Automatic balancing hoop bending machine capable of achieving arc wire feeding

An automatic balancing and hoop bending machine technology, applied in the field of hoop bending machines, can solve the problems of high cost, cumbersome operation, complex structure, etc., and achieve the effects of low production cost, reduced labor, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

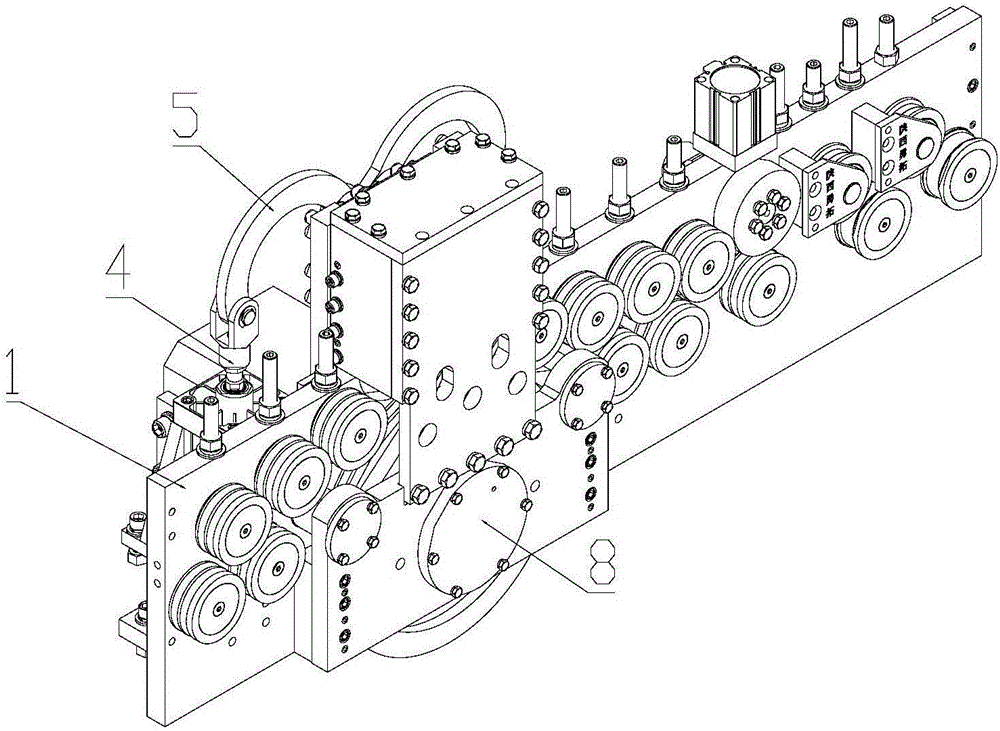

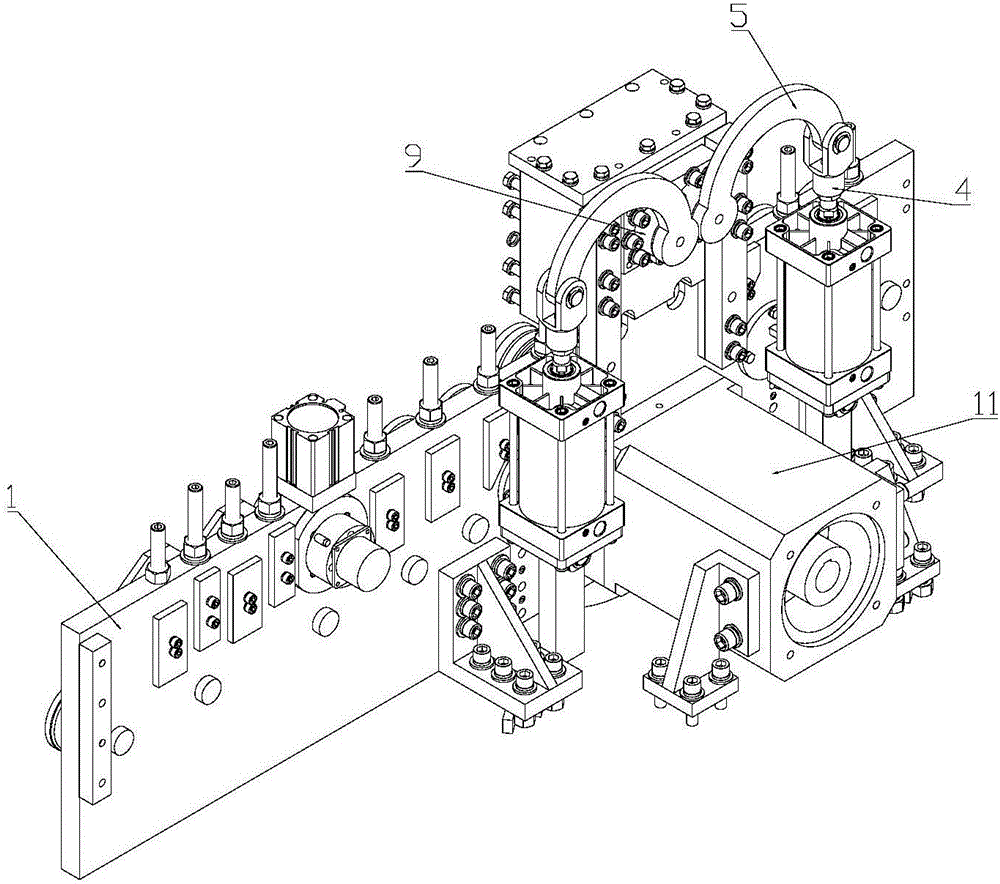

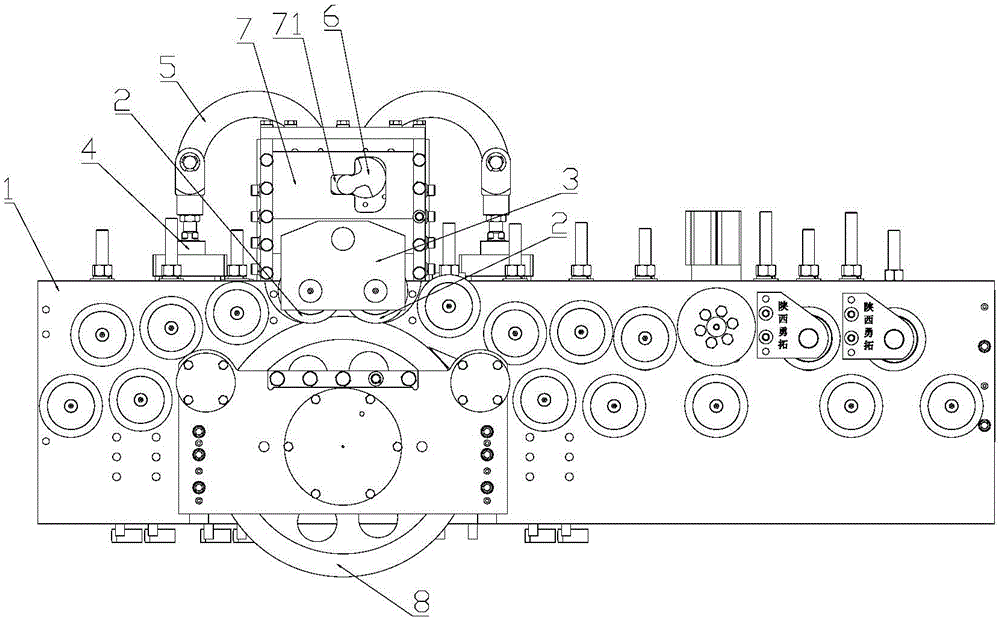

[0041] Such as Figure 1 to Figure 3 As shown, an arc-shaped wire feeding automatic balance hoop bending machine provided by the present invention includes a frame 1 and a traction mechanism arranged on the frame 1. The traction mechanism includes a main driving wheel 8 and is located above the main driving wheel 8. At least one pressure roller group, each pressure roller group is composed of at least two pressure rollers 2 arranged side by side along the feeding direction of the steel bar 12; the outer edge of the main driving wheel 8 is provided with a slot 10, the at least two A pressure wheel 2 is pressed on the steel bar 12 in the socket 10 of the main driving wheel 8; one end of the main driving wheel 8 is connected to a rotating power source 11, and the rotating power source 11 is supported on the frame 1; at least two of the pressing wheels 2 It is arranged on the depressing mechanism for adjusting its position, and the depressing mechanism is arranged on the frame 1; ...

Embodiment 2

[0044] On the basis of Embodiment 1, the number of the eccentric shaft pressing mechanism can be selected according to actual needs. Of course, the present invention is not limited to the cases enumerated in this embodiment.

