Intermediate-frequency welding control cabinet

A control cabinet, intermediate frequency technology, used in welding monitoring devices, welding power sources, welding power sources, etc., to achieve the effect of ensuring the quality of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

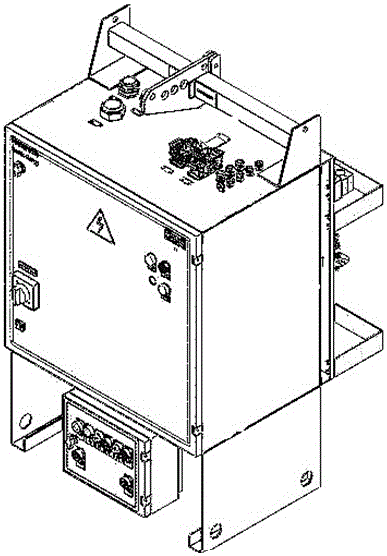

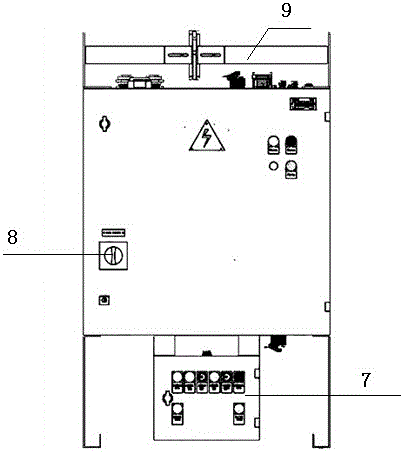

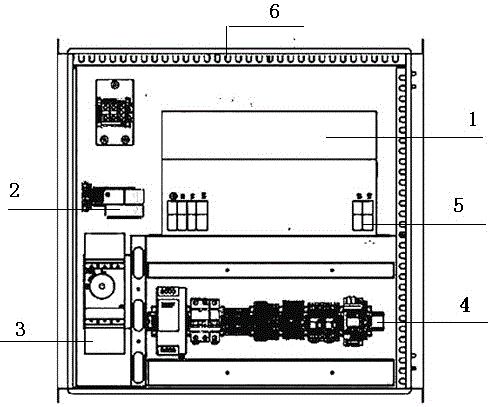

[0027] Combine below Figure 1 to Figure 7 , To further explain the present invention:

[0028] Such as figure 1 As shown, an intermediate frequency welding control cabinet is provided with a welding controller 1, a 1000HZ induction coil 2, a main power circuit breaker 3, and a 1000HZ monitor 4. The welding controller 1 is provided with a main power supply for the welding torch welding transformer The secondary side 5 of the main power supply of the welding controller is equipped with a grounding bronze plate 6 on the top of the control cabinet; a main power circuit breaker rotary handle 8 is provided on the front door of the control cabinet, and the main power circuit breaker rotary handle 8 controls the main power supply disconnection 器3; The upper end of the back of the control cabinet is equipped with a welding torch water and gas pipe and a signal cable pipe clamp 16, a protective fence 17 is provided at the lower end of the back of the control cabinet, a water circuit unit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com