Speed reducer

A technology of reducer and input shaft, which is applied in the direction of portable lifting device, transmission device parts, gear transmission device, etc., can solve the problems of low transmission efficiency, single function, low precision, etc., and achieve obvious work efficiency, simple operation and excellent structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

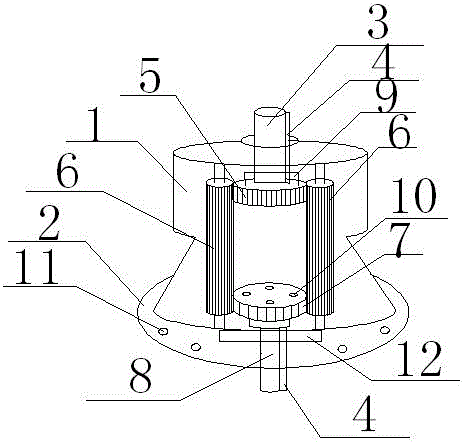

[0013] Such as figure 1 As shown, a reducer, the reducer includes a reducer housing 1 and an output end cover 2; the top of the reducer housing 1 is provided with an input shaft 3; the bottom of the input shaft 3 is connected to the main gear 5 through a slot 4 ; The two sides of the main gear 5 are provided with a driven gear 6; the bottom of the driven gear 6 is meshed with the output gear 7 through the gear teeth; the output shaft 8 is set in the middle of the output end cover 2; the output shaft 8 It is connected to the output gear 7 through the card slot 4.

[0014] The intersecting part of the main gear 5 and the input shaft 3 is provided with a radiator 9, and the radiator 9 is made of an aluminum alloy material. When the input shaft 3 works, the power is relatively large and a large amount of heat will be generated. In order to avoid the generated heat Affecting the work of the reducer, the heat must be dissipated, and the aluminum alloy material not only has a good h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com