Rubber sheet rubberizing device

A technology for hanging glue and film, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of small contact surface, loose glue surface, short glue hanging time, etc. The effect of uniform glue and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

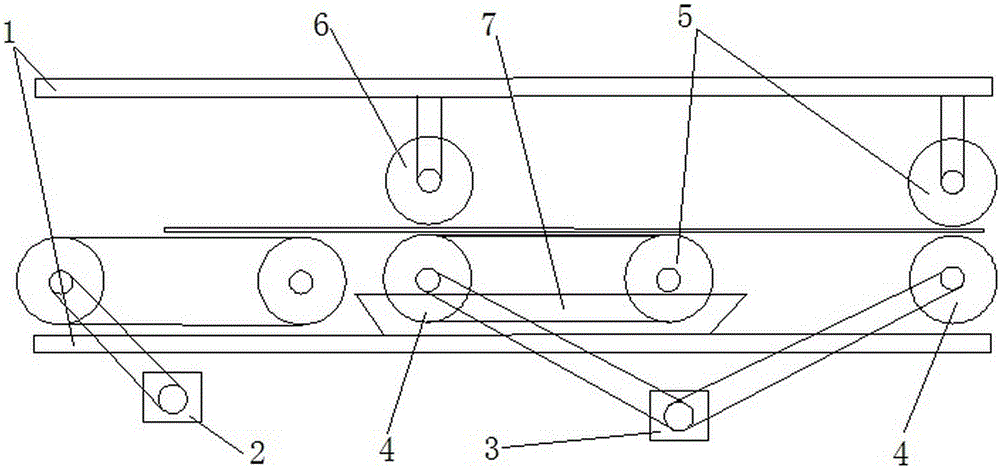

[0022] Such as figure 1 , a film gluing system, comprising a bracket 1 and a driving device 2, characterized in that: the bracket 2 is provided with a gluing device; the gluing device includes a driving motor 3, a traction wheel pair and at least one set of gluing Wheel set; said set of hanging rubber wheels includes a pair of driving wheels 4 and driven wheels 5, at least one pinch wheel 6 and a group of ring-shaped hanging tapes driven by driving wheels 4 and driven wheels 5; said hanging rubber wheels A glue pool 7 is arranged below the group, and the hanging tape is partly immersed in the glue pool 7; the pressing wheel is elastically arranged above the ring-shaped hanging tape.

[0023] This is one of the most basic embodiments of the present invention. The driving motor 3 drives the traction wheel pair and the rubber-hanging wheel group to drive the film to be glued. The part of the ring-shaped hanging tape immersed in the glue pool 7 will be lifted up and hung on the p...

Embodiment 2

[0025] Such as figure 1 , a film gluing system, comprising a bracket 1 and a driving device 2, characterized in that: the bracket 2 is provided with a gluing device; the gluing device includes a driving motor 3, a traction wheel pair and at least one set of gluing Wheel set; said set of hanging rubber wheels includes a pair of driving wheels 4 and driven wheels 5, at least one pinch wheel 6 and a group of ring-shaped hanging tapes driven by driving wheels 4 and driven wheels 5; said hanging rubber wheels A glue pool 7 is arranged below the group, and the hanging tape is partly immersed in the glue pool 7; the pressing wheel is elastically arranged above the ring-shaped hanging tape.

[0026] A heating device is provided at the bottom of the glue pool 7 .

[0027] This is a preferred embodiment of the invention. The driving motor 3 drives the traction wheel pair and the rubber-hanging wheel group to drive the film to be glued. The part of the ring-shaped hanging tape immersed...

Embodiment 3

[0029] Such as figure 1 , a film gluing system, comprising a bracket 1 and a driving device 2, characterized in that: the bracket 2 is provided with a gluing device; the gluing device includes a driving motor 3, a traction wheel pair and at least one set of gluing Wheel set; said set of hanging rubber wheels includes a pair of driving wheels 4 and driven wheels 5, at least one pinch wheel 6 and a group of ring-shaped hanging tapes driven by driving wheels 4 and driven wheels 5; said hanging rubber wheels A glue pool 7 is arranged below the group, and the hanging tape is partly immersed in the glue pool 7; the pressing wheel is elastically arranged above the ring-shaped hanging tape.

[0030] A heating device is provided at the bottom of the glue pool 7 .

[0031] The surface of the annular hanging tape is provided with glue grooves at intervals.

[0032] This is a preferred embodiment of the invention. The driving motor 3 drives the traction wheel pair and the rubber-hangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com