Hydraulic control system of vertical shearing machine

A hydraulic control system and shearing machine technology, applied in shearing devices, mechanical equipment, shearing machine equipment, etc., can solve the problems of low production efficiency of shearing waste, lack of workers, unsafe production, etc., and achieve easy automation. The effect of high operation, high production efficiency and work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

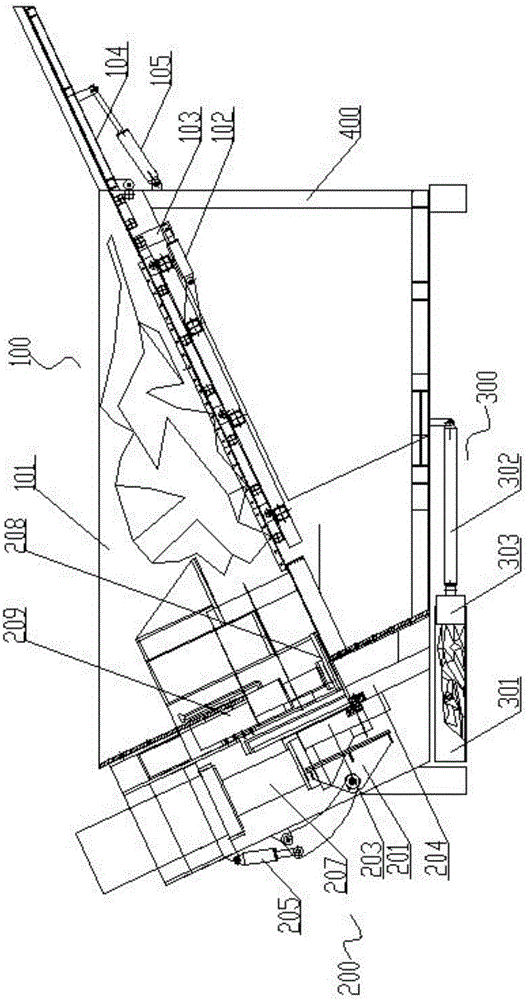

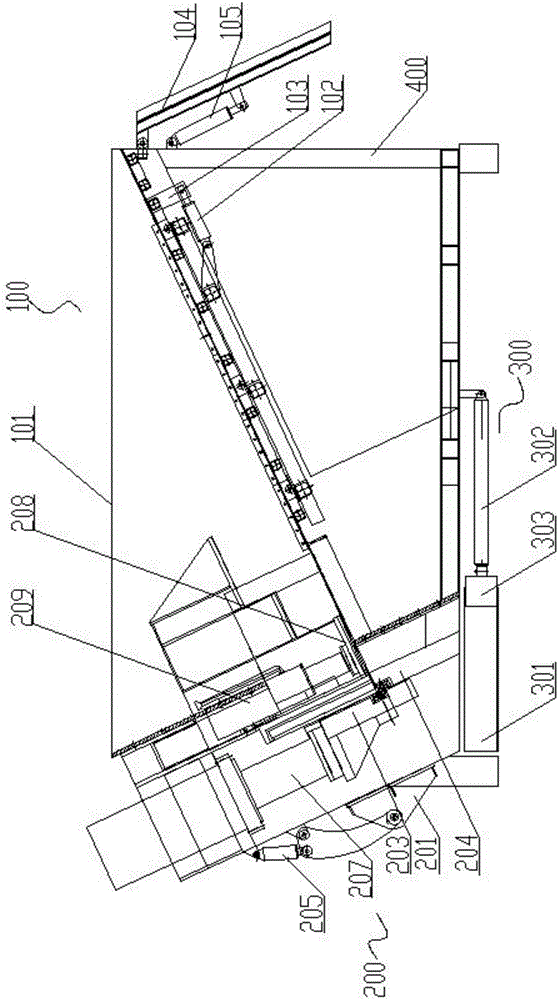

[0054] see Figure 1~Figure 3 , a vertical shearing machine related to the present invention, which includes a frame 400, a feeding device 100 and a shearing device 200 are arranged on the frame 400, the feeding device 100 is arranged obliquely backward and downward, and the shearing device The cutting device 200 is arranged obliquely forward and downward, and the feeding device 100 and the shearing device 200 are perpendicular to each other. A backward discharging device 300 is provided below the shearing device 200 . The vertical shearing machine also includes a hydraulic station and a hydraulic control system.

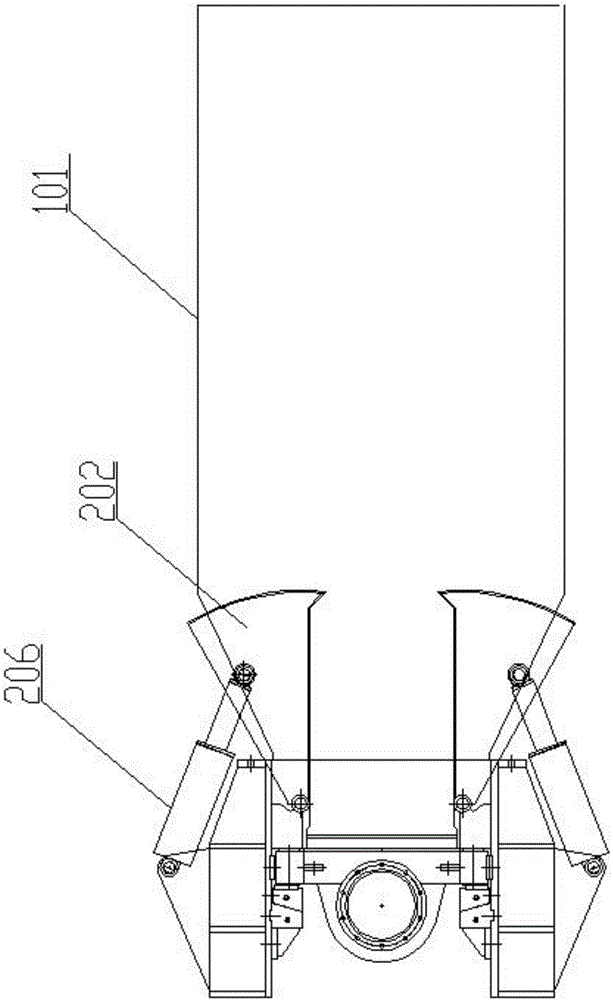

[0055] The feeding device 100 includes a feed box 101 inclined backward and downward, and the inclination angle of the feed box 1 is 25° to 30°. The feed box 101 includes side baffles on the left and right sides and an oblique slide plate below the side baffles. A slide plate vibrating cylinder 102 is hinged on the frame, and a piston rod end of the slide plate vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com