Formation method of lithium ion battery

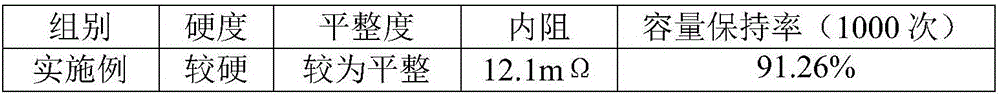

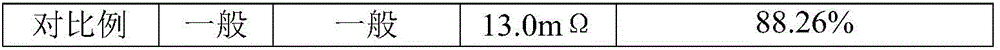

A technology of lithium-ion batteries and formation methods, which is applied in the field of formation of lithium-ion batteries, can solve problems such as hindering electrode reactions, increasing internal resistance of batteries, and affecting battery performance, so as to reduce internal resistance of batteries and improve flatness , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

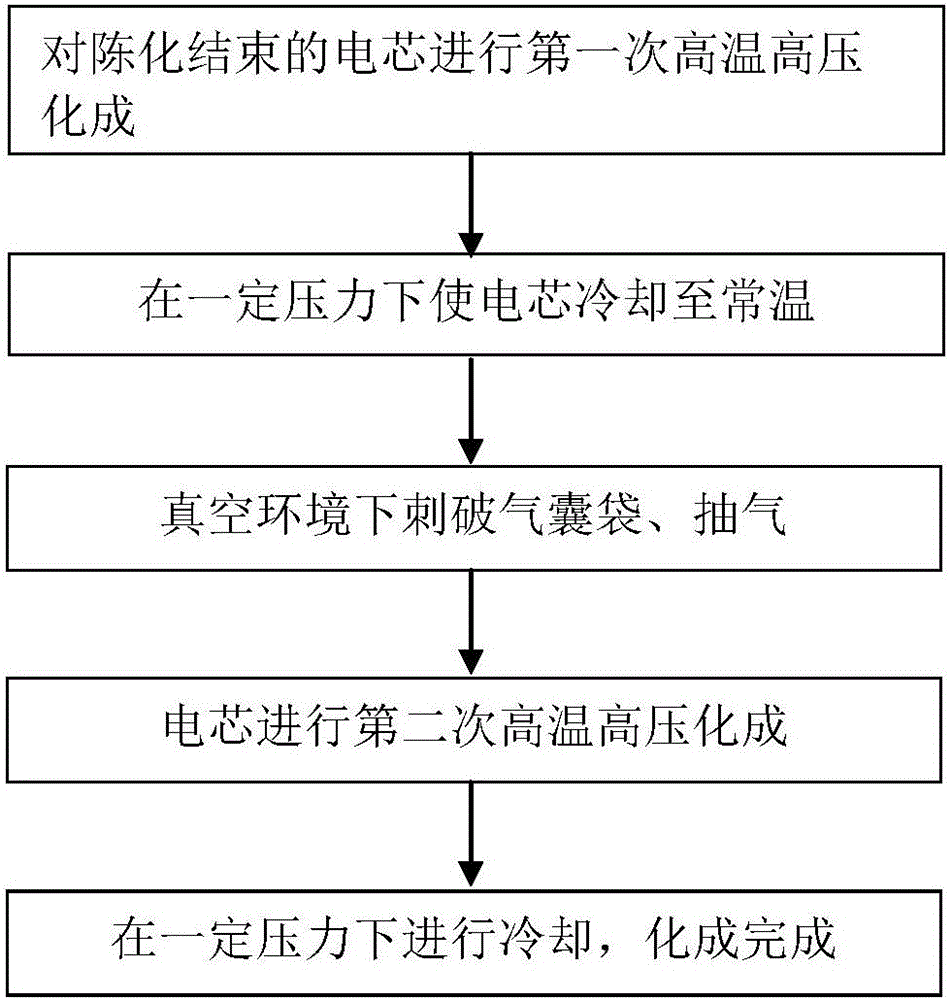

[0022] The basic idea of the method of the present invention is: put the aging cell into high-temperature pressurized forming equipment for charging, then cool the cell at room temperature under a certain pressure, and put the cell down to normal temperature into a vacuum environment , puncture the airbag bag, pump air, and then seal it. The sealed cell is put into the high-temperature pressurized forming equipment for charging again, and finally it is cooled at room temperature under a certain pressure until the cell drops to room temperature and the formation is completed. .

[0023] The above is the core idea of the present invention. The technical solutions of the embodiments of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com