Air chamber frequency selection surface structure

A frequency selective surface, air cavity technology, applied in electrical components, circuits, resonators, etc., can solve the problems of small frequency response curve slope, few controllable parameters, poor polarization stability, etc., to achieve rapid prototyping, wide application, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

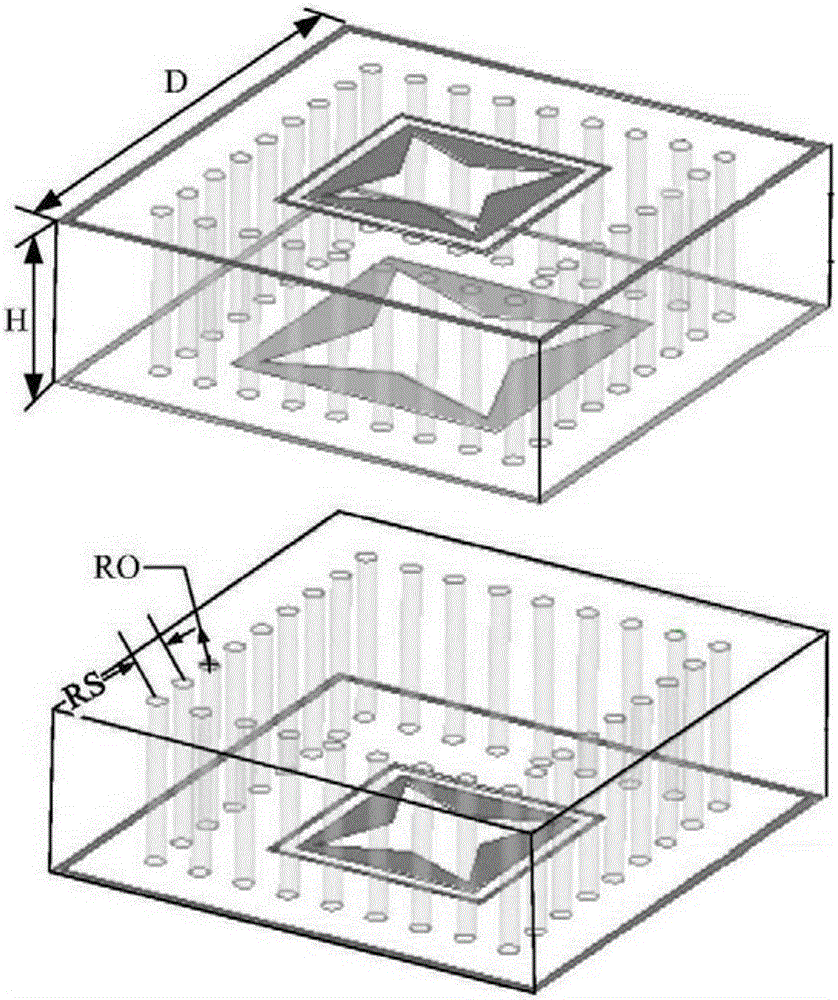

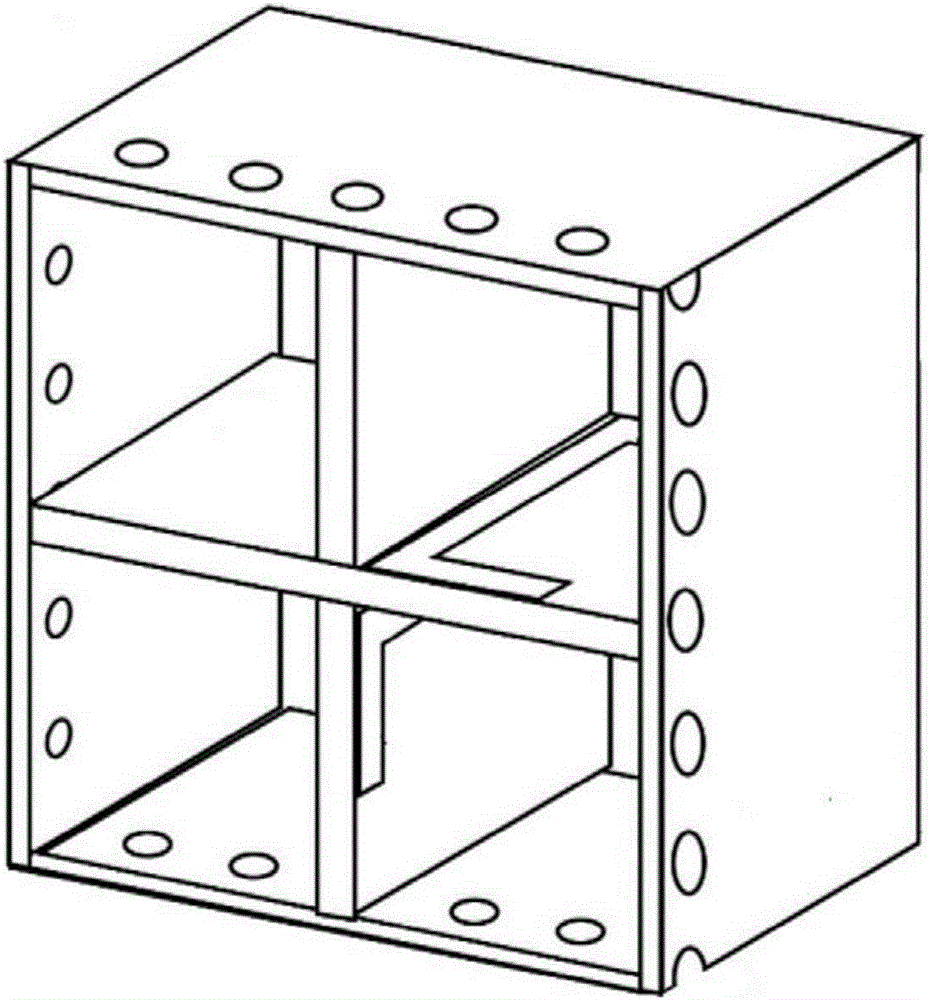

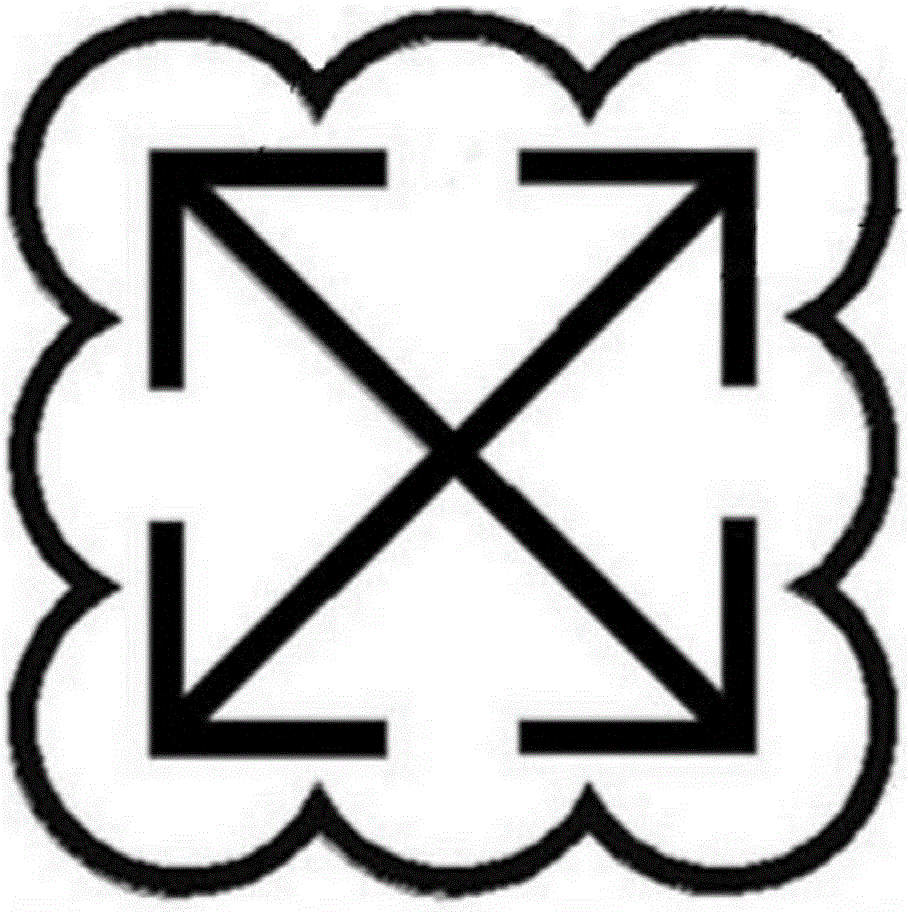

[0036] Such as Figure 4 ~ Figure 6 As shown, the frequency selective surface structure of the air cavity in this embodiment is composed of M*N identical periodic units, and each periodic unit is a cuboid structure. The front and back of the cuboid structure have a groove line, and the front groove line It is the first groove line 1, and the groove line on the opposite side is the second groove line 2. The first groove line 8 and the second groove line 9 are rectangular groove lines with a length of L and a width of W. The middle of the cuboid structure is an air cavity resonator 3, the inner and outer surfaces of the air cavity resonator 3 are surrounded by metal; wherein, M>10, N>10, due to the large number of periodic units, only shown in the figure of this embodiment The number of periodic units of 2*2.

[0037]The air cavity resonator 3 is formed by 3D printing, so it can be quickly formed, the processing is quite easy, and the precision is high; the metal is covered on ...

Embodiment 2

[0046] The main features of this embodiment are: as Figure 8 As shown, the air cavity frequency selective surface structure of the present embodiment is used as a three-frequency air cavity frequency selective surface structure, and the first groove line 1 on the front side of the cuboid structure is along the positive direction of the X axis relative to the geometric center point of the cuboid structure ( +X axis) offset distance S, and rotate angle θ to the right relative to the Y axis; the second groove line 2 on the reverse side of the cuboid structure is along the opposite direction of the X axis (-X axis) relative to the geometric center point of the cuboid structure The distance S is offset, and the angle θ is rotated to the right relative to the Y axis, that is to say, the first groove line 1 and the second groove line 2 are offset in opposite directions but rotate in the same direction. All the other are with embodiment 1.

[0047] The electromagnetic simulation cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com