[0045] If only one steel bar 12 is conveyed, the eccentric shaft type depressing mechanism can be formed into one group. At this time, a caulking groove 10 is arranged on the outer edge of the main driving wheel 8, and the at least two pressing wheels 2 They are arranged side by side along the feeding direction of the reinforcing bars 12 and pressed against the reinforcing bars 12 in the said one embedding groove 10 . When conveying a steel bar 12 of uneven thickness, the pressure roller adjustment plate 3 will rotate a certain angle to the pressure roller that cannot be pressed under the pressure of the eccentric shaft type pressing mechanism, and automatically adjust the balance state so that the two pressure rollers 2 can be compressed, and the reinf...

Embodiment 3

[0048] On the basis of Example 1, such as figure 1 , 3 , 5, and 8, the eccentric shaft type depressing mechanism includes a depressing reciprocating drive mechanism 4 fixed on the frame 1, and the connecting rod 5 of the depressing reciprocating drive mechanism 4 is connected to one end of the eccentric shaft 6, and the eccentric shaft 6 The other end of the slide plate 7 is movably connected; the slide plate 7 is hinged with the pressure roller adjustment plate 3, and the pressure roller adjustment plate 3 is hinged with at least two pressure rollers 2, and at least two pressure rollers 2 are along the feed of the steel bar 12 Directions are set front to back and side by side.

[0049] The depressing reciprocating drive mechanism 4 is an air cylinder, an oil cylinder, a lead screw, a screw rod or an electric pressing device driven by a motor. In this implementation, the preferred cylinder is simple in structure and convenient in maintenance.

[0050] Such as image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com