Step type structure filling method for second mining of coal pillars of remnant mining areas

A legacy coal pillar and step-type technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of surface subsidence buildings, damage and damage of railways and water bodies, and "domino instability and damage of stope filling bodies"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are intended to illustrate and explain the present invention, but not to limit the scope of the present invention.

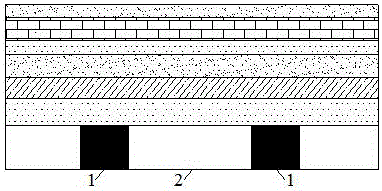

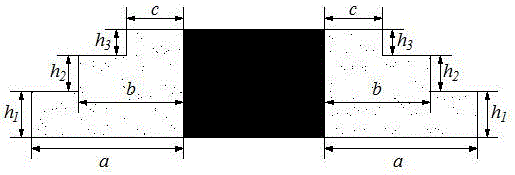

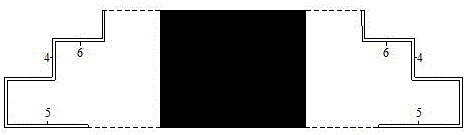

[0032] In order to have a clearer understanding of the technical objectives, features and effects of the present invention, a method for filling the remaining coal pillars in the residual mining area with stepped structure will be further described in detail in conjunction with the accompanying drawings.

[0033] Madiwan Coal Mine is a typical resource-short old mine in Loufan County, facing many problems such as stabilizing production, increasing productivity and improving economic benefits. In the 1980s, the No. 9 coal seam of Madiwan Coal Mine was mined by the knife pillar method, which left a large number of coal pillar groups in the knife pillar residual mining area. The remaining coal pillars in the knife-pillar residual mining area of No. 9 coal seam have good re-mining and recovery value, and have increasingly become the foc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com