Intelligent continuous caster control platform

A technology of intelligent control and continuous casting machine, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve the problem that cloud computing technology has not been practically applied, subsystems have not been reasonably and effectively integrated, and constraints on production technology and production Improve the quality of process products and other issues to achieve the effect of solving optimization and fault diagnosis problems, realizing data sharing and service support, and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] This embodiment supervises the development process of each subsystem according to Project Portfolio Management (Project Portfolio Management, PPM) and Capability Maturity Model (Capability Maturity Model for Software, CMM), and adopts an integration method based on the bridge mode to integrate each subsystem of the project Integrate to optimize the overall benefit of the system.

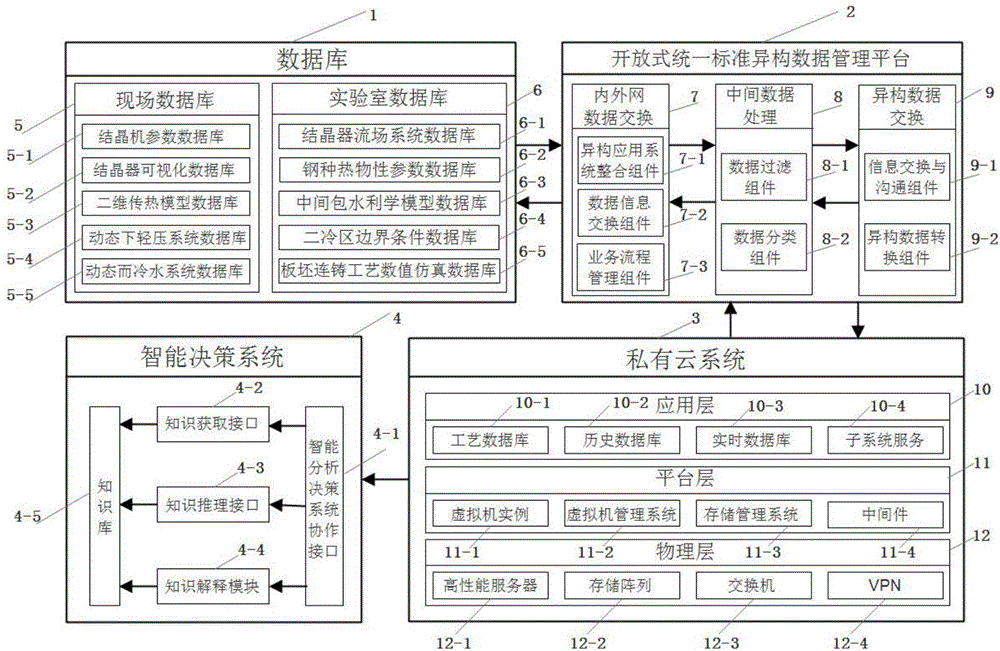

[0020] see figure 1 , an intelligent control platform for continuous casting machines, including a database 1, the database 1 is bidirectionally connected with an open unified standard heterogeneous data management platform 2, the open unified standard heterogeneous data management platform 2 is bidirectionally connected with a private cloud system 3, and the private cloud The output of system 3 is connected with the input of intelligent analysis and decision-making ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com