Method of removing phenylalanine in rice proteins

A technology of rice protein and phenylalanine, applied in the direction of food science, etc., can solve the problems of cumbersome steps, long time-consuming, low economic benefits, etc., and achieve the effect of simple operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for removing phenylalanine in rice protein comprises the following steps:

[0040] The first step: fully dissolve the rice protein pretreatment;

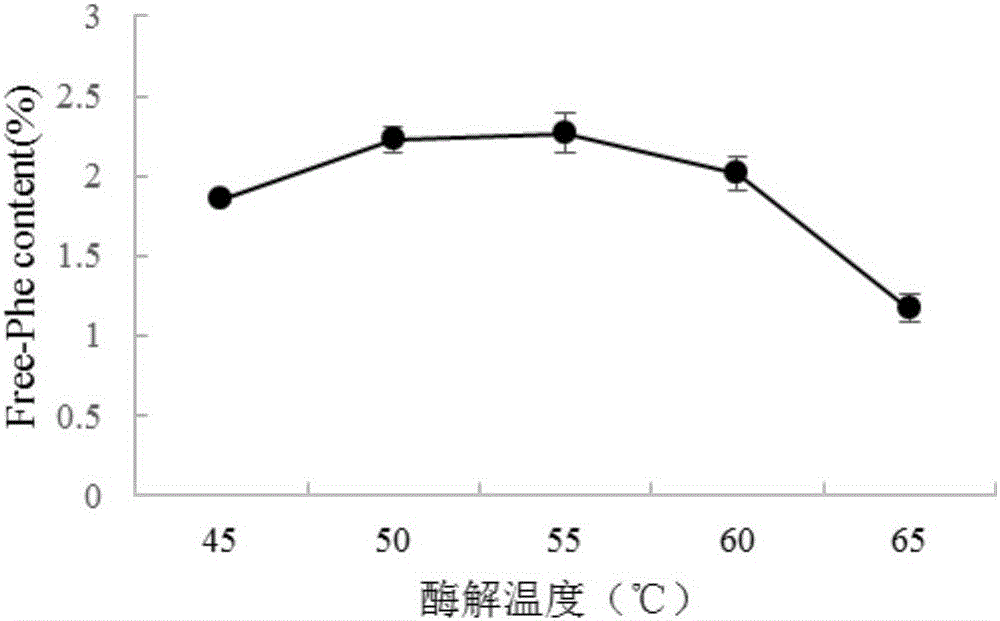

[0041]The second step: After the first step, the rice protein is fully dissolved, and chymotrypsin (addition amount 7200U / g protein) is added, and the enzymolysis is carried out in a constant temperature water bath shaker at 55°C for 6 hours;

[0042] Step 3: After the reaction in the second step, add pronase (98U / g protein) and mix evenly, and carry out enzymatic hydrolysis in a constant temperature water bath shaker at 45°C for 3 hours;

[0043] Step 4: Take it out after the reaction in the third step, put it in a constant temperature water bath at 90°C for 10 minutes to inactivate the protease, centrifuge at 4200r / min for 20 minutes, and take the supernatant to obtain the enzymatic hydrolyzate of rice protein;

[0044] Step 5: After the reaction in the fourth step, use D101 macroporous adsorption resin to adsor...

