Construction method of hanging and connecting precast concrete external protection sandwich wall panels

A technology of prefabricated concrete and construction method, applied in the direction of walls, building components, buildings, etc., can solve the problems of large initial installation deviation, easy collision, and time-consuming, etc., to achieve simple and flexible operation, ensure smooth installation, and improve efficiency. and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

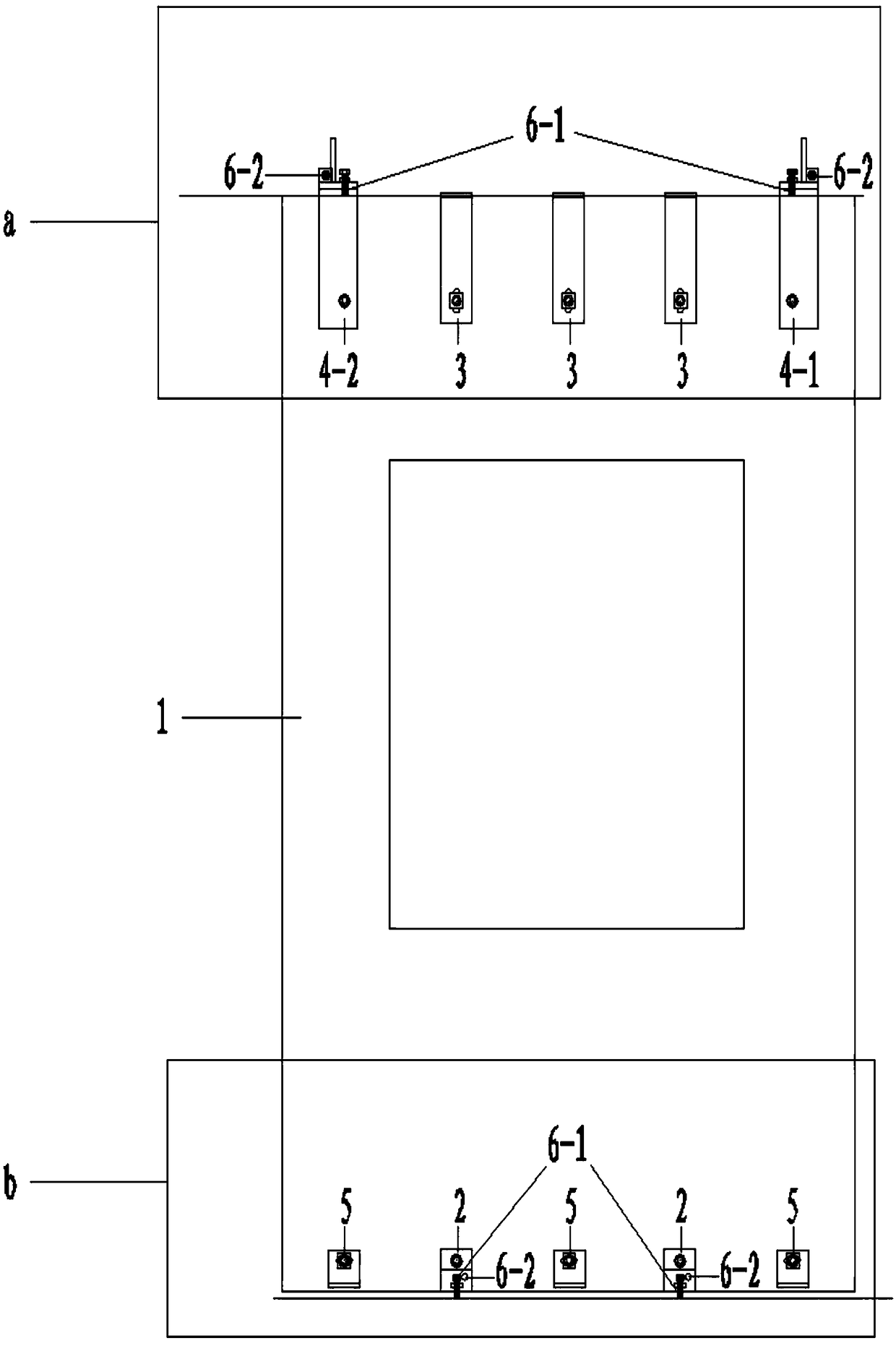

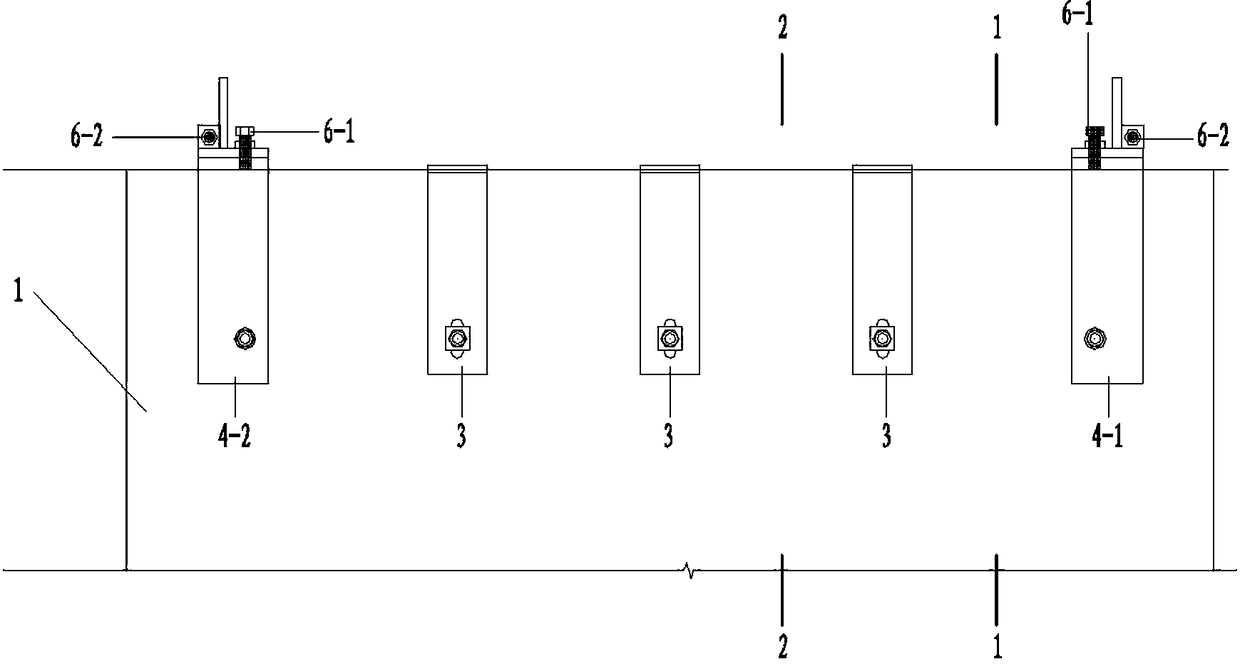

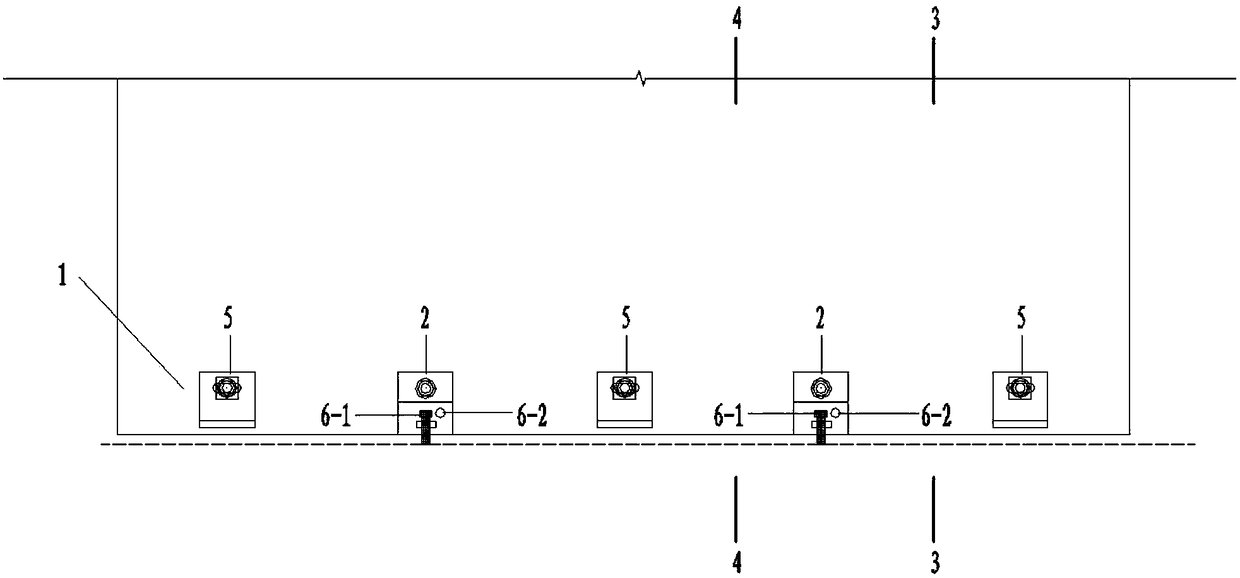

[0075] (1) The upper part of the prefabricated concrete sandwich wall panels 1 to be hung on the floor of the concrete main structure 8 is respectively connected with the fourth connector 4-2 and the first connector 4 by bolts on both sides along the transverse direction -1, on the prefabricated concrete sandwich wall panel 1 between the fourth connecting member 4-2 and the first connecting member 4-1, a plurality of third connecting members 3 are connected at intervals by bolts and prefabricated in multiple pieces The lower part of the concrete sandwich wall panel 1 is respectively connected with