Petroleum hydrocarbon degrading strain, petroleum hydrocarbon degrading microbial agent, as well as preparation method and applications of petroleum hydrocarbon degrading microbial agent

A petroleum hydrocarbon degrading bacteria and petroleum hydrocarbon technology, which is applied in the field of petroleum pollution control, can solve problems affecting the repair effect, achieve efficient degradation, broad application prospects, and good commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a preparation method of a petroleum hydrocarbon degrading bacterial agent, comprising the following steps:

[0026] The petroleum hydrocarbon degrading strain Acinetobacter sp. LCL-1 was inserted into the petroleum degrading medium of the fermenter according to the inoculum amount of 10% by volume, and then placed in a shaking table at 150-200 rpm, at a temperature of 25- Cultivate for 3-7 days under the conditions of 35° C., salinity of 1-3.5%, and pH of 6-8 to obtain the oil-degrading bacterial agent, wherein the composition of the oil-degrading medium is 1% (w / v) KH 2 PO 4 , 1% (w / v) of K 2 HPO 4 , 1% (w / v) NH 4 NO 3 , 0.2% (w / v) MgSO 4 , 0.02% (w / v) CaCl 2 , 0.05%(w / v) FeCl 2 , 25% (w / v) NaCl and 0.5% (w / v) petroleum.

[0027] The above-mentioned petroleum-degrading bacterial agent can be used for the degradation of petroleum.

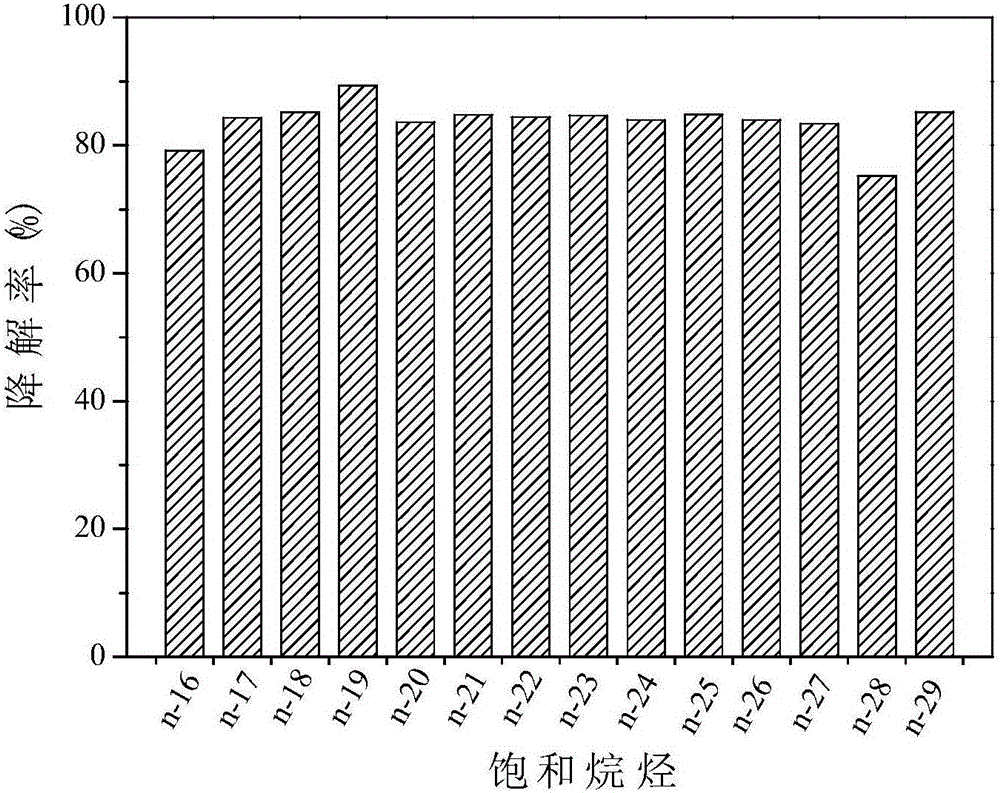

[0028] see figure 1 is the degradation rate of petroleum hydrocarbons in crude oil by Acinet...

