Biomass vertical ring-die pelletizing mechanism

A technology of ring die granulation and biomass, which is applied in the direction of mold extrusion granulation, etc., can solve the problems of equipment not working continuously, high cost, time-consuming and labor-intensive, etc., and achieve compact structure, high precision, and not easy to damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the original components of the traditional known structure are not described or shown in the figure, and the auxiliary connection mechanism and driving device matched with the mechanism are the same as the traditional mechanism, and will not be described in detail here.

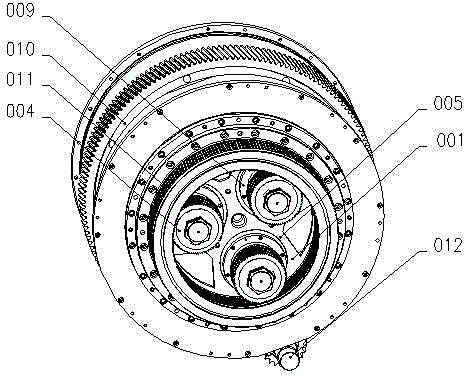

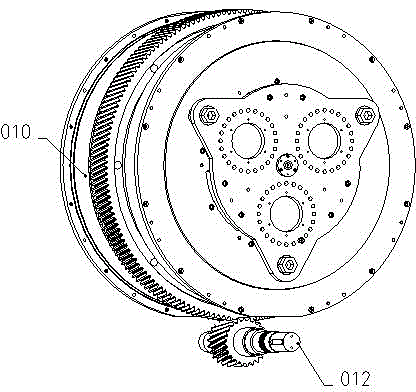

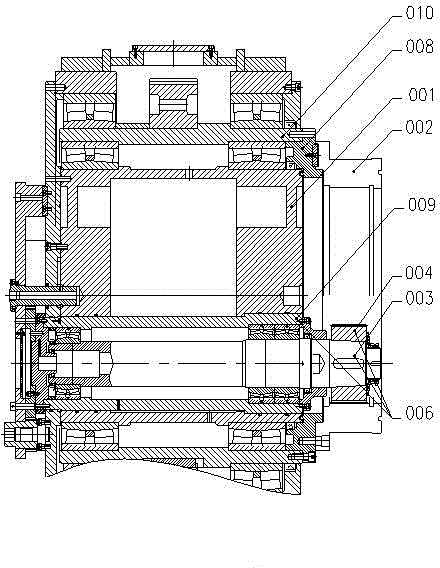

[0022] Such as Figure 1-3 As shown, the biomass vertical ring die granulation mechanism disclosed in this embodiment includes a structural main body, which is composed of a pressing chamber 005, a pressing roller assembly 006 and a driving mechanism (not shown in the figure). The pressure roller assembly 006 is composed of a roller shaft 003, an eccentric sleeve 009 and a pressure roller 004. The driving mechanism is at least composed of a motor and a transmission mechanism. A ring die 002 and a transition flange 008 are arranged on one side of the main body of the structure, and the The independent space between the ring die 002 and the pressing roller 004 constitutes the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com