Spacer selecting machine for hanging plate spring seat

A suspension plate and pad selection machine technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient assembly process, low production efficiency and unstable quality of suspension plate spring seats, and achieve outstanding substantive characteristics. , Improve production efficiency, process optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

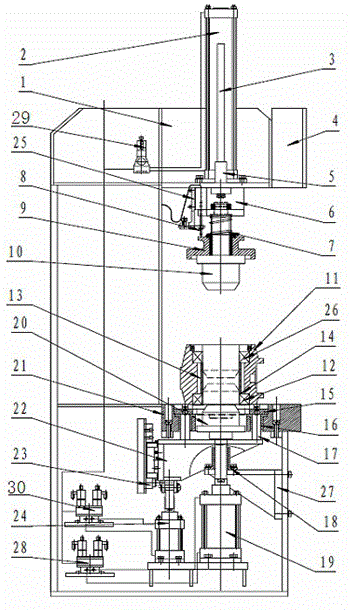

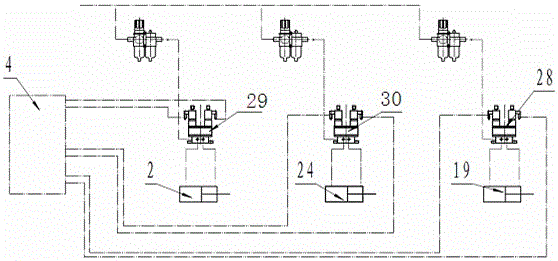

[0012] Example 1, see figure 1 , 2 According to the design requirements, it is processed into a frame 1, and a top piece cylinder 19, a lower pressure head 20, a vibrating cylinder 24, a vibrating support 22, a linear bearing 23, a guide shaft 17, a first linear bushing 16, Guide bracket 27, push plate 15 and workbench 21; Install lower pressure head 20 on top piece cylinder 19, in order to make lower pressure head 20 rise and fall smoothly, guide sleeve 18 is installed on guide bracket 27, on vibration cylinder 24 The vibrating support 22 is installed, and in order to ensure that the vibrating support 22 runs smoothly, a linear bearing 23 is installed on the back of the vibrating support 22, and the guide rail of the linear bearing 23 is installed on the frame 1; On the plate 15, the end surface of the guide shaft 17 is in contact with the upper plane of the vibrating support 22; the first linear bushing 16 is installed in the groove of the worktable 21;

[0013] Install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com