A kind of mud for high-pressure grouting molding

A high-pressure grouting and mud technology, applied in the field of ceramic manufacturing, can solve problems such as inability to adapt to high-pressure forming, and achieve the effects of shortening the time for filling the mold and the time for discharging mud, increasing the cracking time, and shortening the molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

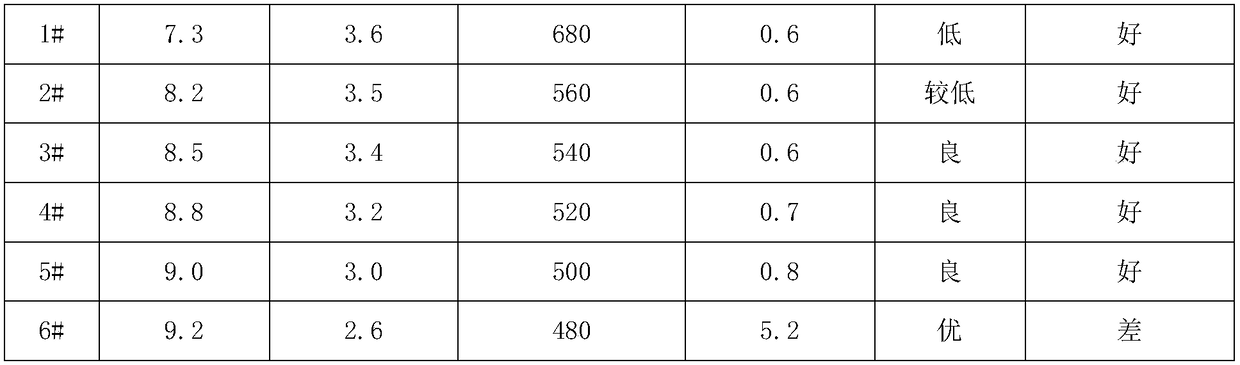

Examples

Embodiment Construction

[0013] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0014] The invention provides a kind of mud for high-pressure grouting molding. Its preparation method is to prepare mud first, and the components of the mud include water-washed china clay 15.3-20%, Guangdong black mud 5.2-5.6%, and kaolin 20-23% by weight. %, porcelain stone 27-29%, calcined kaolin 6-10%, feldspar 16-19%, dolomite 2-2.5%. Among them, the nature of water-washed china clay is illite-type clay, which has good plasticity and improves the cracking time of mud. The place of production is Jiefu, Yongchun, Fujian, and you can choose Fujian Kefu Material Co., Ltd. Ka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com