Mechanical structure and use method of compact hand-held tape winding machine

A technology of mechanical structure and tape winding machine, which is applied to the parts of strapping machinery, strapping objects, packaging/bundling objects, etc. It can solve the problems of no large-scale promotion of equipment, lack of adaptive feeding mechanism, etc., and achieve the setting speed Simple and reliable, compact size, and the effect of reducing space waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

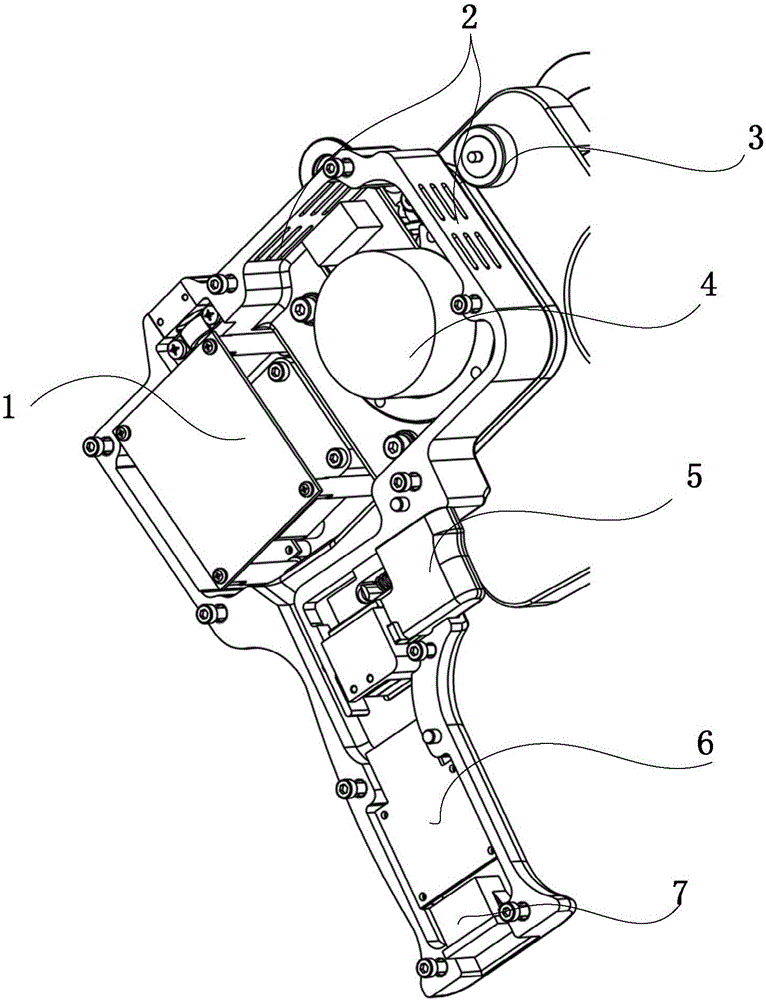

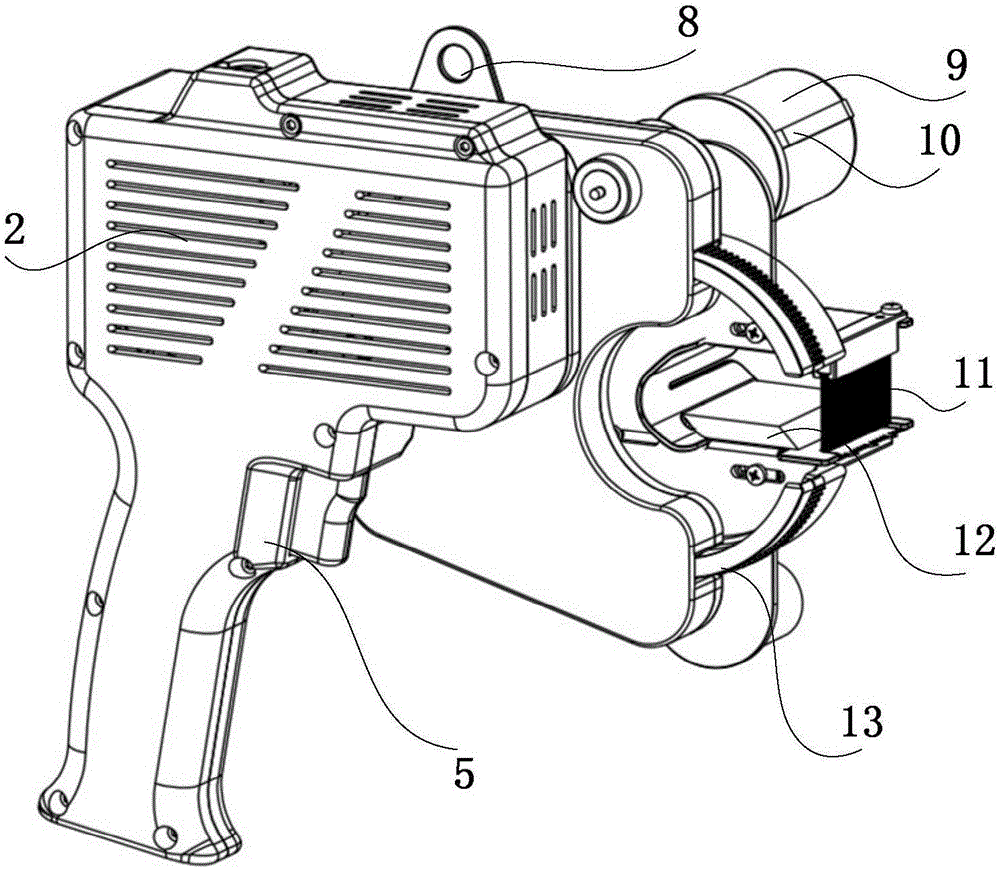

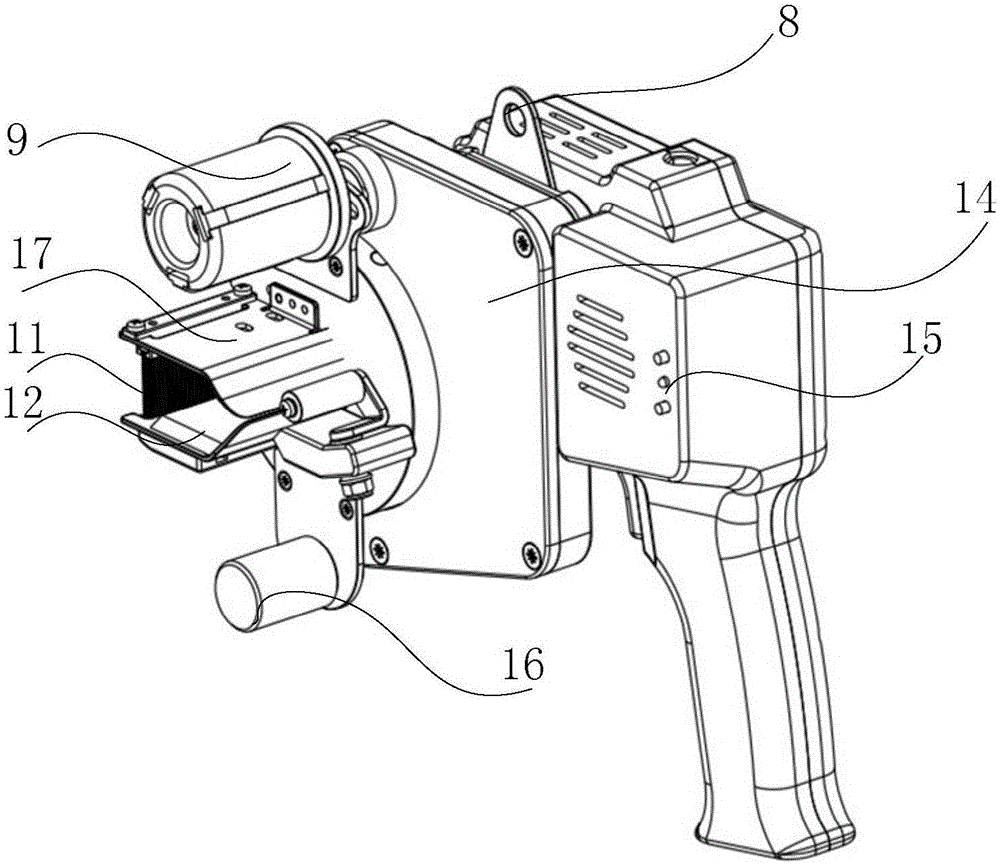

[0039] Such as Figure 1~3 As shown in the figure, the mechanical structure of a compact hand-held tape winding machine includes a chassis mechanism, a handle mechanism, a button adjustment mechanism, a feeding mechanism, a heat dissipation mechanism and a gap elastic opening mechanism.

[0040] The chassis mechanism includes a chassis shell, in which a motor 4, a fan, a key adjustment module and a controller 1 are arranged; the motor 4 is arranged at the front end of the chassis shell, and its output shaft is connected with the transmission mechanism in the gearbox 14; the key The adjustment module and the fan 2 are arranged at the rear end of the chassis shell, and the front of the fan is provided with a controller; the top position corresponding to the rear end of the chassis shell is provided with a power inlet; There is a lifting ring 8, and the position of the longitudinal bisector of the lifting ring is set on the center of gravity of the entire machine. The lifting rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com