fifth connecting parts 5 by bolts on both sides along the transverse direction, and the prefabricated concrete sandwich wall panels 1 between the fifth connecting parts 5 on both sides are alternately connected by bolts. The second connector 2 and the fifth connector 5 are connected at intervals; the upper connector and the lower connector of the precast concrete sandwich wall panel 1...

Embodiment 2

[0102] (1) The upper part of the prefabricated concrete sandwich wall panels 1 to be hung on the floor of the concrete main structure 8 is respectively connected with the fourth connector 4-2 and the first connector 4 by bolts on both sides along the transverse direction -1, on the prefabricated concrete sandwich wall panel 1 between the fourth connecting member 4-2 and the first connecting member 4-1, a plurality of third connecting members 3 are connected at intervals by bolts and prefabricated in multiple pieces The lower part of the concrete sandwich wall panel 1 is respectively connected with fifth connecting parts 5 by bolts on both sides along the transverse direction, and the prefabricated concrete sandwich wall panels 1 between the fifth connecting parts 5 on both sides are alternately connected by bolts. The second connector 2 and the fifth connector 5 are connected at intervals; the upper connector and the lower connector of the precast concrete sandwich wall panel 1...

Embodiment 3

[0129] (1) The upper part of the prefabricated concrete sandwich wall panels 1 to be hung on the floor of the concrete main structure 8 is respectively connected with the fourth connector 4-2 and the first connector 4 by bolts on both sides along the transverse direction -1, on the prefabricated concrete sandwich wall panel 1 between the fourth connecting member 4-2 and the first connecting member 4-1, a plurality of third connecting members 3 are connected at intervals by bolts and prefabricated in multiple pieces The lower part of the concrete sandwich wall panel 1 is respectively connected with fifth connecting parts 5 by bolts on both sides along the transverse direction, and the prefabricated concrete sandwich wall panels 1 between the fifth connecting parts 5 on both sides are alternately connected by bolts. The second connector 2 and the fifth connector 5 are connected at intervals; the upper connector and the lower connector of the precast concrete sandwich wall panel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com