Special machine tool for polishing and polishing method thereof

A special machine tool and polishing brush technology, which is applied to surface polishing machine tools, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as difficult removal of burrs, damage to workpiece turning lines, labor-consuming and time-consuming problems, and achieve The effect of rapid polishing and prevention of damage to the surface of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

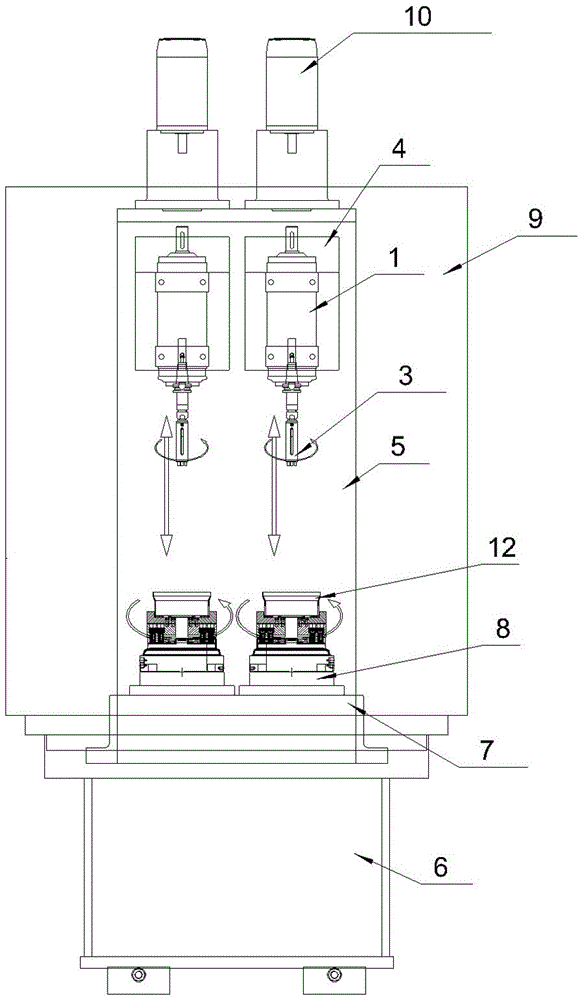

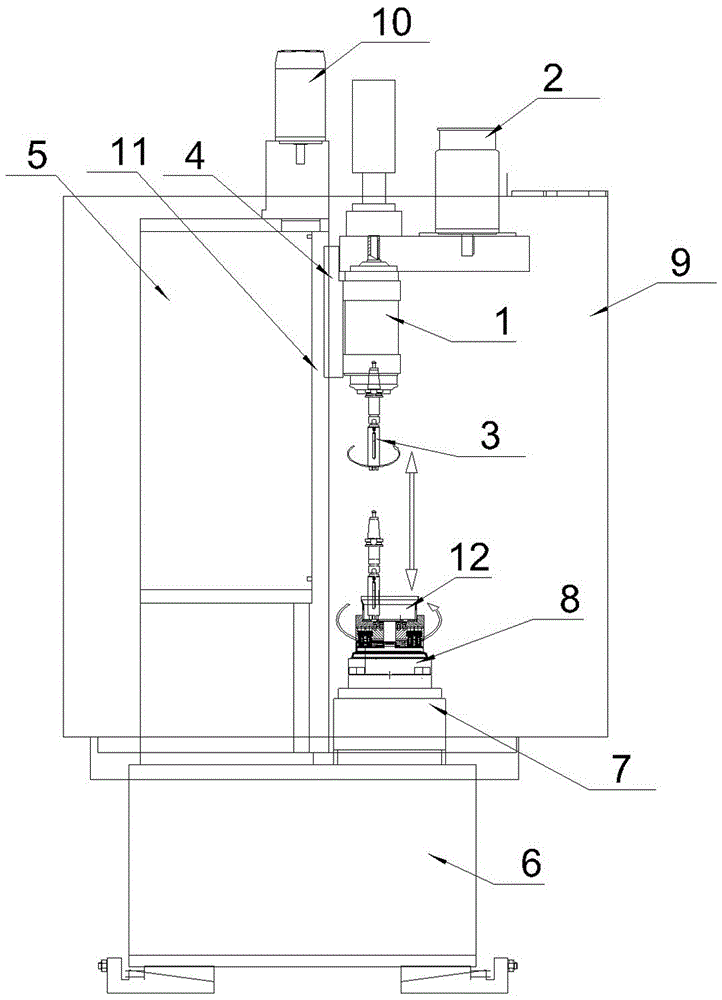

[0034] Such as figure 1 and 2 As shown, a special machine tool for polishing includes a main shaft 1, a main shaft driving device 2, a polishing brush 3, a lifting slide 4, a bed 5, a base 6, a workbench 