Material splitting method and material splitting device

A cutting device and wood technology, which is applied in sawing equipment, wood processing equipment, circular saws, etc., can solve the problems of high price, utilization of corner waste, waste of resources, etc., achieve high work efficiency, save production costs, and solve waste problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

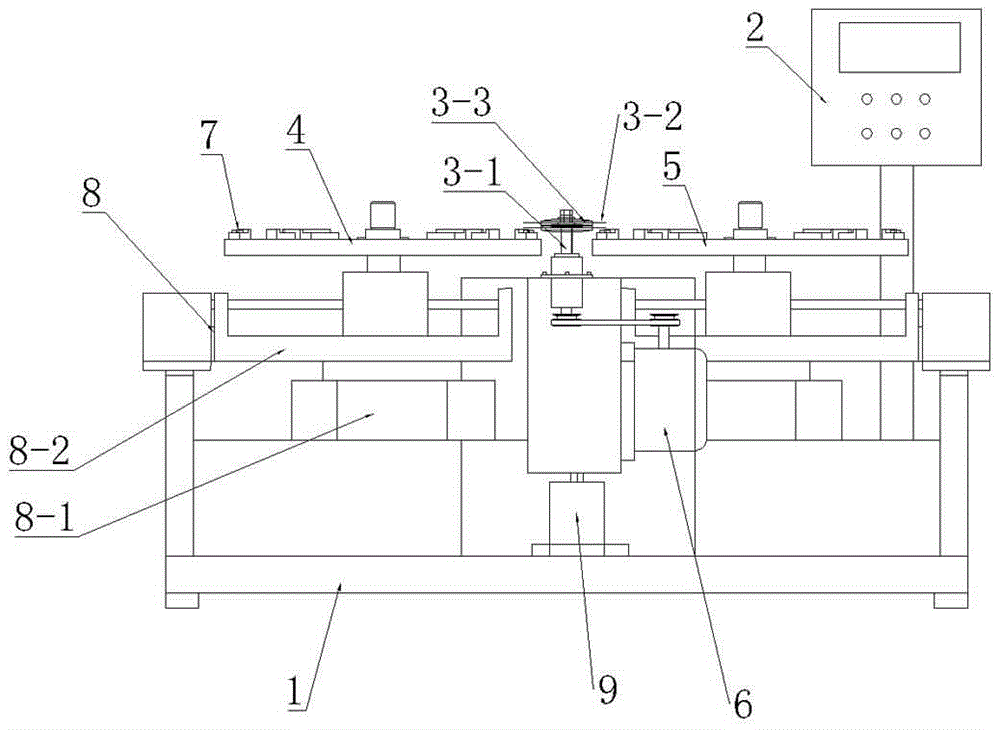

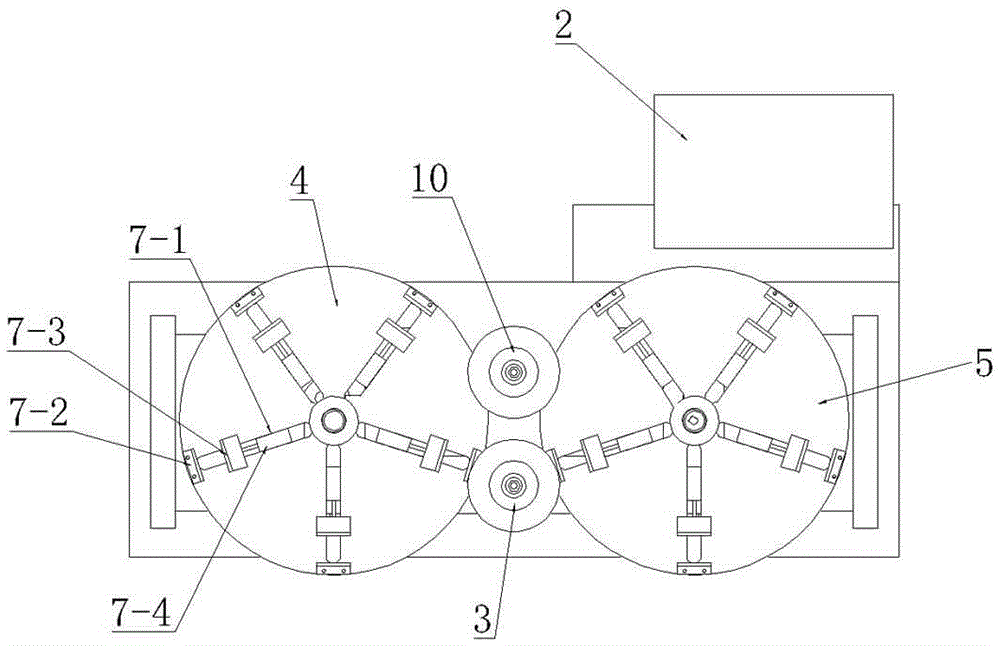

[0021] The present invention relates to a material cutting method, which uses a disc main cutting device as the cutting center of corner wood, and at least two rotating worktables capable of self-rotation are arranged around the outer side of the main disc cutting device. A plurality of fixtures for clamping corner wood are arranged in the circumferential direction of the rotary table, so that each rotary table drives the corner wood on the fixture to move closer to the main disc cutting device for cutting while rotating; Disc cutting device. In the vertical direction, the cutting height of the planetary disc cutting device is smaller than that of the main disc cutting device. After cutting by the main disk cutting device, it enters the cutting station of the planetary disk cutting device to realize the fine cutting of edge wood. Before processing, it is necessary to adjust the relative position between the cutter of the control disc main cutting device and the rotary table to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com