A Tower-Win Integrated Converter Gas Purification Tower

A converter gas, integrated technology, applied in combustible gas purification, combustible gas purification/transformation, manufacturing converters, etc., can solve the problems of high temperature at the inlet section, unstable work, large water consumption, etc., and achieve high dust removal efficiency, Elimination of thermal deformation stress and installation errors, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

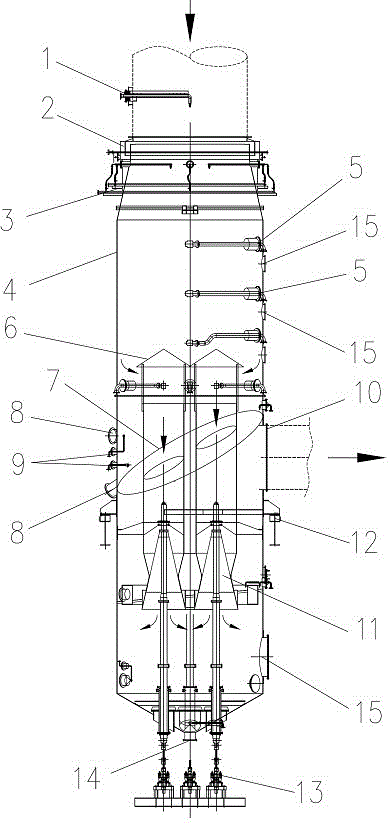

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] see figure 1 As shown, the Tawen integrated converter gas purification tower mainly consists of a tower body 4, an overflow water seal 2, a primary spray gun 1, a double-flow atomization spray section 3, a two-way spray section 5, an annular gap device 11 and Hydraulic mechanism 13 is made up of, wherein:

[0022] The overflow water seal 2 is an annular basin structure with an annular water inlet pipe around it and a liquid level alarm device at the bottom, wherein a flange is provided at the inlet of the water inlet pipe;

[0023] The first-stage spray gun 1 is arranged on the upper part of the overflow water seal 2 and includes a slag retaining plate, a cooling pipe, a baffle plate and a supporting member. The first-stage spray gun 1 initially cools the high-temperature gas, and simultaneously Seal the inlet pipe and flange to cool down;

[0024] The do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com