7, a rotary chuck 8 and a protective cover 9, The bed 5 stands upright on the base 6, the protective cover 9 and the workbench 7 are installed on the base 6, the lifting slide 4 is installed in front of the bed 5, the sliding table driving device 10 is installed on the top of the bed 5, and the spindle 1 is installed on the On the lifting slide 4, a spindle driving device 2 is arranged above the spindle 1, the polishing brush 3 is installed in the tool mounting hole of the spindle 1, and the rotary chuck 8 is installed on the workbench 7.

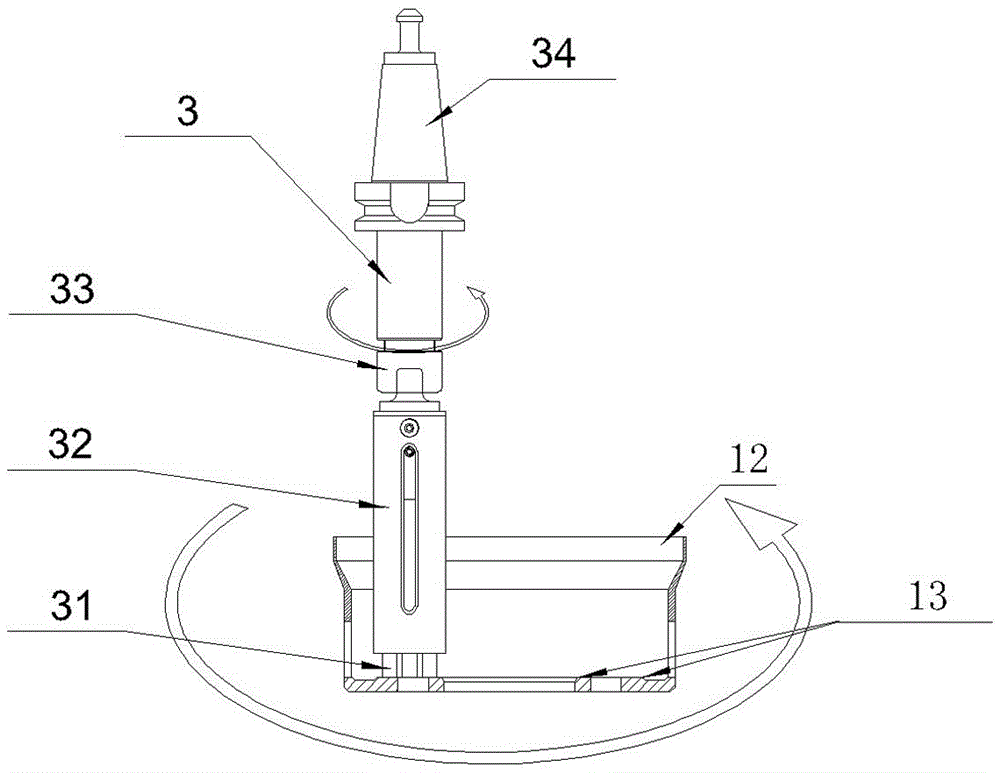

[0035] Such as image 3 As shown, the polishing brush 3 includes a brush 31 , a sleeve 32 , a rod 33 and a handle 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com