Intermediate-frequency welding control system

A technology of control system and intermediate frequency, which is applied in the direction of welding monitoring device, welding power supply, welding equipment, etc., to achieve the effect of improving efficiency, saving energy and increasing the use function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

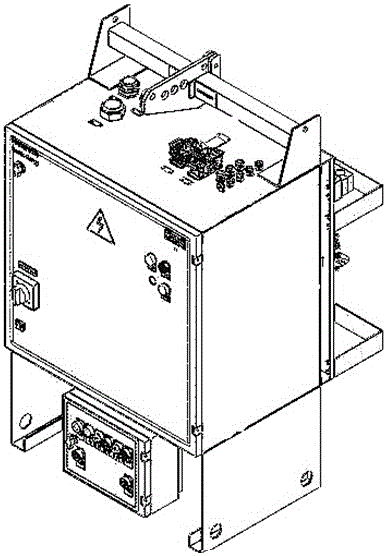

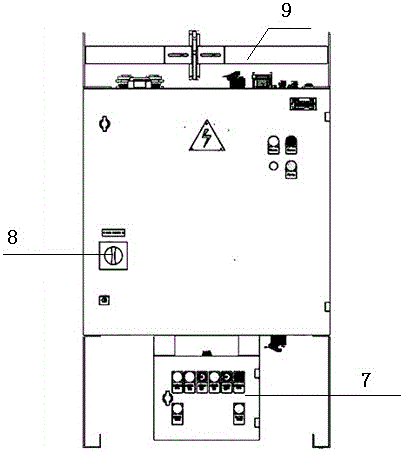

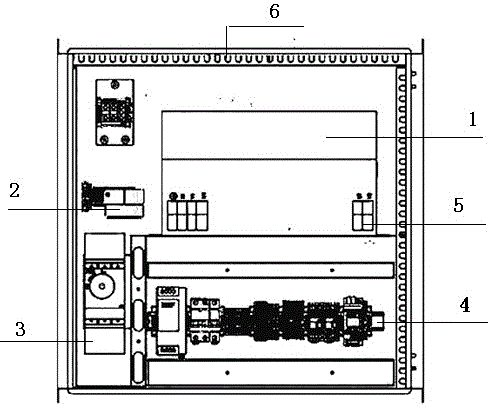

[0029] Combine below Figure 1 to Figure 6 , the present invention is further described:

[0030] Such as figure 1 As shown, an intermediate frequency welding control system, the control cabinet is equipped with a welding controller 1, a 1000HZ induction coil 2, a main power circuit breaker 3 and a 1000HZ monitor 4, and the welding controller 1 is equipped with a main power supply for the welding torch welding transformer. Welding controller main power secondary end 5, grounding copper plate 6 is provided on the top of the control cabinet; main power circuit breaker rotary handle 8 is provided on the front door of the control cabinet, and the main power circuit breaker rotary handle 8 controls the main power disconnection 3; on the upper end of the back of the control cabinet, there is a welding torch water and gas pipe and a signal cable pipe clamp 16, and on the lower end of the back of the control cabinet, there is a protective fence 17, and on the lower end of the back of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com