Embodiment 1

[0036] Example 1 - Preparation of Amine Modified Polyurethane Foam:

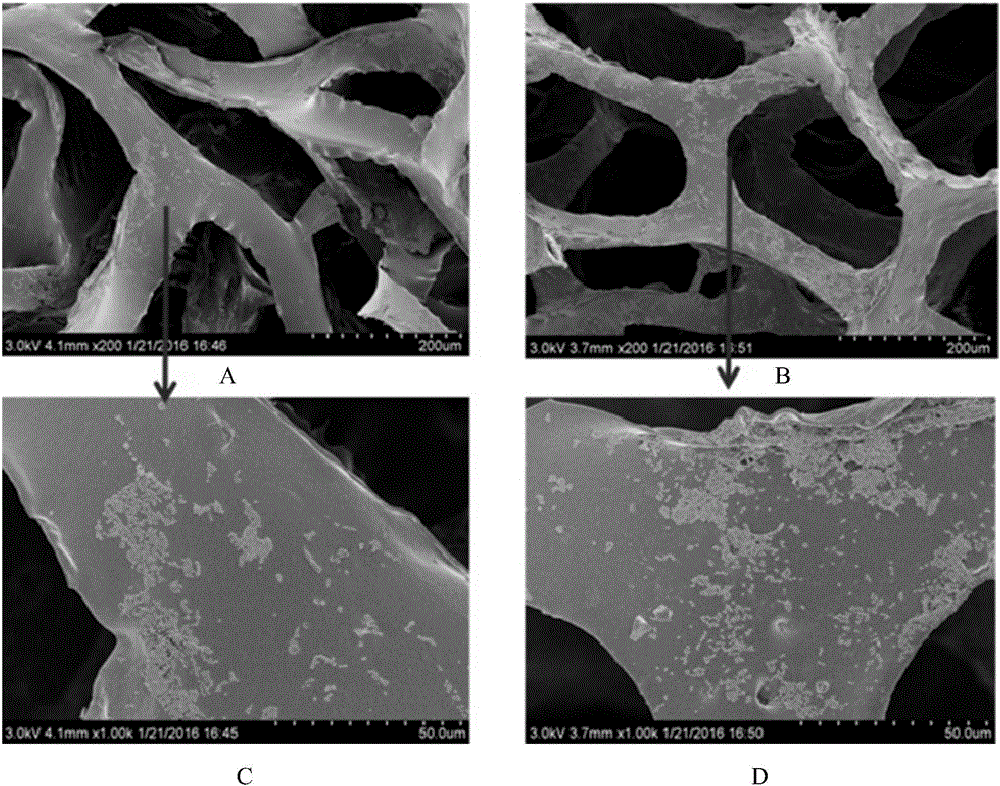

[0037] Cut the polyurethane foam into small pieces of 1cm×1cm, take five pieces (0.5901g) and disperse them in 99mL of deionized water, add ~1.4mL of ammonia water to adjust the pH to ~10, and add 1mL of diethylenetriamine (mass) when the temperature rises to 30°C. ratio ~ 59%), stirred and reacted for 6h, and vacuum-dried to obtain graphene containing amino groups; immobilization of LCL-1: add five blocks of amine-modified polyurethane foam to 100 mL of LB medium, and connect it at a V / V ratio of 1%. After adding LCL-1 seed solution, it was placed at 30°C and 180rpm for cross-linking reaction for 72h. At this time, the fixed amount of microorganisms was about 83.55 mg / g (see figure 2 A and C).

Embodiment 2

[0038] Example 2 - Preparation of Amine-Modified Polyurethane Foam:

[0039] Cut the polyurethane foam into small pieces of 1cm×1cm, take five pieces (0.6033g) and disperse them in 50mL deionized water, add ~0.7mL ammonia water to adjust the pH to ~10, and add 50mL diethylenetriamine (mass) when the temperature rises to 30°C. ratio ~ 1.2%), stirring and reacting for 6 hours, and vacuum drying to obtain graphene containing amino groups; ② Immobilization of LCL-1: add five pieces of amine-modified polyurethane foam to 100 mL of LB medium, and connect it at a V / V ratio of 1%. After adding LCL-1 seed solution, the cross-linking reaction was carried out at 30°C and 180rpm for 72h. The microbial immobilization amount at this time was about 130.8 mg / g (see figure 2 B and D).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com