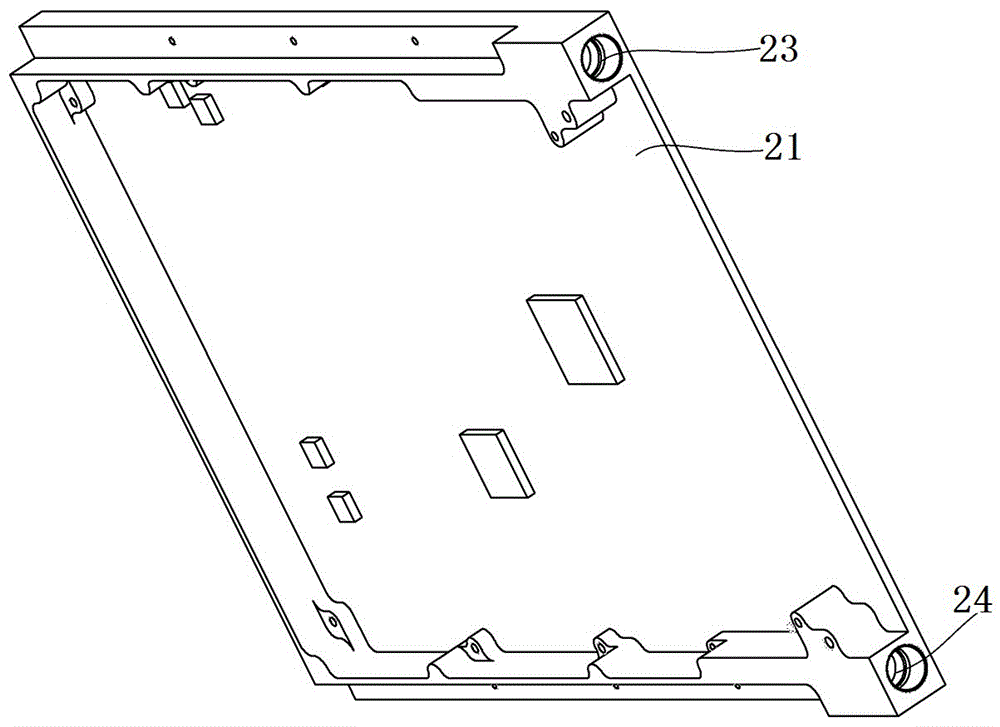

[0016] A specific embodiment of the liquid-cooled cold plate of the present invention, such as Figure 1 to Figure 3 As shown, the liquid-cooled cold plate includes a base plate 21 and a cover plate 22. A plurality of flow channels 22 are arranged side by side on the base plate 21. The flow channels 22 are capillary flow channels. Here, the capillary flow channels refer to the smaller size of the flow channels. , specifically, the depth is 1mm~2mm, and the width is 0.3mm~3mm, which can further increase the distribution density of the runners. These runners are parallel to each other and distributed on the substrate 21 in a spiral manner. The flow channel 22 is a rectangular groove with a rectangular cross-section, and the starting ends of each flow channel are collected together and communicated with the liquid inlet 23 and the liquid outlet 24 of the co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap