Passive variable-rigidity longitudinal thrust rod and air suspension for installing longitudinal thrust rod

A longitudinal thrust rod, passive technology, which is applied to the cantilever, suspension, elastic suspension and other directions mounted on the pivot, can solve the problems of vehicle ride comfort, fall off, and the rigidity of the longitudinal thrust rod is not variable, so as to achieve a comfortable ride. The effect of improved performance and smoothness, convenient and practical installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

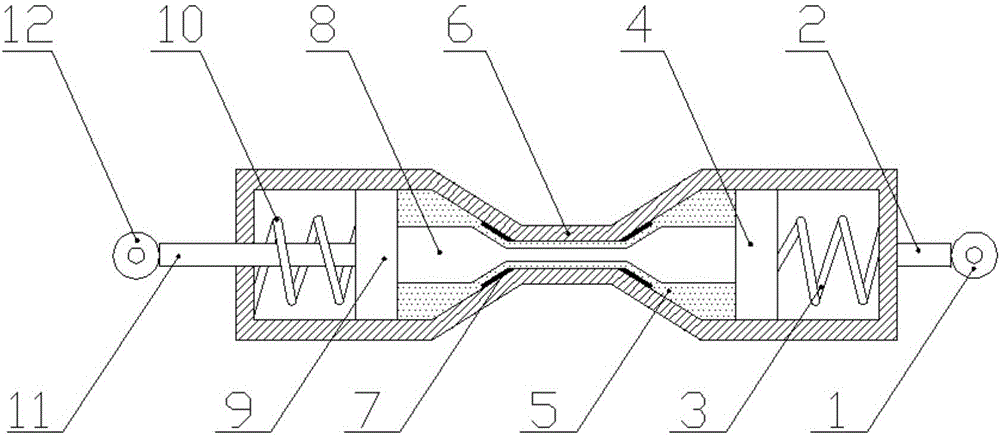

[0032] figure 1 Shown is an embodiment of the passive variable stiffness longitudinal thrust rod of the present invention. The passive variable stiffness longitudinal thrust rod includes a front suspension ring 1, a support rod 2, a front spring 3, a front piston 4, and oil 5 , Working chamber 6, rubber sleeve 7, connecting rod 8, rear piston 9, rear spring 10, piston rod 11 and rear suspension ring 12.

[0033] The two ends of described working chamber 6 are respectively cylindrical front working chamber 601 and rear working chamber 602, and the center is a cylindrical middle pipe 603 whose diameter is smaller than front working chamber 601 and rear working chamber 602. The working chamber 602 communicates with both ends of the middle pipe 603 through the tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com