Pre-sand discharge structure of rotary air compressor

An air compressor and rotor-type technology, which is applied in the field of air compressors, can solve the problems that the air filter cannot meet the requirements of filtering air and is easily damaged, so as to improve the screening efficiency and avoid the effect of less air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

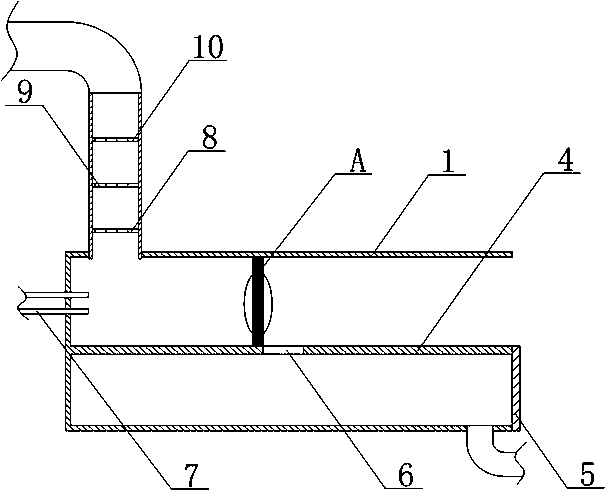

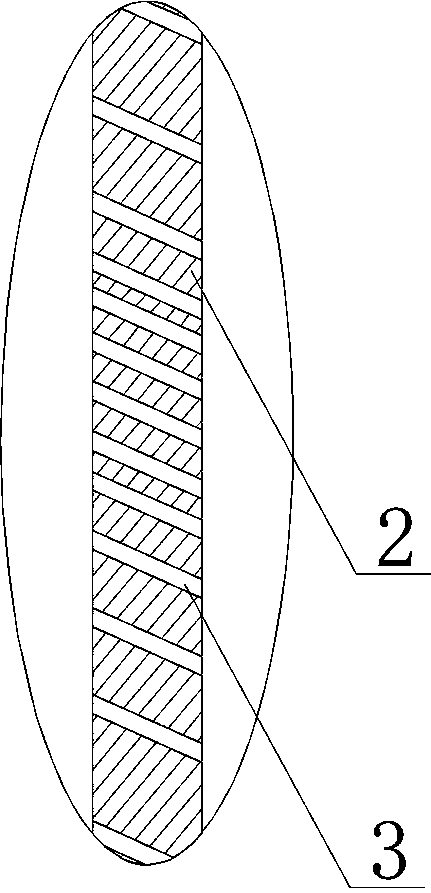

[0028] Such as figure 1 with figure 2 As shown, the present invention is a pre-sand discharge structure of a rotor type air compressor, including a housing 1, one end of the housing 1 is a closed end, and the other end is an open end, and the top of the housing 1 is equipped with an exhaust pipe close to the closed end. The exhaust pipe is close to one end of the housing 1 to the other end, and the first grid 8, the second grid 9, the third grid 10 are arranged in the exhaust pipe in sequence, the first grid 8, the second grid 9, the first grid Cotton layers are all laid on the three grids 10, wherein, the cotton layer on the first grid 8 is filled with desiccant, the cotton layer on the second grid 9 is filled with solids that absorb acid gas, and the third grid The cotton layer on 10 is filled with solids that absorb toluene or xylene, and the closed end of the housing 1 is provided with a partition 4 parallel to the horizontal plane and a flushing pipe 7, the flushing pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com