Polystyrene board positioning machine

A positioning machine and benzene plate technology, applied in the direction of conveyor objects, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of improving work efficiency and maximizing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

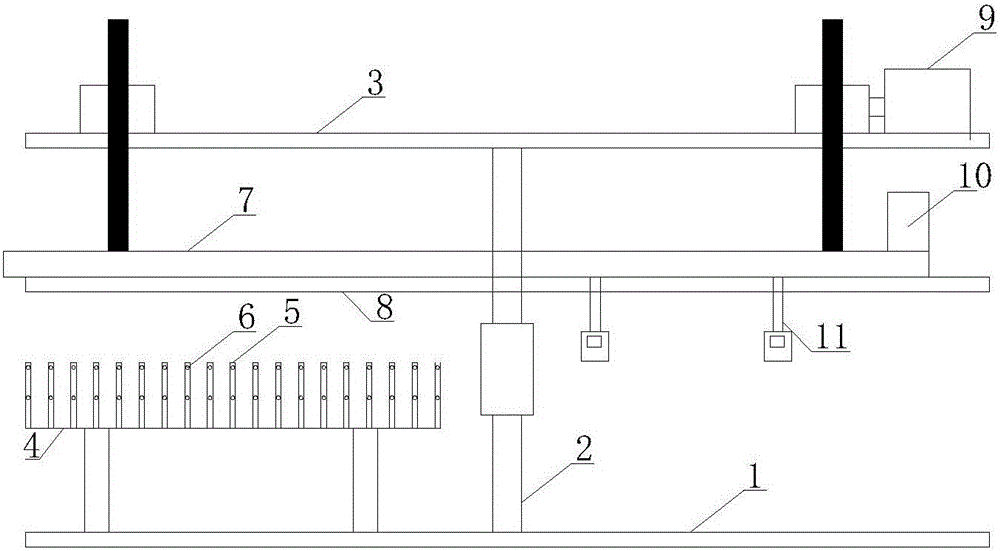

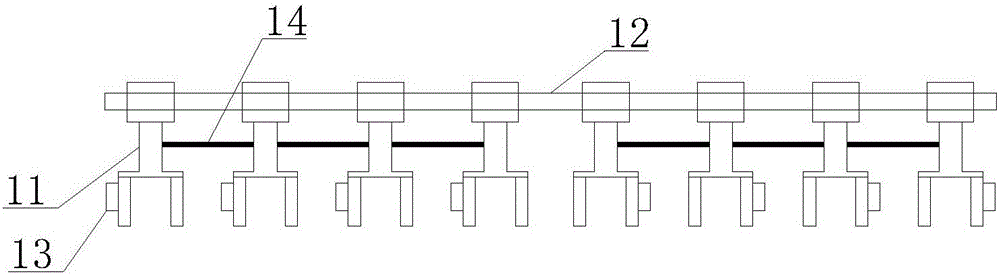

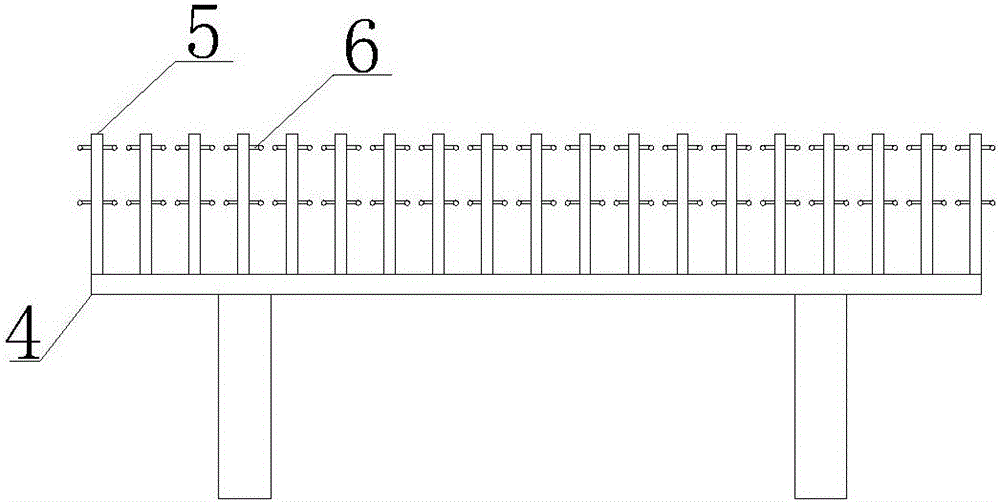

[0022] Such as Figure 1 to Figure 3 A kind of benzene board positioning machine shown, comprises frame, walking device and several gripper groups 11; Frame comprises base 1, bracket 2 and roof beam 3, roof beam 3 is connected and fixed with base 1 through bracket 2 and base 1 The planes where the top beams 3 are located are parallel to each other, the base 1 is provided with a working platform 4, and the working platform 4 is provided with at least two sets of spacer piles 5, and each set of spacer piles 5 consists of several There are 5 sets of limit piles, each limit pile is provided with a number of limit strips 6, and the plane where the limit strips 6 on each limit pile are co-located is perpendicular to the plane where each limit pile group 5 is located , each limit bar 6 ends are provided with elastic balls; the traveling device includes an up and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com