A kind of energy-saving and high-efficiency loose rope washing process and device

A rope-like, loose-type technology, applied in the processing of textile materials, textile processing machine accessories, continuous processing of textile materials, etc., can solve the problems of water consumption and steam consumption, and achieve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

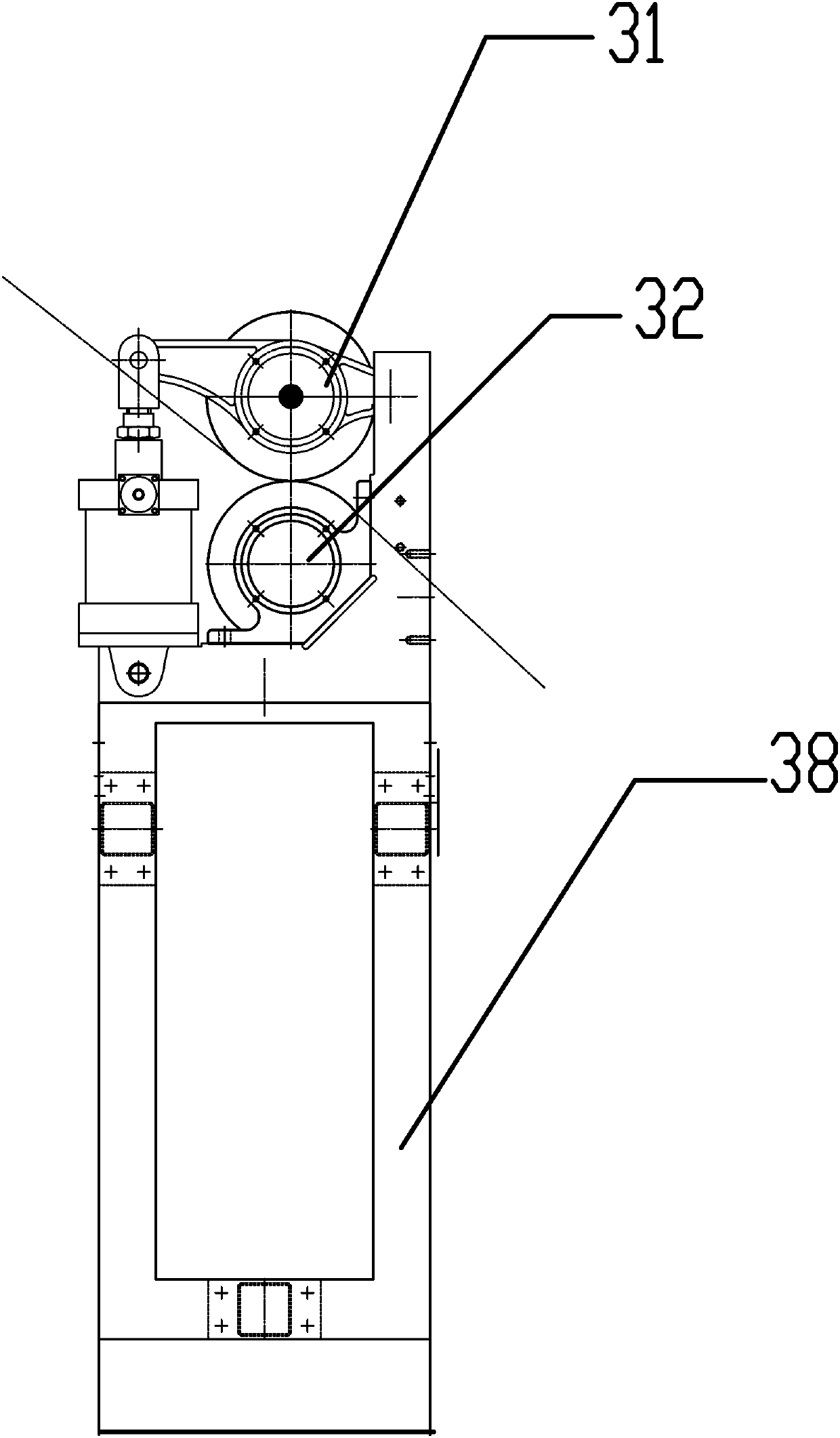

[0040] The heating principle of the drying cylinder described in this article is the use of steam heating. The steam is introduced into the steam pipe of the dryer from the steam main pipe and introduced into each drying cylinder. Each steam inlet pipe is equipped with a regulating valve, a safety valve and a pressure gauge. When the steam pressure per unit area exceeds the specified pressure, the safety valve will automatically open to release over-pressure steam. The steam entering the drying cylinder transfers heat to the drying cylinder, and then from the surface of the drying cylinder to the water-containing fabric surrounding the surface of the drying cylinder, the steam is condensed into water due to the loss of heat, and the condensed water is discharged from the drying hopper or siphon. Into the drain pipe.

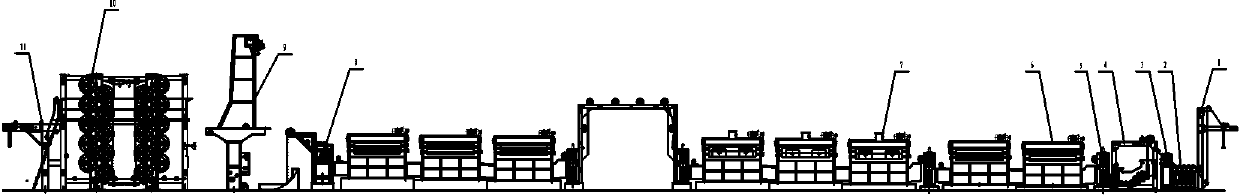

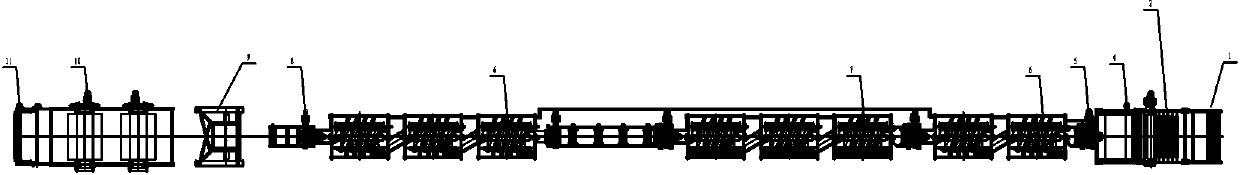

[0041] An energy-saving and efficient loose-type rope washing device (such as Figure 1-8 As shown), according to the direction of fabric feeding, set the open-wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com