Hall sensor magnetic flux test structure

A Hall sensor and test structure technology, applied in the direction of measuring magnetic variables, instruments, measuring devices, etc., can solve the problems that affect the test accuracy and results, and there is no Hall sensor magnetic field strength specification, etc., to achieve the improvement of test accuracy and increase Trigger rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

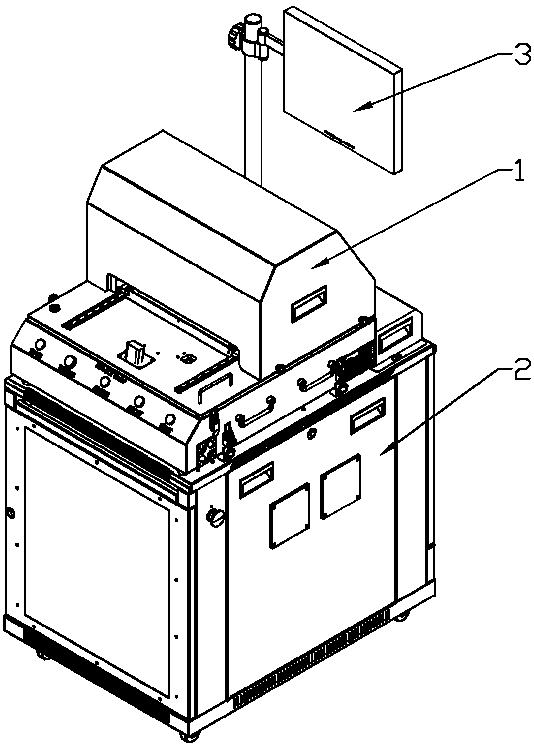

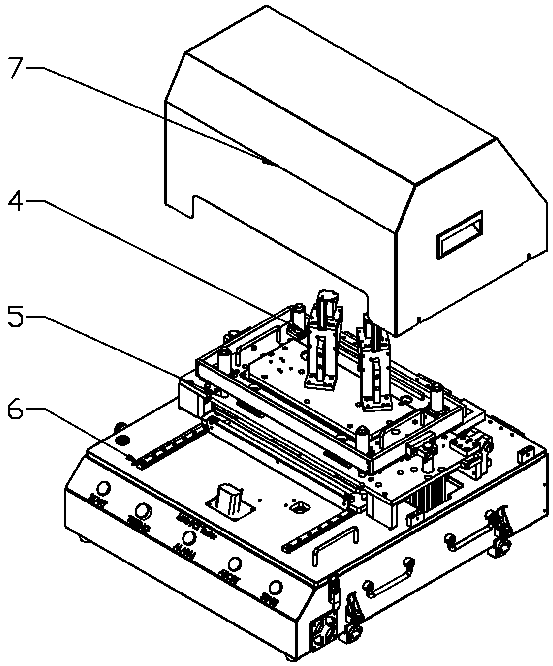

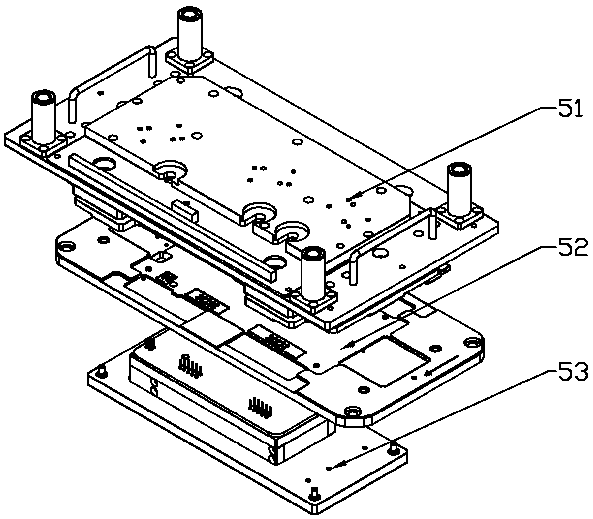

[0021] Such as Figure 1 to Figure 6 As shown, in this embodiment, the present invention includes a function test module 1, a split test cabinet 2 and a touch control system 3, and the function test module 1 and the touch control system 3 are installed in the split On the counter top of the test cabinet 2, the touch control system 3 is located on one side of the functional test module 1, and the inside of the split test cabinet 2 is provided with a circuit board and a power supply, and the functional test module 1, The split test cabinet 2 and the touch control system 3 are electrically connected to each other, the functional test module 1, the split test cabinet 2 and the touch control system 3 adopt a separate design, and Non-integrated design, and their shells are covered with steel or sheet metal cold plates or other magnetic field shielding materials to reduce the interference of the magnetic field generated by the invention itself on the Hall sensor. This is the first-le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com