Welding method and device for welding with accelerated cooling

A technology of accelerated cooling and welding method, which is applied in the field of welding manufacturing, can solve the problems such as the inability to improve the structure and properties of the weld seam and the heat-affected zone, and achieve the effect of improving the embrittlement and softening problems and improving the metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

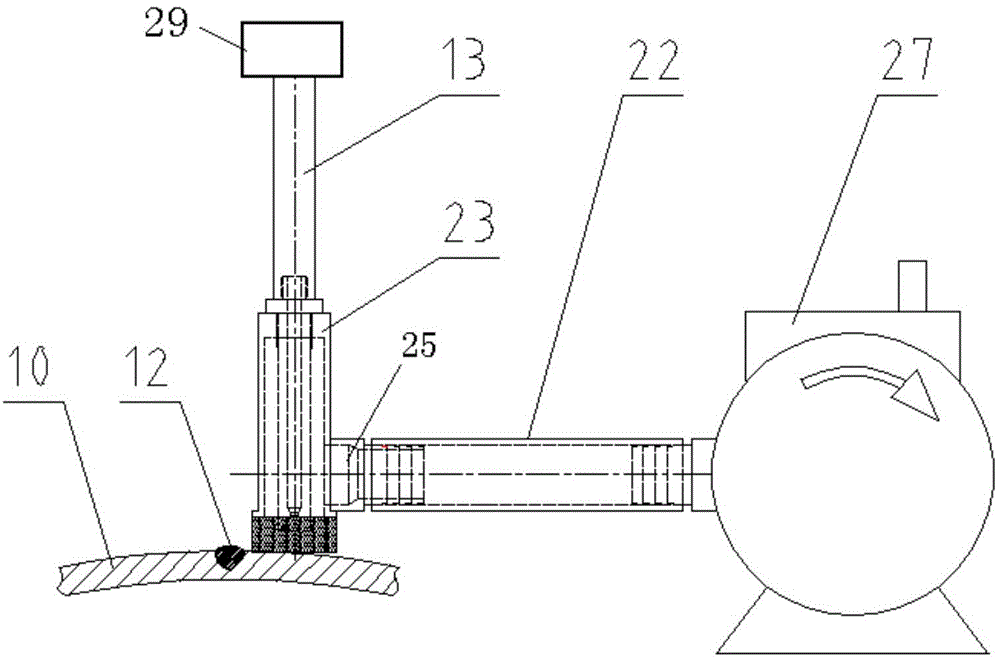

[0049] see figure 2 , the embodiment of the present invention provides a welding method of accelerated cooling with welding, the method is to accelerate the cooling of the weld seam and the heat-affected zone or the local area of the base metal during the welding process, so as to improve the metallographic structure and mechanical properties.

[0050] The present invention improves the surface heat transfer coefficient of the steel plate through the above method, enhances the cooling effect, and accelerates the cooling of the weld seam and the heat-affected zone in a high-temperature state with welding, thus controlling and changing the inherent heat cycle in the welding process The process speeds up the cooling speed of the weld seam and the heat-affected zone, and superimposes the heat source of large heat input and the cold source generated by the accelerated cooling device with welding, resulting in a higher cooling speed than low-line energy welding. It has proved th...

