Low-speed juicing system with overload protection function and overload protection method

A technology of overload protection and fast pressing, which is applied in the direction of household machinery, household appliances, kitchen utensils, etc. for filtering food to achieve the effect of avoiding errors, compact structure, good practicability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0029] For the sake of illustration, the width, length, thickness, etc. of some components in the schematic diagrams are sometimes exaggerated.

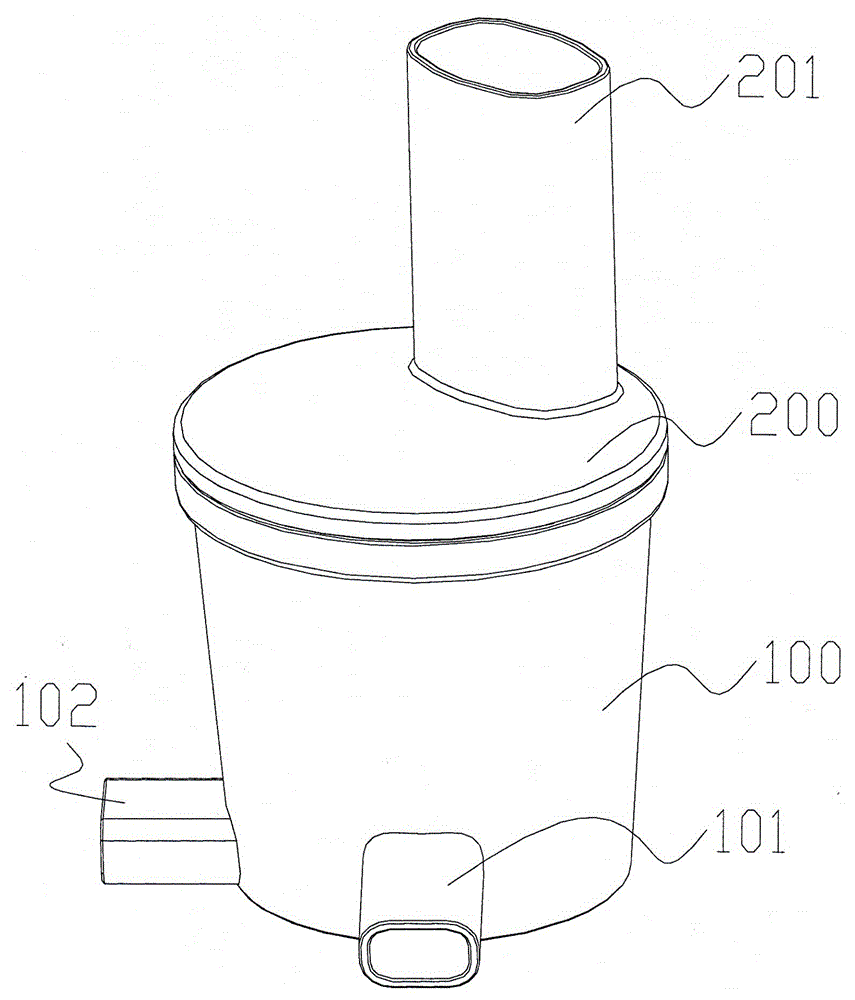

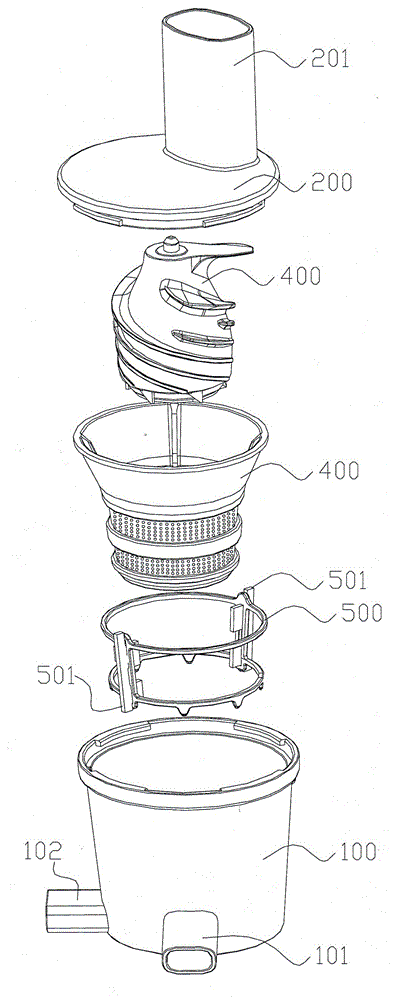

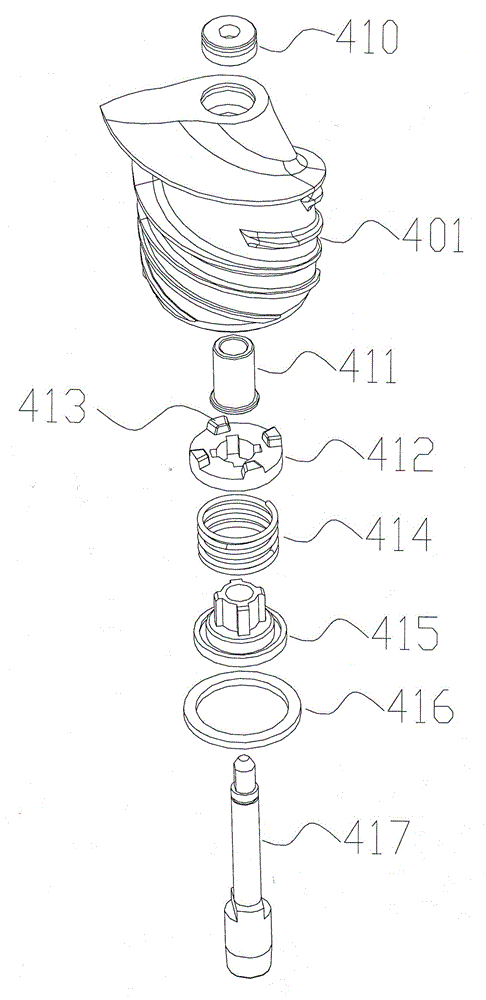

[0030] according to Figure 1 to Figure 6 As shown, the juice extraction assembly of the slow juice extraction system in the embodiment of the present invention includes the following parts: a container 100 with a juice extraction space inside and a juice outlet 101 and a slag outlet 102 at both ends of the outside; A container cover 200 with a feeding port 201, a filter screen 300 located inside the container 100 to separate the juice from the slag juice mixture; a screw assembly 400 located inside the filter screen 300 for squeezing fruits and vegetables; usually also has The annular scraper frame 500 located outside the filter screen 300 has several soft rubber scrapers 501 distributed around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com