Automatic conveying device for beverages in vending machine

An automatic conveying device and vending machine technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problem of affecting the consumption experience, time-consuming and labor-intensive, beverages are taken away by consumers before they are refrigerated for a certain period of time and other issues to achieve the effect of improving consumer experience, smooth and efficient delivery process, and increasing efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

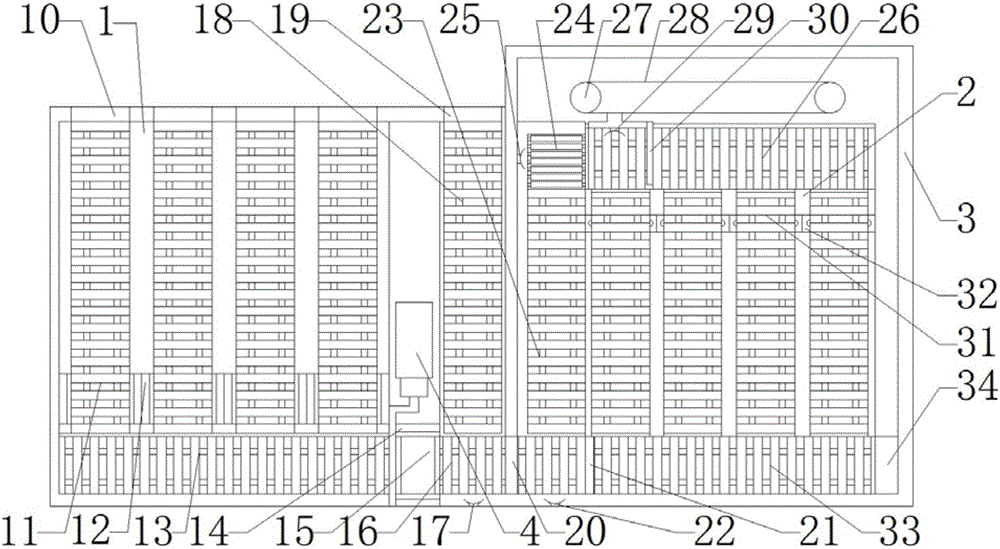

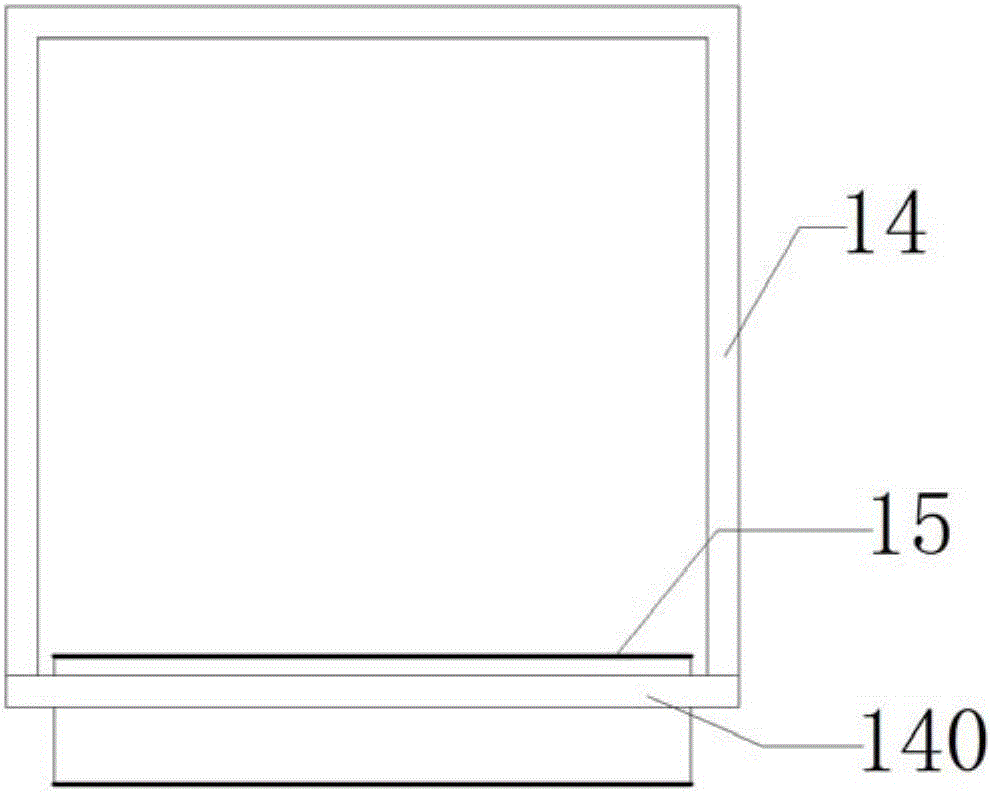

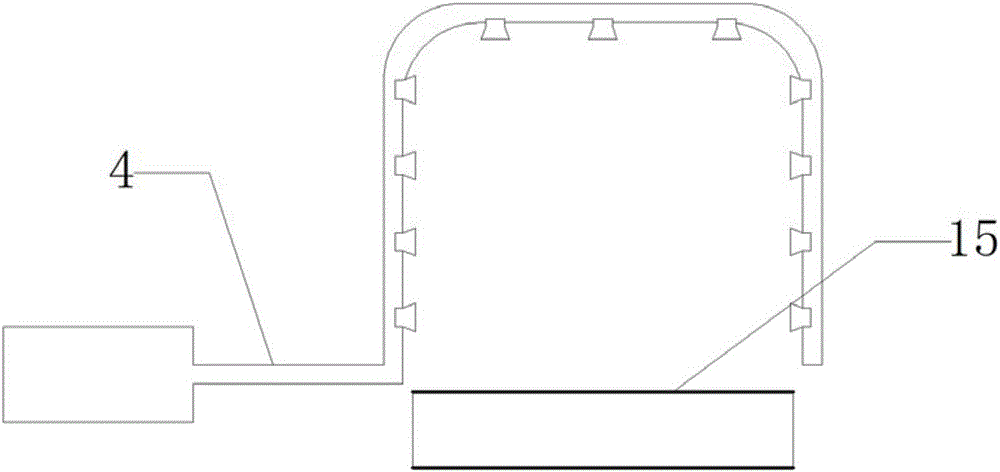

[0045] see figure 1 , figure 2 and image 3 , an automatic beverage delivery device in a vending machine of this embodiment, including a storage mechanism, an inspection and cleaning mechanism, a cold storage input mechanism, a refrigerated delivery mechanism and a complete machine control system.

[0046] The whole machine control system includes a purchase information input panel and a beverage transportation control circuit. The purchase information input panel is arranged on the outer surface of the vending machine for consumers to input and select beverage type and quantity information; the beverage transportation control circuit is used to Select information to control the work of the beverage automatic delivery device in the vending machine.

[0047] The refrigerated delivery mechanism includes a refrigerated conveyor belt 31, a vacancy sensor 32, a cold storage partition 2, a delivery conveyor belt 33, and an induction delivery door 34. The delivery conveyor belt 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com