Embodiment 2

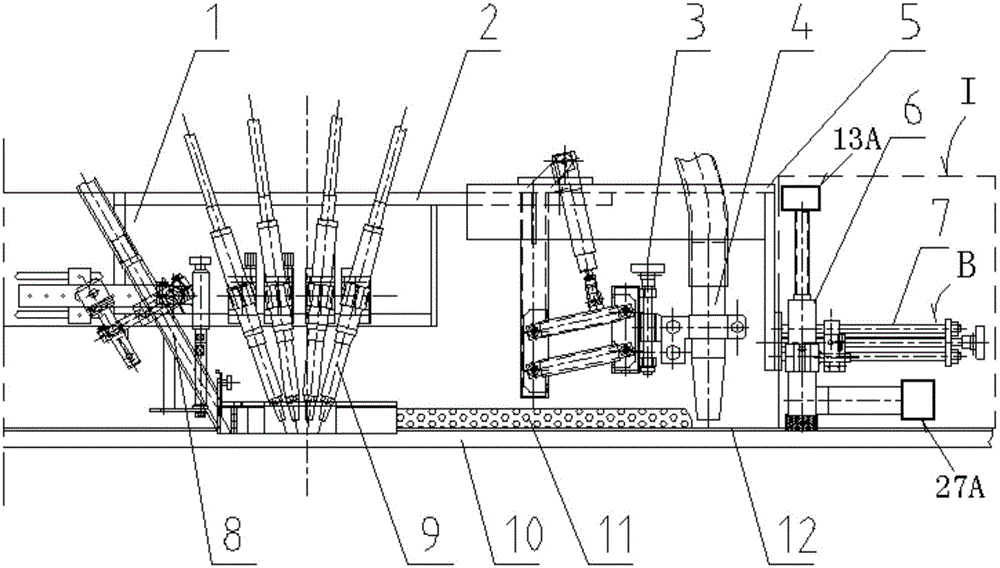

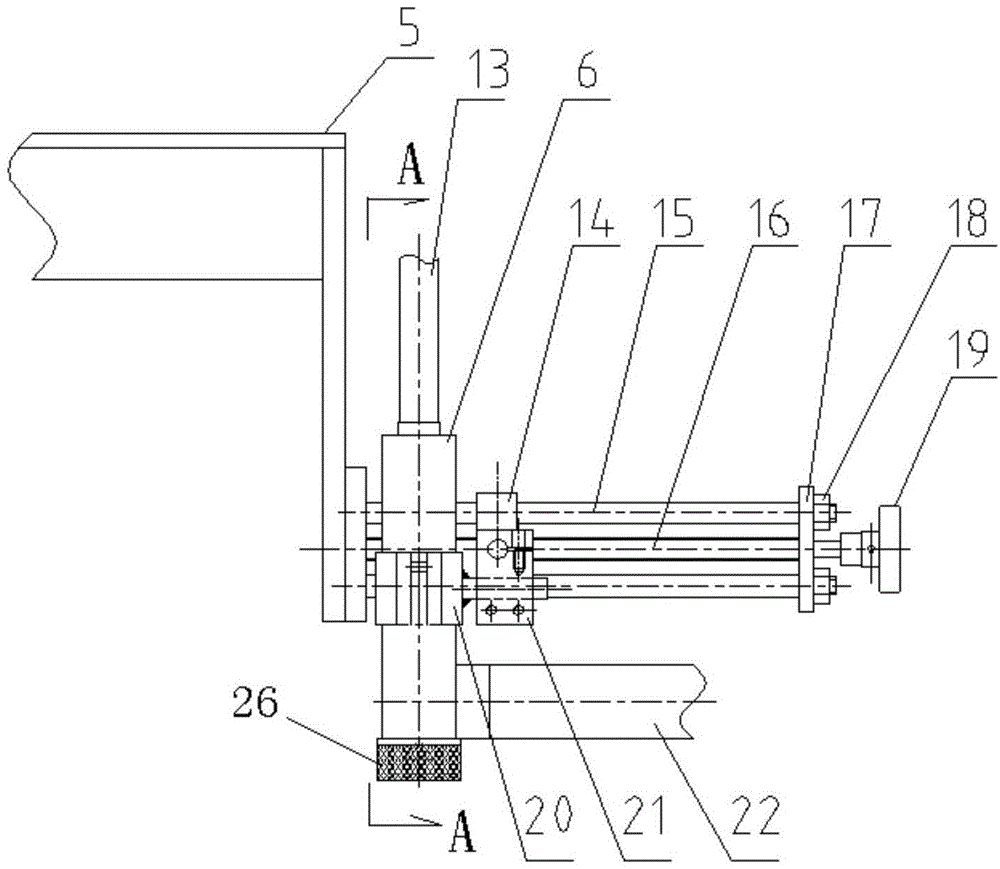

[0057] Such as figure 1 shown, see also figure 2 , this embodiment takes figure 1 To illustrate mainly, the embodiment of the present invention provides a device 1 for accelerated cooling with welding, which is installed on the welding machine head 1, and the device is installed on the welding machine head 1 through a connecting piece 5, the described The device 1 moves synchronously with the welder head 1, and the device 1 includes a driving connection part B, a clamping adjustment part 7, a spray head 6, a medium conveying part 13A and an adsorption part 27A,

[0058] The driving connection part B is connected to the welder head 1, and the driving connection part B is used to drive the spray head 6 to move linearly,

[0059] The clamping adjustment part 7 is connected with the driving connection part B and moves relative to the driving connection part B. The clamping adjustment part 7 is used to clamp the spray head 6 and drive the spray head 6 to move horizontally and ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com