Oil and gas pipeline defect detecting and monitoring experimental platform

A defect detection and experimental platform technology, which is applied in the field of oil and gas safety engineering, can solve problems such as large footprint, waste of resources, pipeline leakage, etc., and achieve the effects of reduced footprint, improved reliability, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

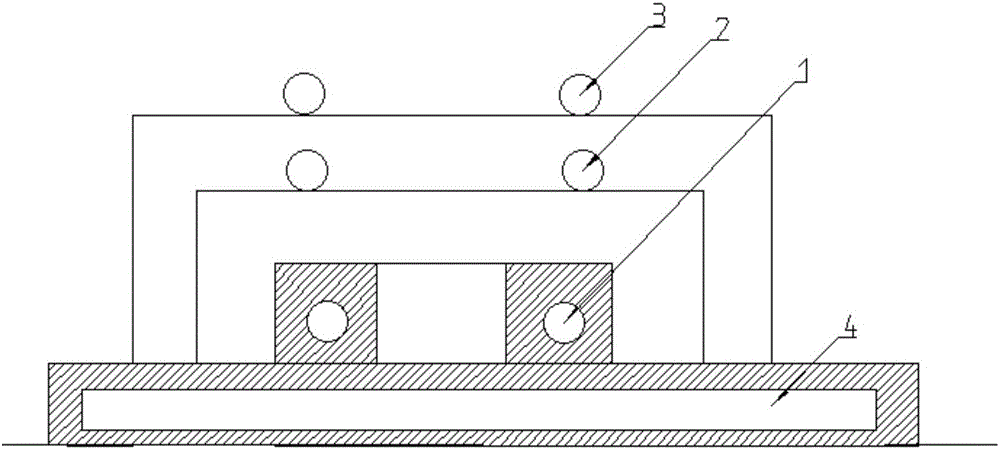

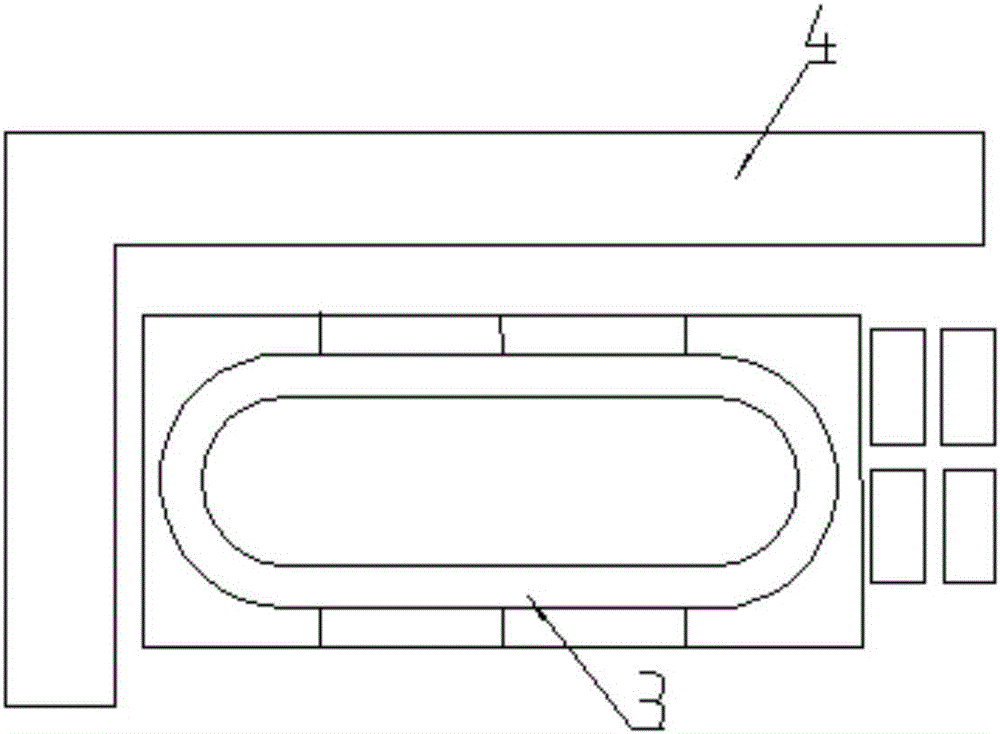

[0034] From figure 1 , 2 It can be seen that an oil and gas pipeline defect detection and monitoring experiment platform includes an oil and gas pipeline detection experiment platform. A three-layer pipeline support mechanism is arranged on the pipeline inspection experiment platform. The first pipeline layer 1, the second pipeline layer 2, and the third pipeline layer 3 are also provided with an "L"-shaped pipeline layer 4 beside the three-layer pipeline support mechanism. Both the first pipeline layer 1 and the "L"-shaped pipeline layer 4 are Covered with soil, the inlet ends of the first pipeline layer 1, the second pipeline layer 2, the third pipeline layer 3, and the "L"-shaped pipeline layer 4 are all communicated with the air outlet of the air compressor.

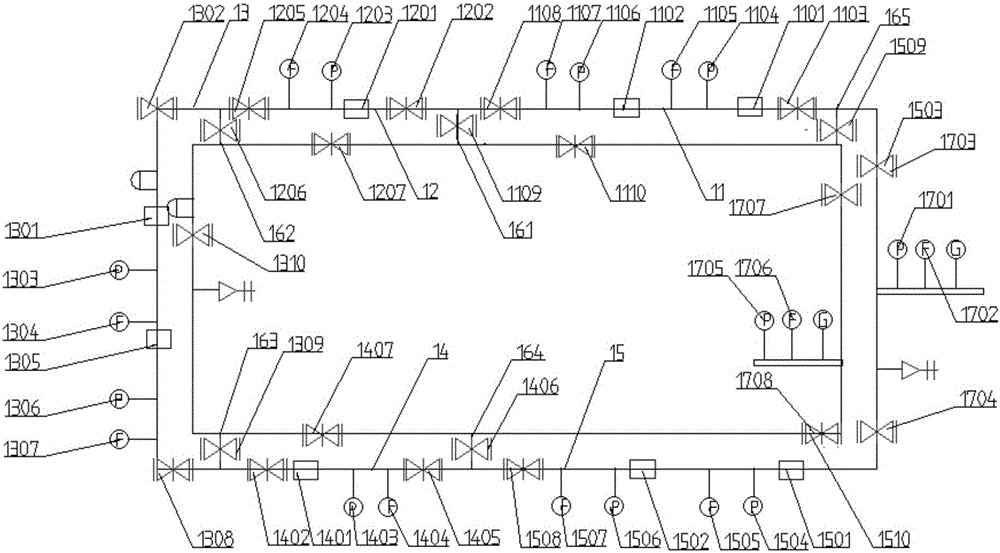

[0035] image 3 It can be seen th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com