A kind of anti-fatigue health pad adopting rubber foam material and preparation method thereof

A rubber foaming and anti-fatigue technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of unsatisfactory hardness and resilience, and the inability to ensure plastic additives and solvents, etc., to achieve decorative effects Good, low production cost, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

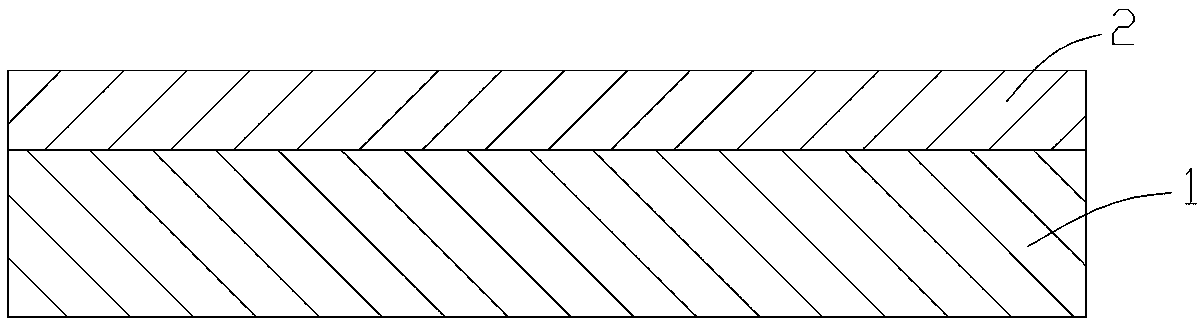

[0028] Such as figure 1 Shown, a kind of anti-fatigue healthy pad that adopts rubber foam material, comprises rubber foam layer 1 and the fabric layer 2 that is compounded on described rubber foam layer, and described rubber foam layer comprises the raw material of following weight portion: Unvulcanized rubber 22, filler 48, oil agent 18, vulcanizing agent 2, accelerator 4.5, anti-aging agent 0.5, foaming agent 4, dispersant 1.

Embodiment 2

[0030] The difference from Example 1 is that the rubber foam layer includes the following raw materials in parts by weight: unvulcanized rubber 58, filler 12, oil agent 6, vulcanizing agent 5, accelerator 5, anti-aging agent 3, foaming agent 6, dispersion Agent 5.

Embodiment 3

[0032] The difference from Example 1 is that the rubber foam layer includes the following raw materials in parts by weight: unvulcanized rubber 40, filler 33, oil agent 12, vulcanizing agent 4, accelerator 1.5, anti-aging agent 2.5, foaming agent 2.5, dispersion Agent 4.5.

[0033] The fabric layer in embodiment 1-3 is made by natural fiber or synthetic fiber through tufting process or weaving process or non-woven process or flocking process, and can according to the occasion of use and the forming style of fabric, in the fabric layer The surface uses spray printing, pad printing, screen printing and other techniques to print various patterns, and according to the different requirements of the use environment and functions, the thickness of the rubber foam layer can be from 1-16mm, so as to control the resistance The overall thickness of the fatigue health pad.

[0034] Wherein, the unvulcanized rubber is one or more of natural rubber, styrene-butadiene rubber, nitrile-butadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com