Vehicle torsional vibration control method, device and system

A technology of torsional vibration and control method, which is applied in the control of drive, vehicle components, electric vehicles, etc., can solve problems affecting the driving comfort of the whole vehicle and passenger comfort, and achieves improved driving smoothness, good torsional vibration, and reduced shaft speed. The effect of speed fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

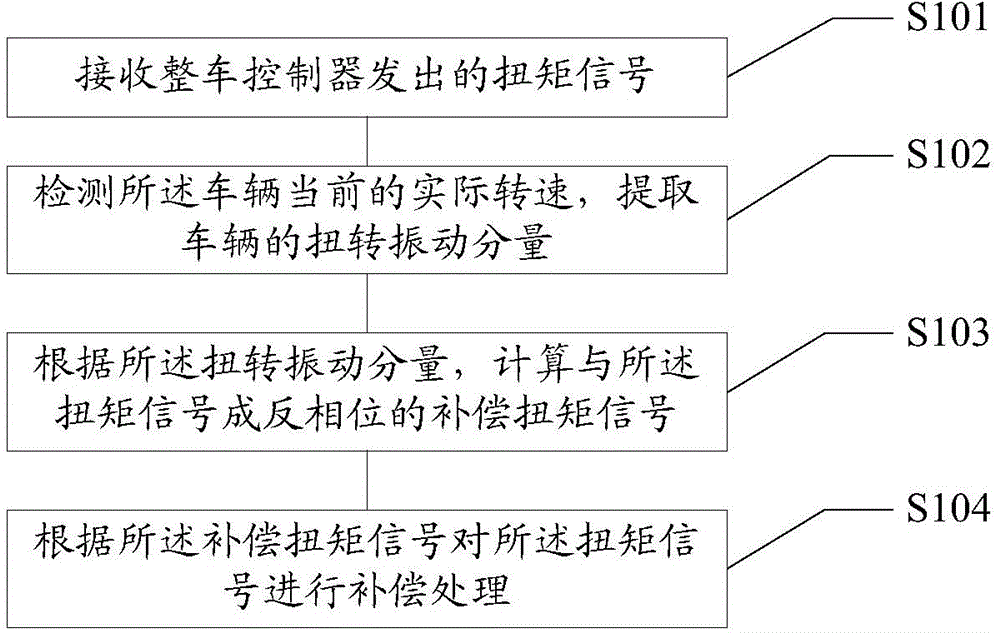

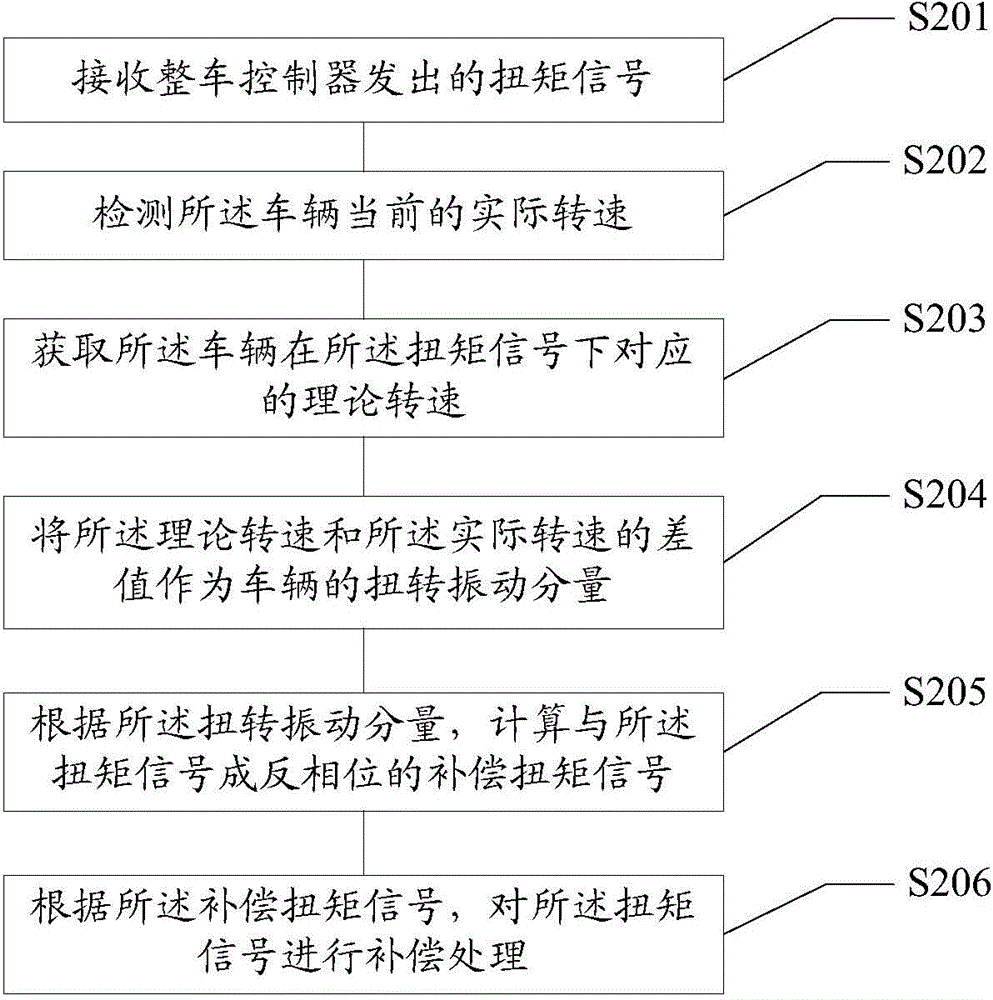

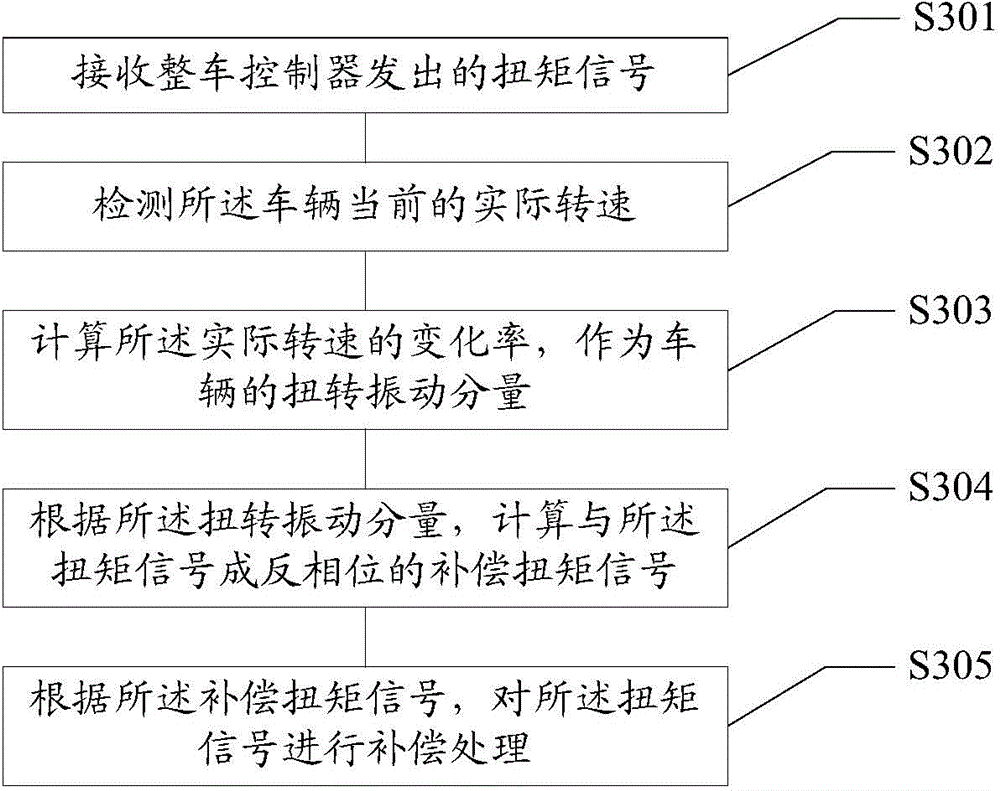

Method used

Image

Examples

Embodiment Construction

[0030] When the torque load of the vehicle drive motor acts on the transmission system, it will cause the torsional vibration of the shaft system of the transmission system. For example, during the actual operation of an electric vehicle, when the vehicle starts or the torque has a large step response, the transmission system will generate torsional vibration at a fixed frequency, which is manifested by periodic fluctuations in the shafting speed of the transmission system, far exceeding the wheel speed Therefore, it brings a feeling of front and rear jitter to the whole vehicle, which affects the driving comfort of the whole vehicle and the comfort of passengers.

[0031] In the prior art, for the torsional vibration of the electric vehicle system, the main method adopted is to reduce the loading slope of the motor torque. However, a too low loading slope will reduce the torsional vibration of the vehicle, so it cannot effectively balance the needs of vehicle torque loading s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com