A fuel injector integrating an electronically controlled unit pump

A single unit pump and fuel injector technology, which is applied in fuel injection devices, machines/engines, charging systems, etc., to achieve the effects of convenient processing, reduced processing difficulty and cost, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

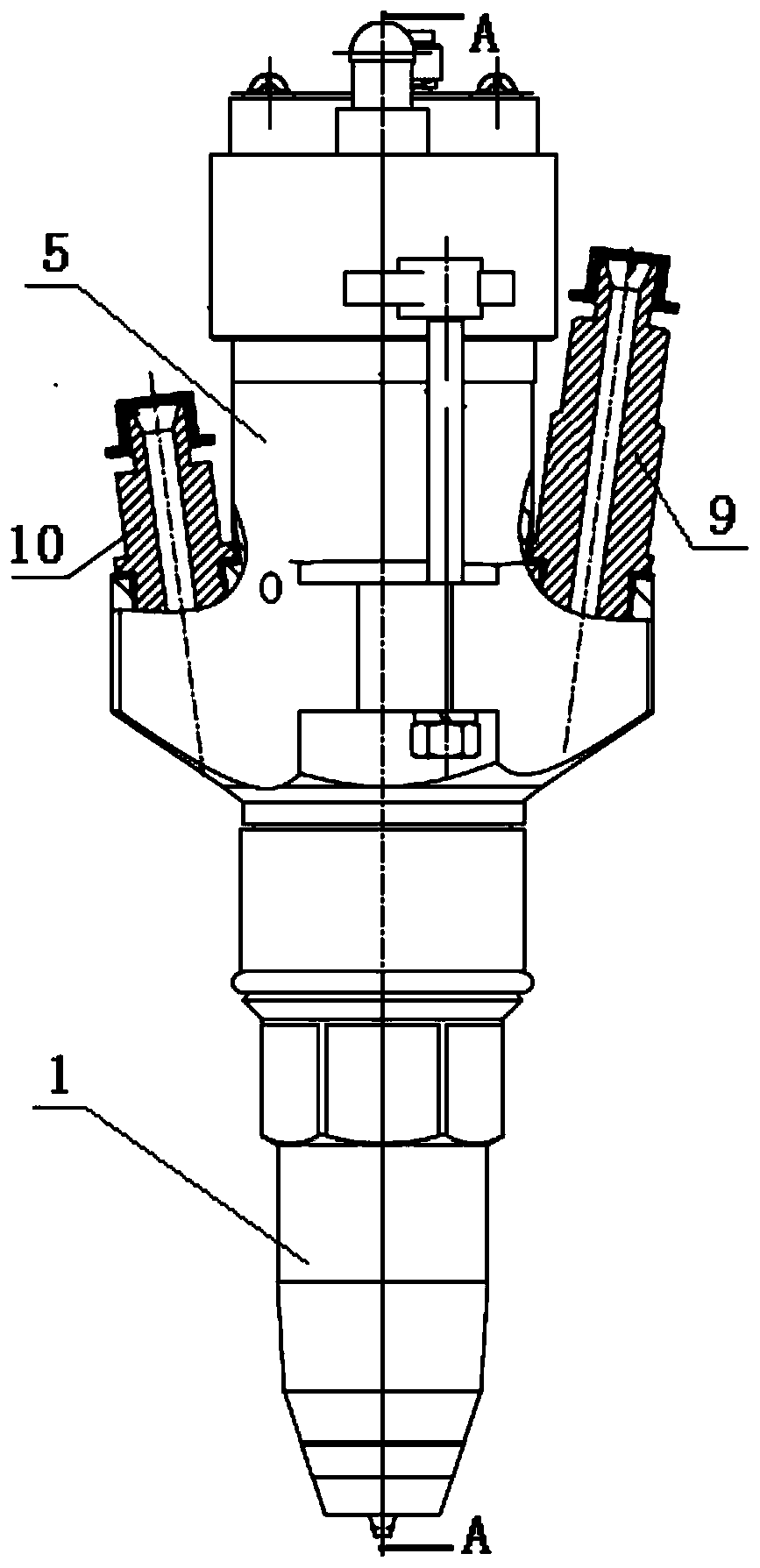

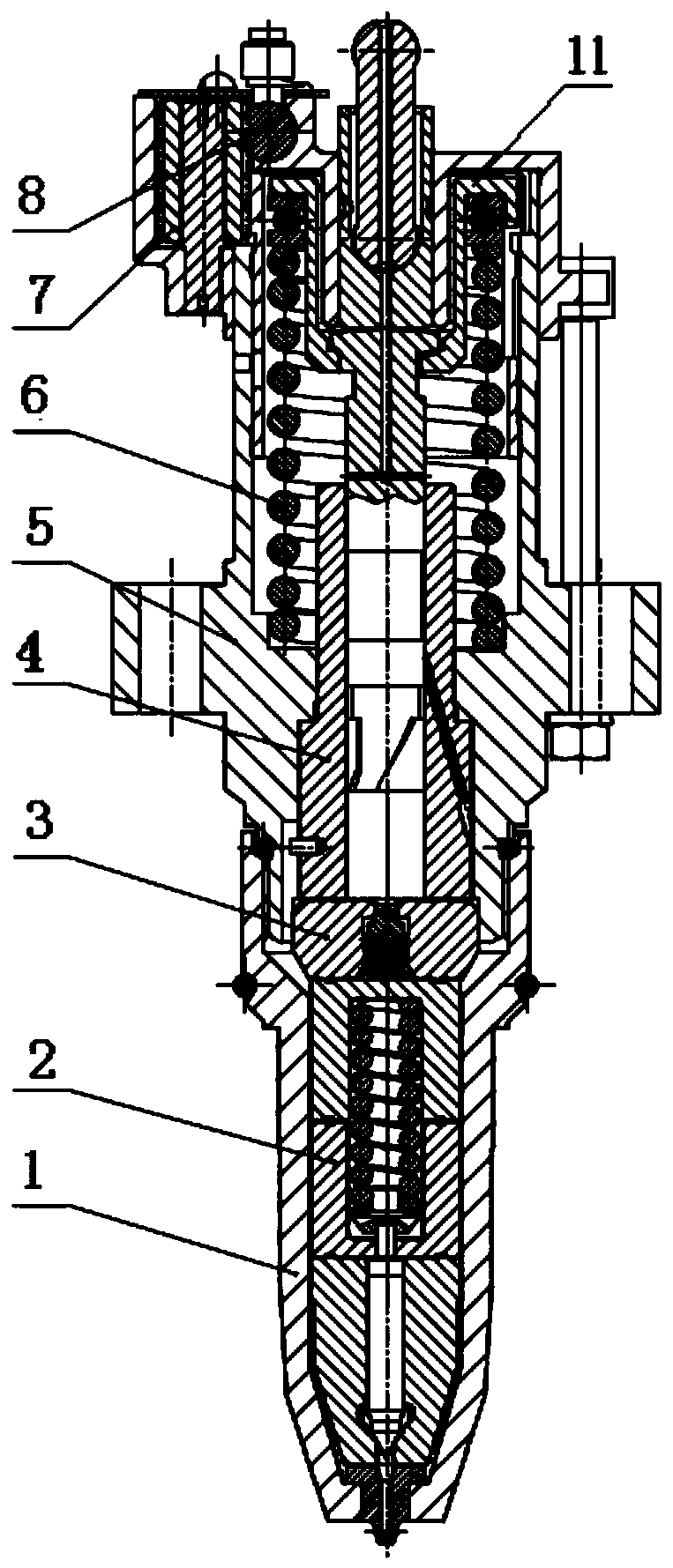

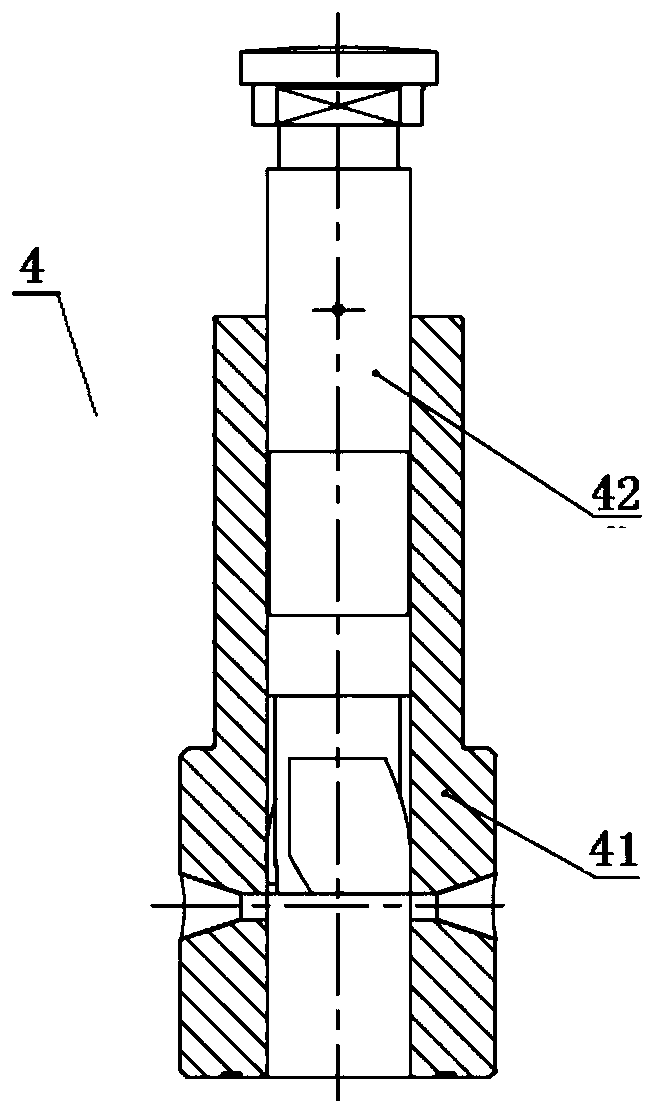

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see Figure 1 to Figure 5 The fuel injector that integrates the electronically controlled unit pump is shown, including the pump body 5 of the electronically controlled unit pump, the plunger couple 4 arranged in the pump body, and the column set outside the upper part of the plunger couple. Plug spring 6, its prominent substantive features are: the inner wall of the upper end of a nozzle locking sleeve 1 is threadedly connected with the outer wall of the lower end of the pump body 5, and the inner wall of the nozzle locking sleeve 1 is sequentially connected from bottom to top. A nozzle assembly 2 and an oil outlet valve assembly 3 are provided, and the upper end of the oil outlet valve assembly is in close contact with the lower end of the plunger couple 4; a gear 7, a rack 8 and a gear 8 are arranged on the upper part of the pump body 5 Driving rod 11, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com