Anti-explosion LED light source module

A technology of LED light source and LED light strip, applied in the direction of light source, electric light source, light source fixing, etc., can solve the problems of difficulty in adapting to harsh working environment, high energy consumption of explosion-proof lamps, poor explosion-proof performance, etc., and achieve electro-optical conversion efficiency. High, perfect safety protection, improve the effect of explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

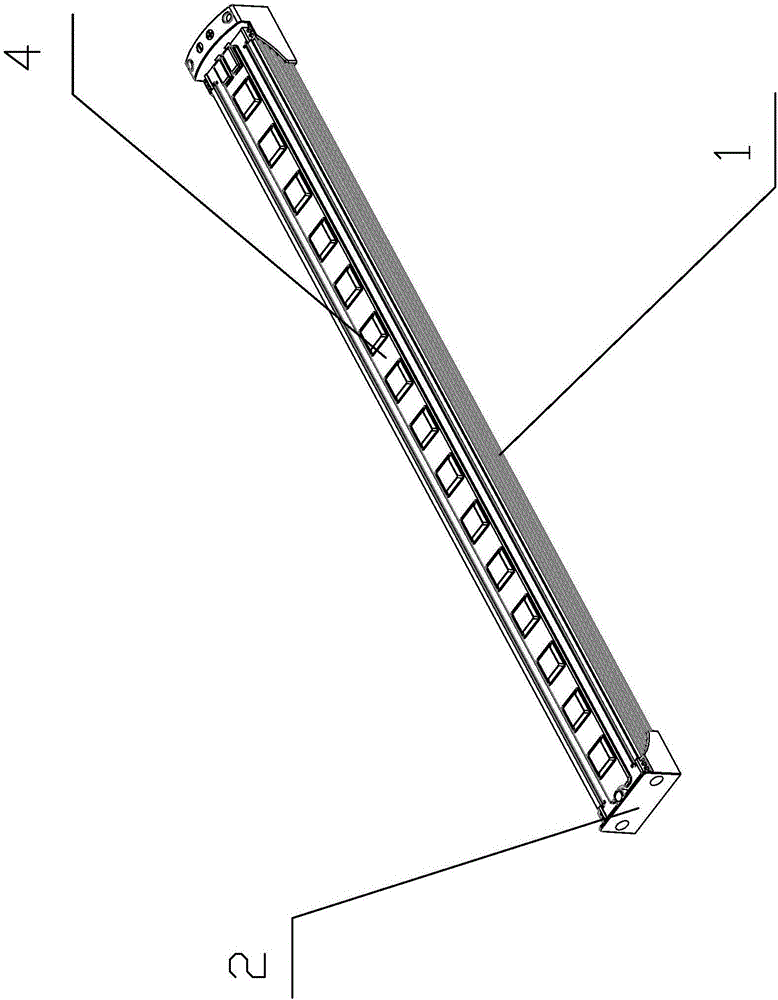

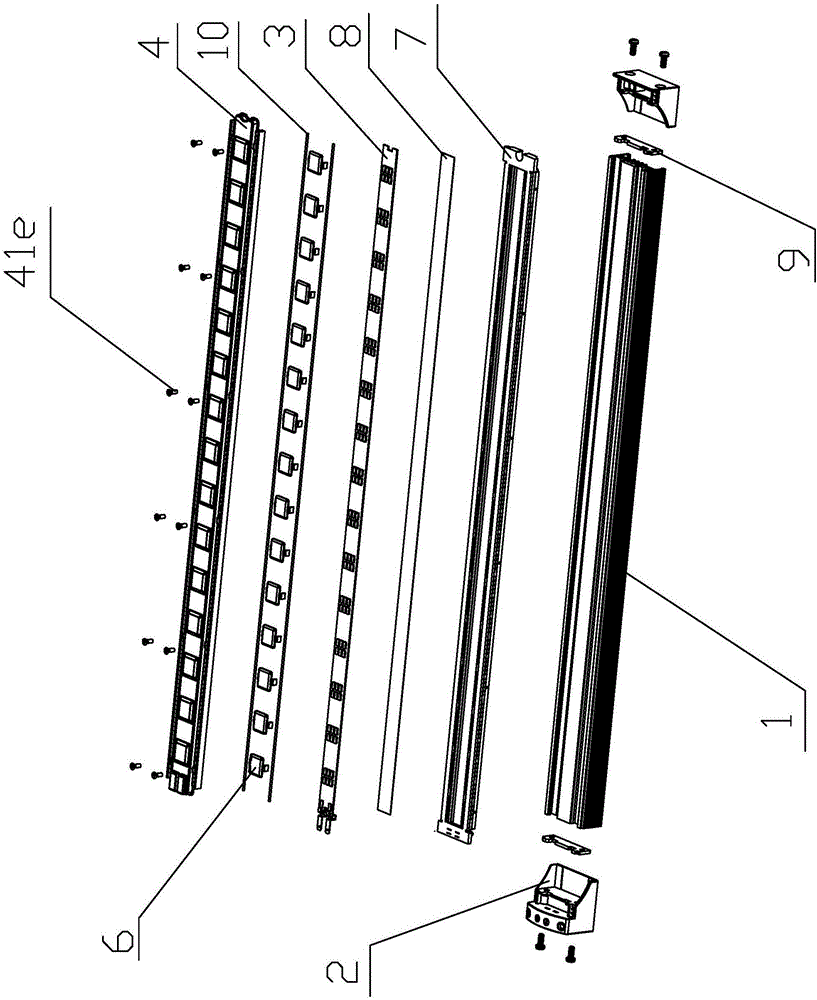

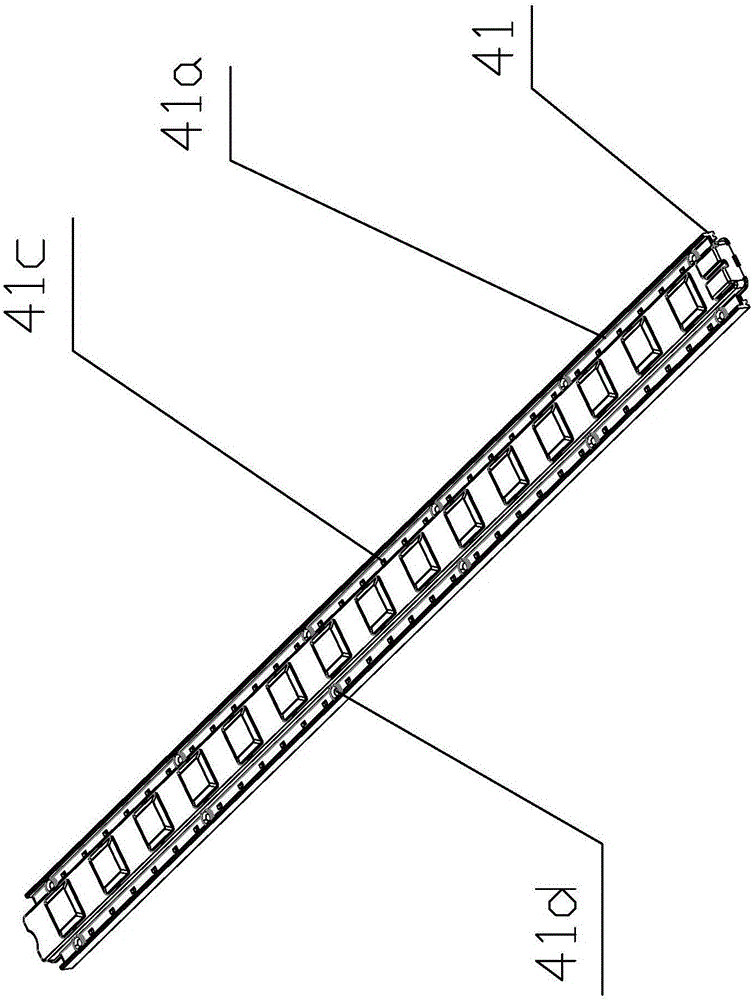

[0030] Embodiments of the explosion-proof LED light source module of the present invention are as follows: Figures 1 to 8 As shown: it includes a lamp body, a light-emitting component fixed on the lamp body, and a lamp holder 2 fixed to the lamp body. The light-emitting component includes a light-emitting part and a lampshade 4 that covers the light-emitting part. The LED light strip 3 includes a substrate 31 and LED particles 32 distributed on the substrate 31. The lamp body includes a heat sink 1. The heat sink 1 is made of metal material and is made by extrusion or molding. The heat sink 1 It includes a heat dissipation table 11 for attaching and fixing the LED light strip 3 and installation grooves 12 on both sides of the heat dissipation table 11. The back of the LED light strip 3 is attached to the heat dissipation table 11 of the heat sink 1, and the lampshade 4 is inserted into the In the installation grooves 12 on both sides of the heat dissipation table 11, there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com