Double-spring clamp auxiliary supporting device

An auxiliary support and double spring technology, applied in the field of machining, can solve the problems of the gap between the support column and the workpiece, the rigidity is not ideal, the bearing capacity is small, and the effect of ensuring reliability, small space occupation and reasonable structure can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

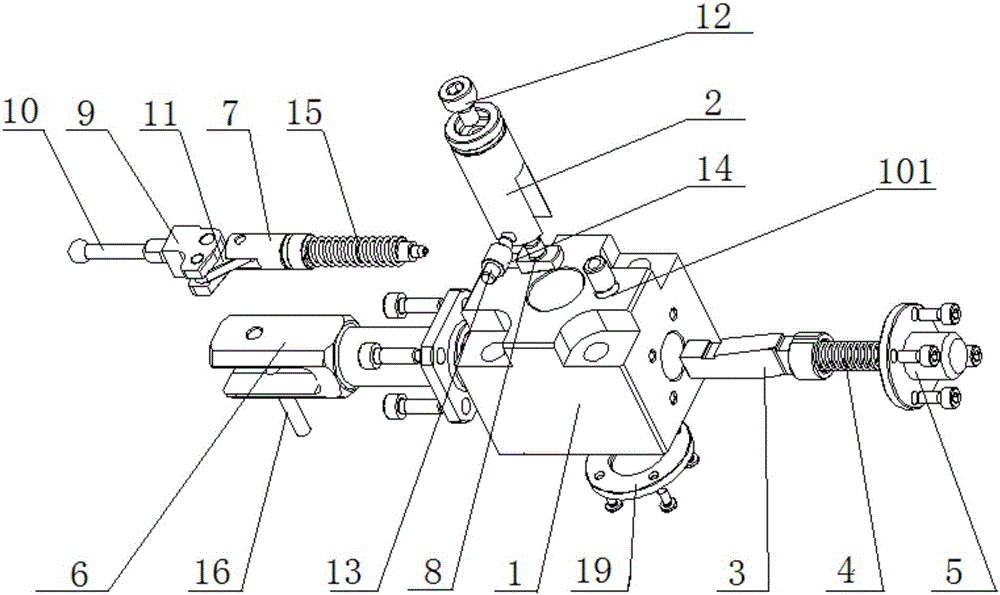

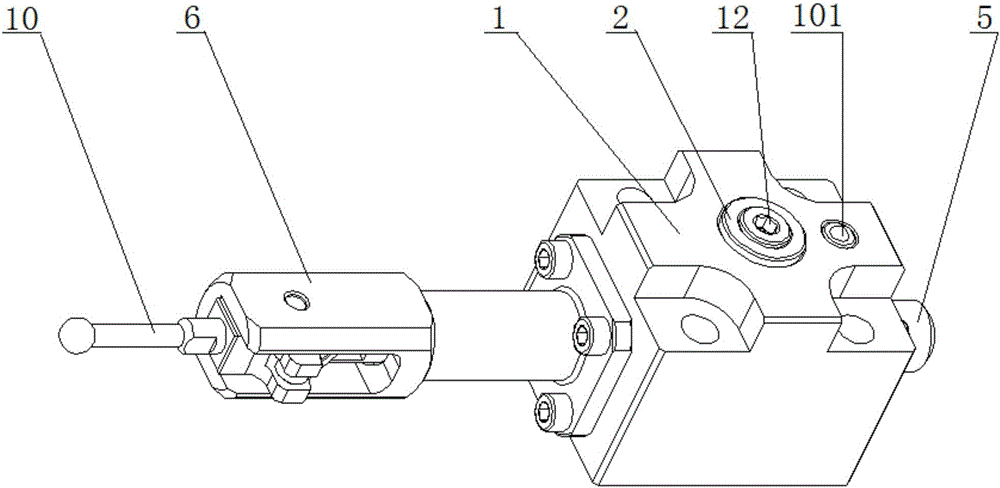

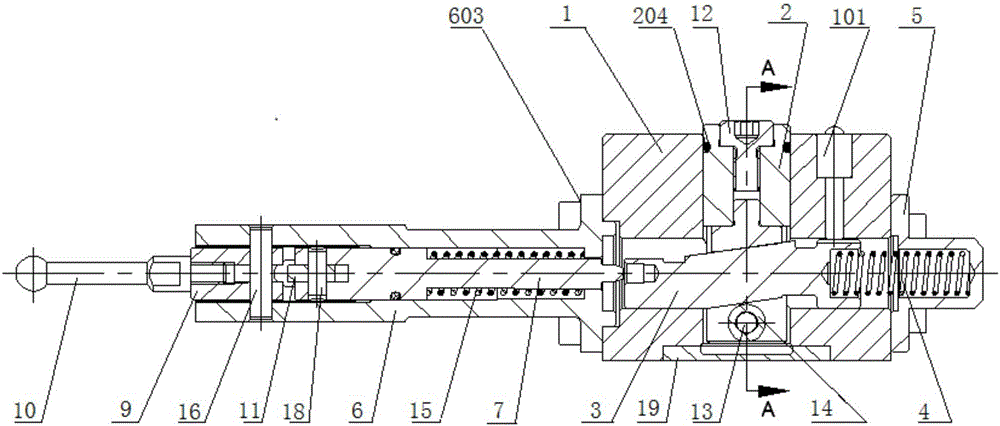

[0039] The specific embodiment of the present invention is like this: with reference to Figure 1-Figure 20 As shown, a double spring clamp auxiliary support device includes a hollow support seat 1, and a support column 2 for supporting the workpiece is installed in the support seat 1, which can slide up and down. The first wedge 3 of the column 2, the first wedge 3 has an upper wedge surface and a lower wedge surface parallel to each other, and the support column 2 is provided with a lifting mechanism that slides relative to the upper wedge surface of the first wedge 3 and rises. A descending mechanism that slides relative to the lower wedge surface of the first wedge 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com