Method for recycling plastic products by virtue of built-in structure

A product and plastic technology, used in the field of recycling and sorting plastic products relying on built-in structures, can solve problems such as damage, product appearance impact, inability to identify plastic varieties, and achieve the effect of improving efficiency and widening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The product adopts a cup product, including a cup body 29, three first accommodating cavities 30 arranged on the outer wall of the cup body 29, and a sealing cover 31 arranged on the outer wall of the cup body 29 and used for sealing the first accommodating cavities 30 .

[0037] A method of recycling and sorting plastic products that relies on built-in structures, the specific steps are as follows:

[0038] 1) When designing the product, add a built-in structure inside the product; during the production process of the product, inject different color dyes into the built-in structure according to the recycling characteristics of the product material, and seal the built-in structure;

[0039] 2) Recycle the waste products of the above-mentioned products after use, and clean and dry them;

[0040] 3) Put the waste products into the feeding hopper of the dyeing pulverizer, and the waste products fall into the corresponding crushing channels of different sizes along the par...

Embodiment 2

[0049] The product adopts a box product, including a box body 32, a second accommodating cavity 33 arranged around and at the bottom of the box body 32, and a sealing plug 34 arranged around and at the bottom of the box body 32 and used for sealing the second accommodating cavity 33 There are four second accommodating cavities 33 at the bottom of the box body 32, which are centrally symmetrically distributed, and each of the four side walls of the box body 32 has a second accommodating cavity 33, which are centrally symmetrically distributed .

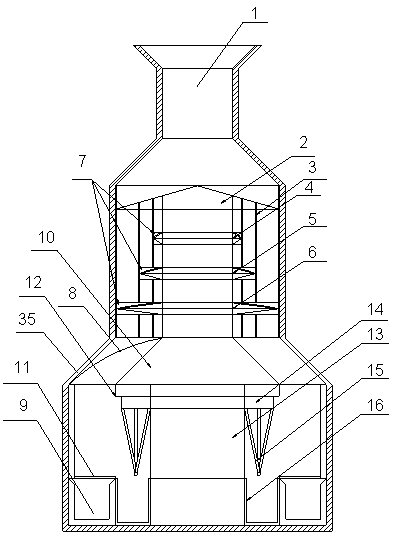

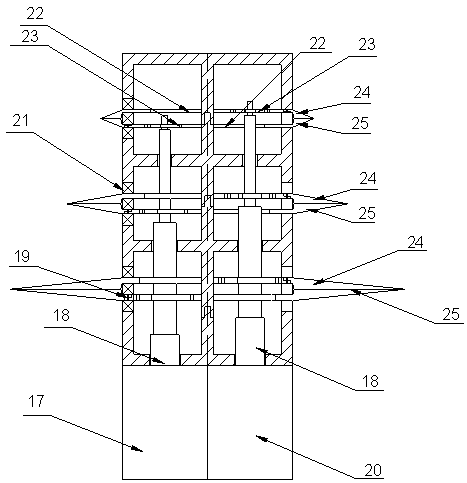

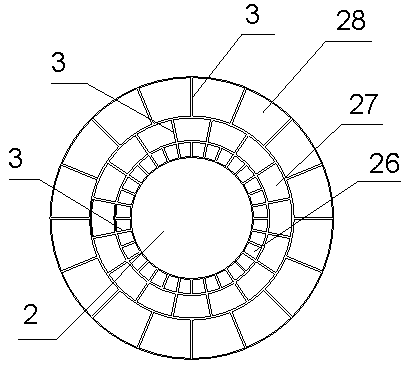

[0050] The dyeing pulverizer includes a shell, a feeding hopper 1 arranged on the top of the casing, a partition plate 2 arranged below the feeding hopper 1, a group of crushing passages arranged on the periphery of the partition plate 2, and a group of crushing channels arranged under the partition plate 2 and extending The cutting device in the crushing channel, the crushing channel adopts a ring structure and is provided with three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com