Sampling Equipment for Solid Hard Capsules

A hard capsule and solid technology, applied in the direction of sampling devices, etc., can solve the problems of uniformity of solid drugs, high labor intensity, long maintenance time, etc., achieve the effect of convenient and fast sampling operation, reduce labor intensity, and save maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

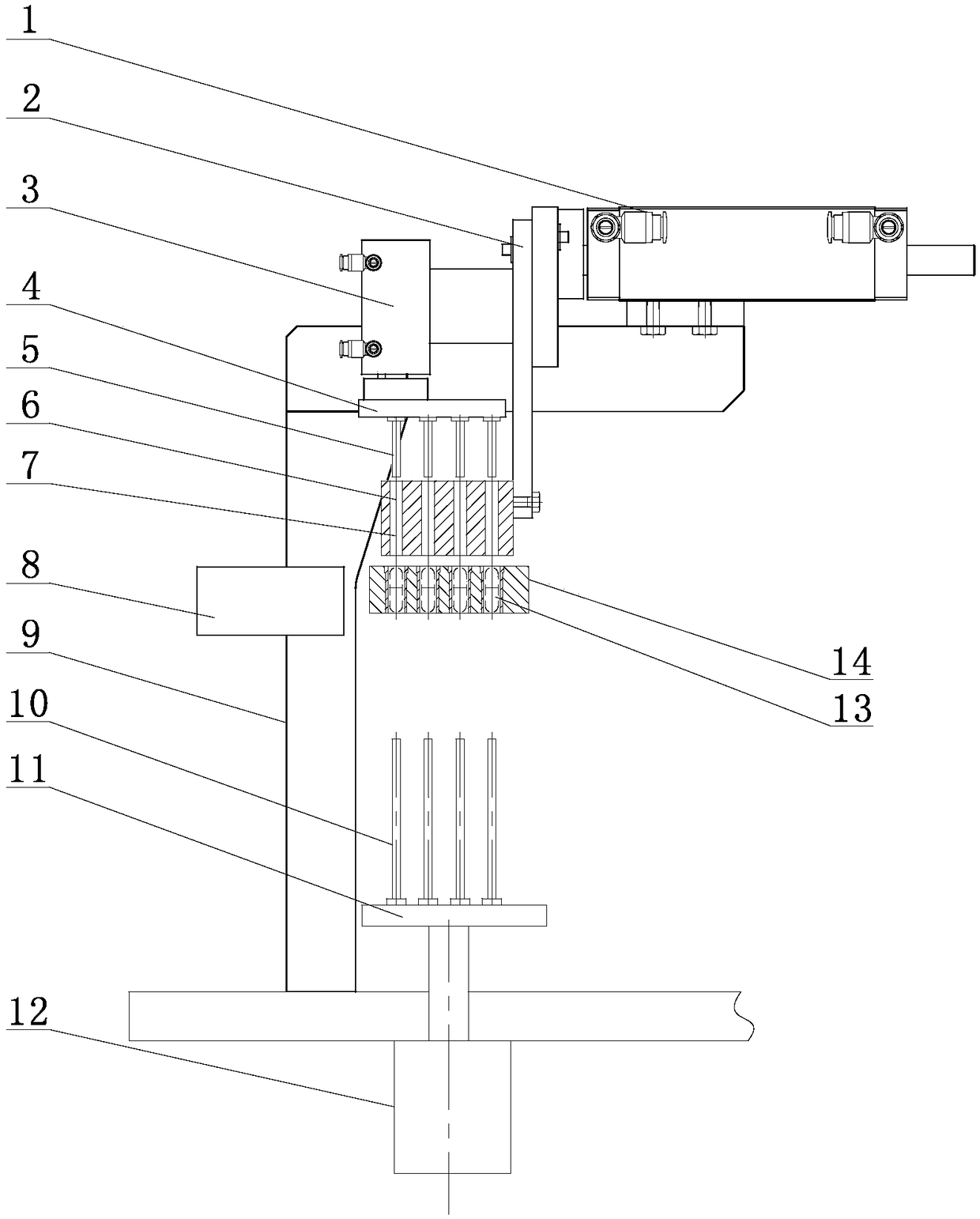

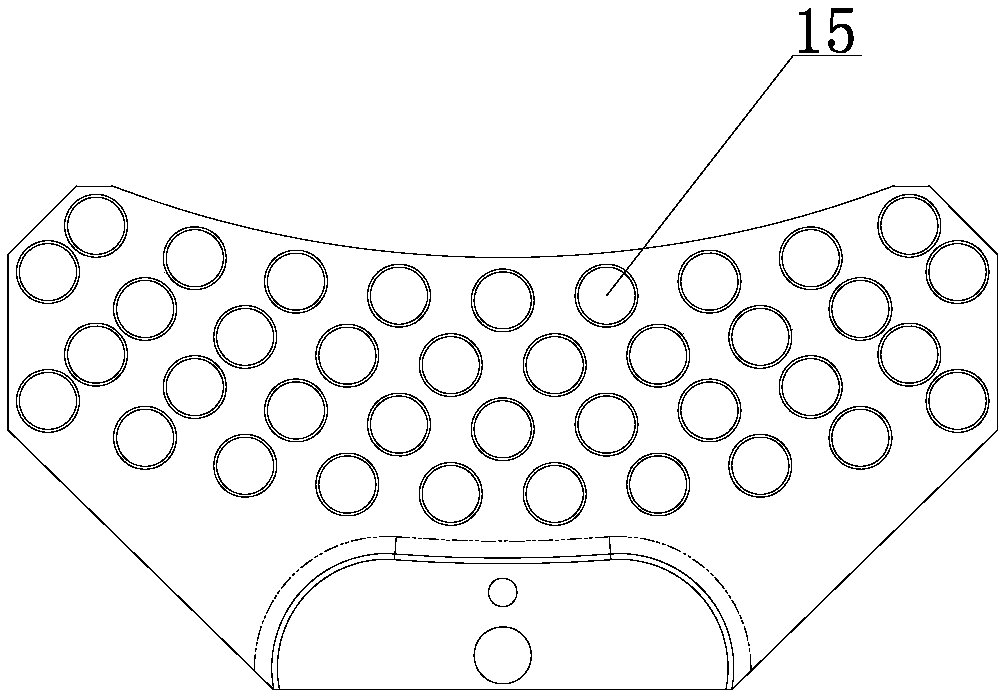

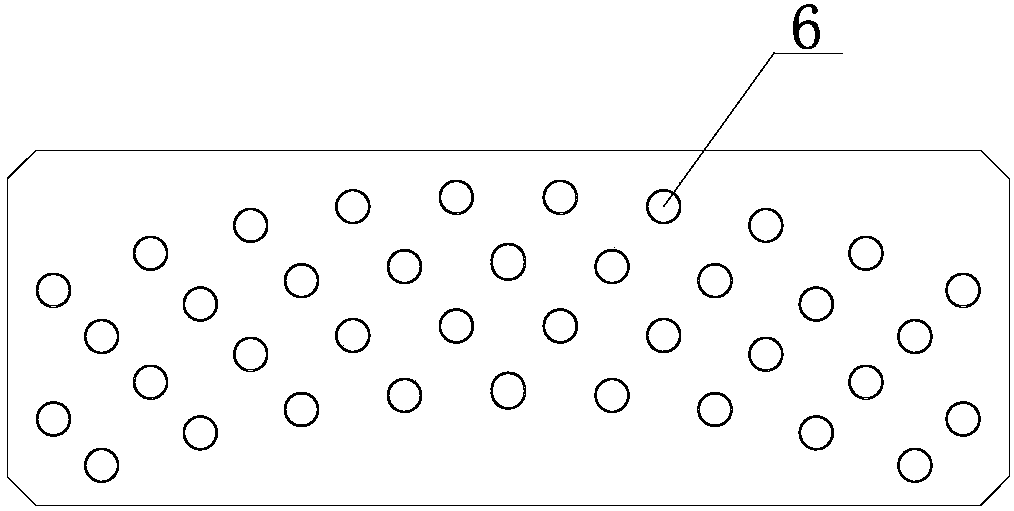

[0038] Such as figure 1 As shown, a horizontal translation device is installed on the top of the frame 9 of the sampling equipment of the solid hard capsule according to the present invention, and the front part of the horizontal translation device is fixed to the mounting plate 2, and the top of the front plate surface of the mounting plate 2 is equipped with a lifting device, and the bottom is installed A transfer block 7, the lifting device can simultaneously drive the N 1 The root discharge ejector rod 5 moves up and down, and N is set on the transfer block 7. 2 a via 6 (such as image 3 shown), the middle part of the frame 9 is equipped with a sampling box 8, and the sampling box 8 is provided with N 3 Two mutually isolated cavities 16 are provided with mounting lugs 17 on both sides of the sampling box 8 at the same time, and a bayonet 18 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com