Two-element self-breaking liquid and gas cracked rock pipe

A technology of cracking rock pipe and liquid gas is applied in the field of two-element self-breaking liquid-gas cracking rock pipe, which can solve the problems of affecting the effect of rock cracking, insufficient instantaneous pressure under high pressure, causing danger, etc., so as to reduce equipment use costs and failure rates, Improve work efficiency and improve the effect of blasting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

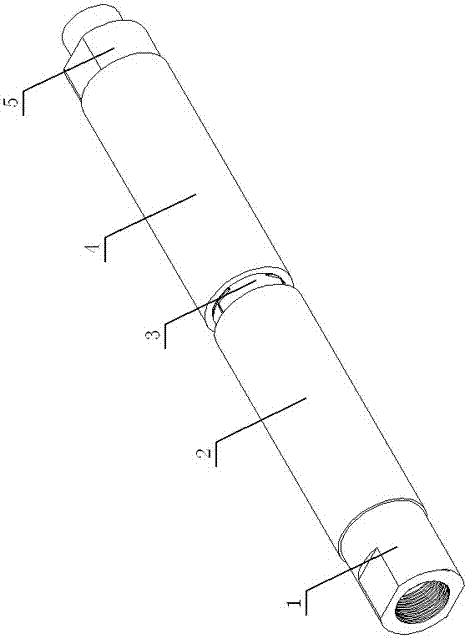

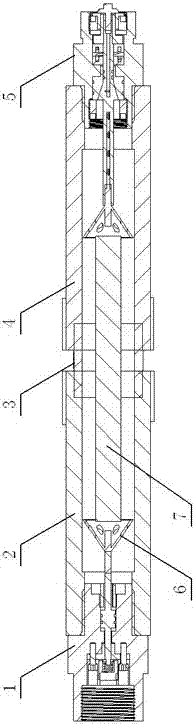

[0031] See attached Figure 1-8 , The rock cracking pipe disclosed in the present invention is a liquid-gas blasting pipe, which can be widely used in fields requiring safe blasting, and has high safety, strong blasting force, simple operation, high efficiency and low use cost.

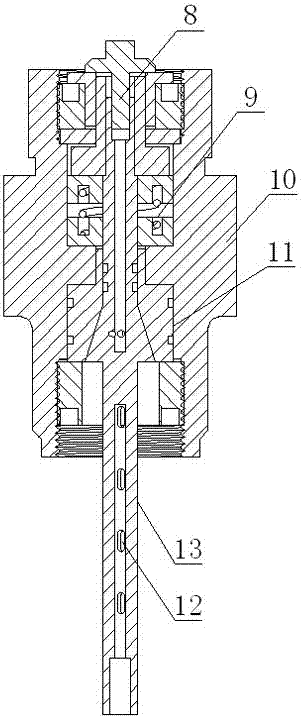

[0032] The binary self-cutting liquid gas-cracking rock pipe disclosed by the present invention includes A\B unit pipe bodies, heat source pipes are arranged in the pipe bodies, and liquid-filled electrode heads and electrode tail seats are respectively installed at both ends of the pipe body. The tailstock is equipped with a K cathode electrode screw. The liquid-filled electrode head is connected to one end of the tube body of unit A through threads, the tube body A and tube B are connected through an overpressure energy release device, the tailstock of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com