experiment example 1

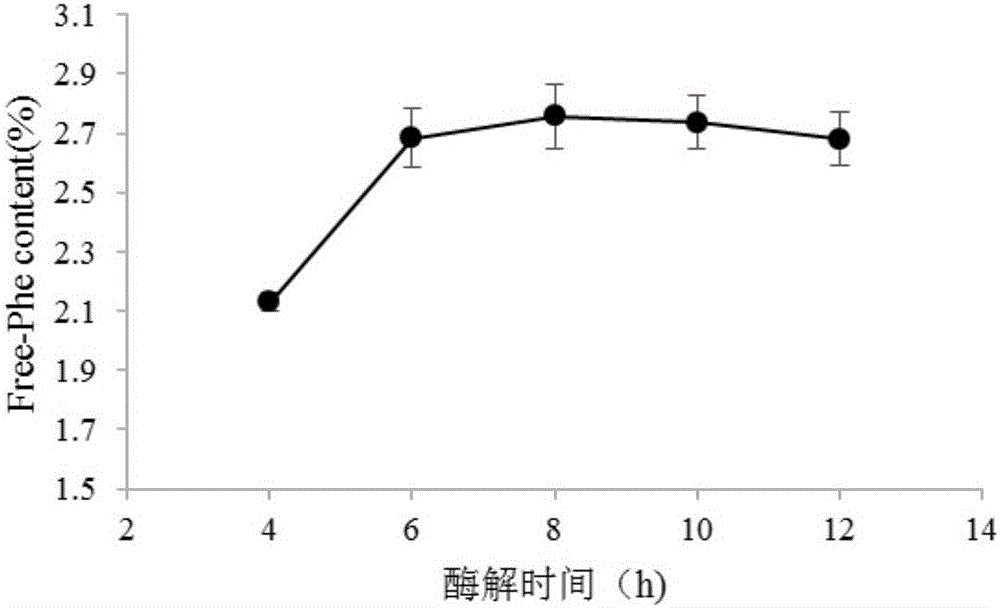

[0054] Experimental example 1 Effect of different enzymatic hydrolysis times of chymotrypsin on the free effect of phenylalanine

[0055] The first step: fully dissolve the rice protein pretreatment;

[0056] The second step: After the first step, the rice protein is fully dissolved, and chymotrypsin is added (7200U / g protein), and the enzymolysis is carried out in a constant temperature water bath shaker at 55°C (4h / 6h / 8h / 10h / 12h);

[0057] Step 3: After the reaction in the second step, take it out, put it in a constant temperature water bath at 90°C for 10 minutes to inactivate the protease, centrifuge at 4200r / min for 20 minutes, and take the supernatant to obtain the enzymatic hydrolyzate of rice protein;

[0058] Step 4: After the reaction in the third step is completed, the solution is a rice protein solution in which phenylalanine is fully free, and the solution is preserved by freeze-drying.

[0059] The results of the effect of different enzymatic hydrolysis times of...

experiment example 2

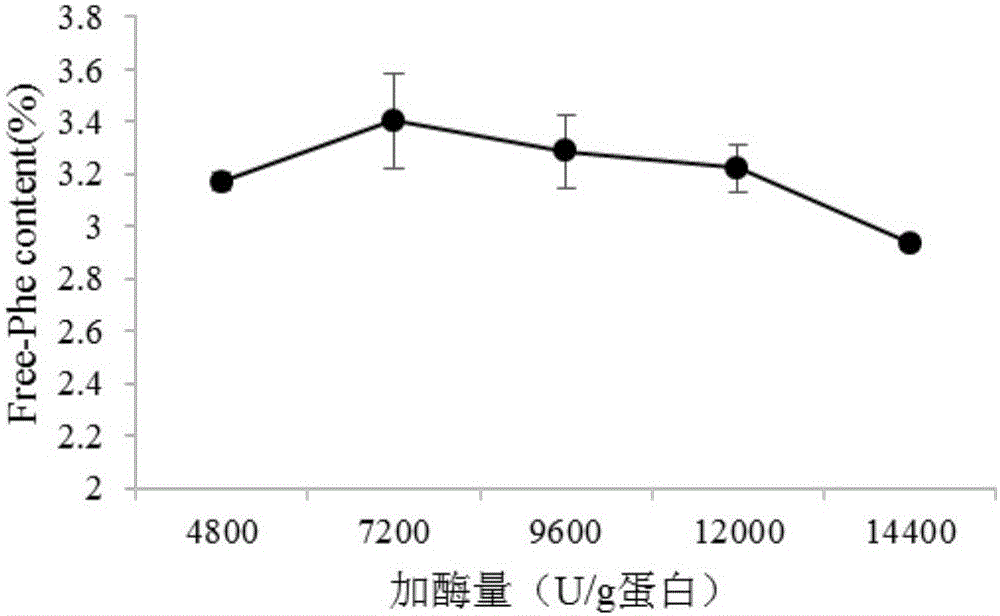

[0060] Influence of experimental example 2 chymotrypsin adding amount on the free effect of phenylalanine

[0061] The first step: fully dissolve the rice protein pretreatment;

[0062] The second step: After the first step, the rice protein is fully dissolved, and chymotrypsin (addition amount 4800-14400U / g protein) is added, and the enzymolysis is carried out in a constant temperature water bath shaker at 55°C for 6 hours;

[0063] Step 3: After the reaction in the second step, take it out, put it in a constant temperature water bath at 90°C for 10 minutes to inactivate the protease, centrifuge at 4200r / min for 20 minutes, and take the supernatant to obtain the enzymatic hydrolyzate of rice protein;

[0064] Step 4: After the reaction in the third step is completed, the solution is a rice protein solution in which phenylalanine is fully free, and the solution is preserved by freeze-drying.

[0065] The results of the effect of chymotrypsin addition on the free effect of phe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com