a packing machine

A baler and main body technology, applied in the field of balers, can solve the problems of cumbersome operation process, large space occupation, unrealistic, etc., and achieve the effect of avoiding the cooperation of multiple people, avoiding the deformation of the packing belt, and reliable transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

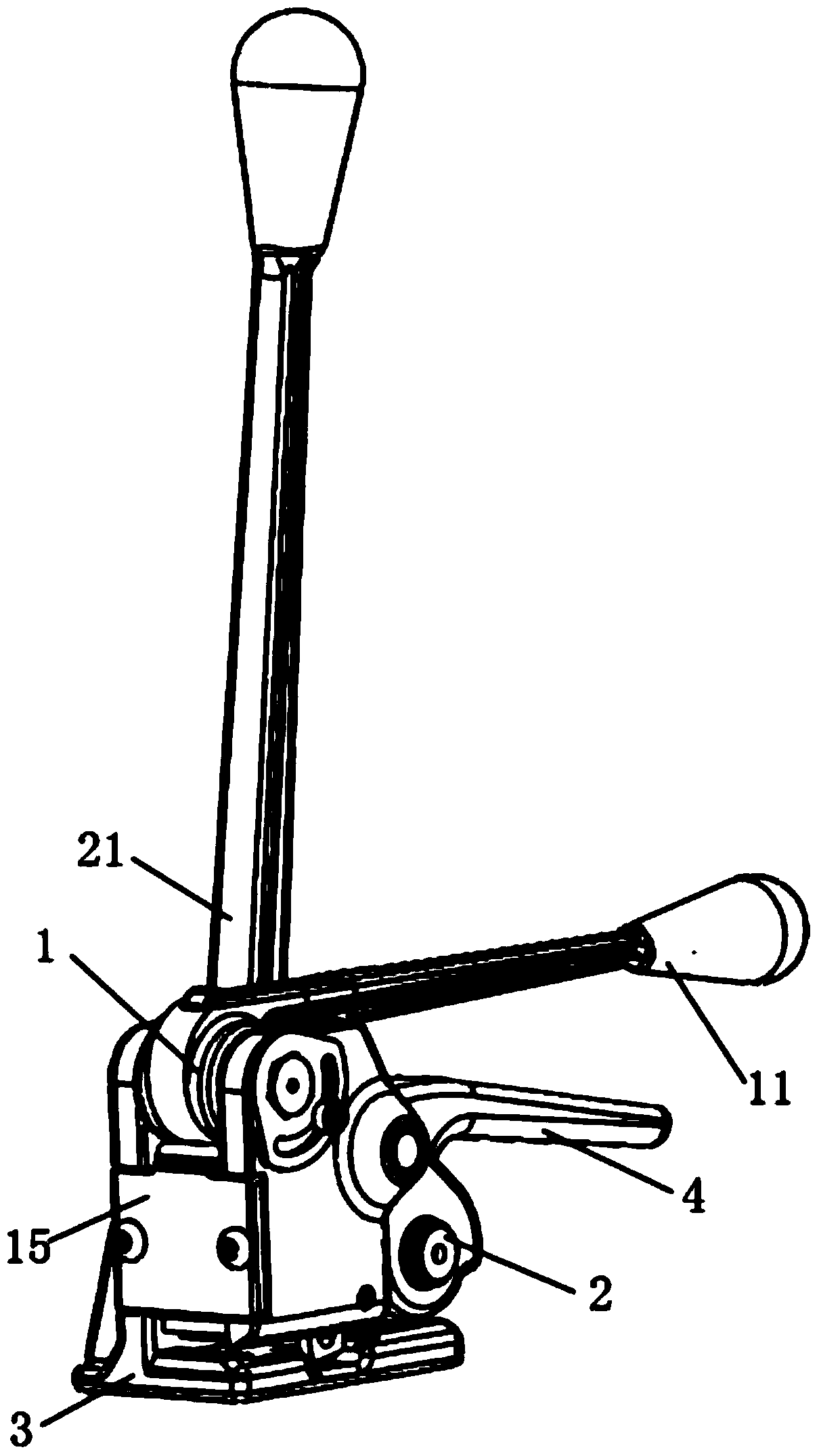

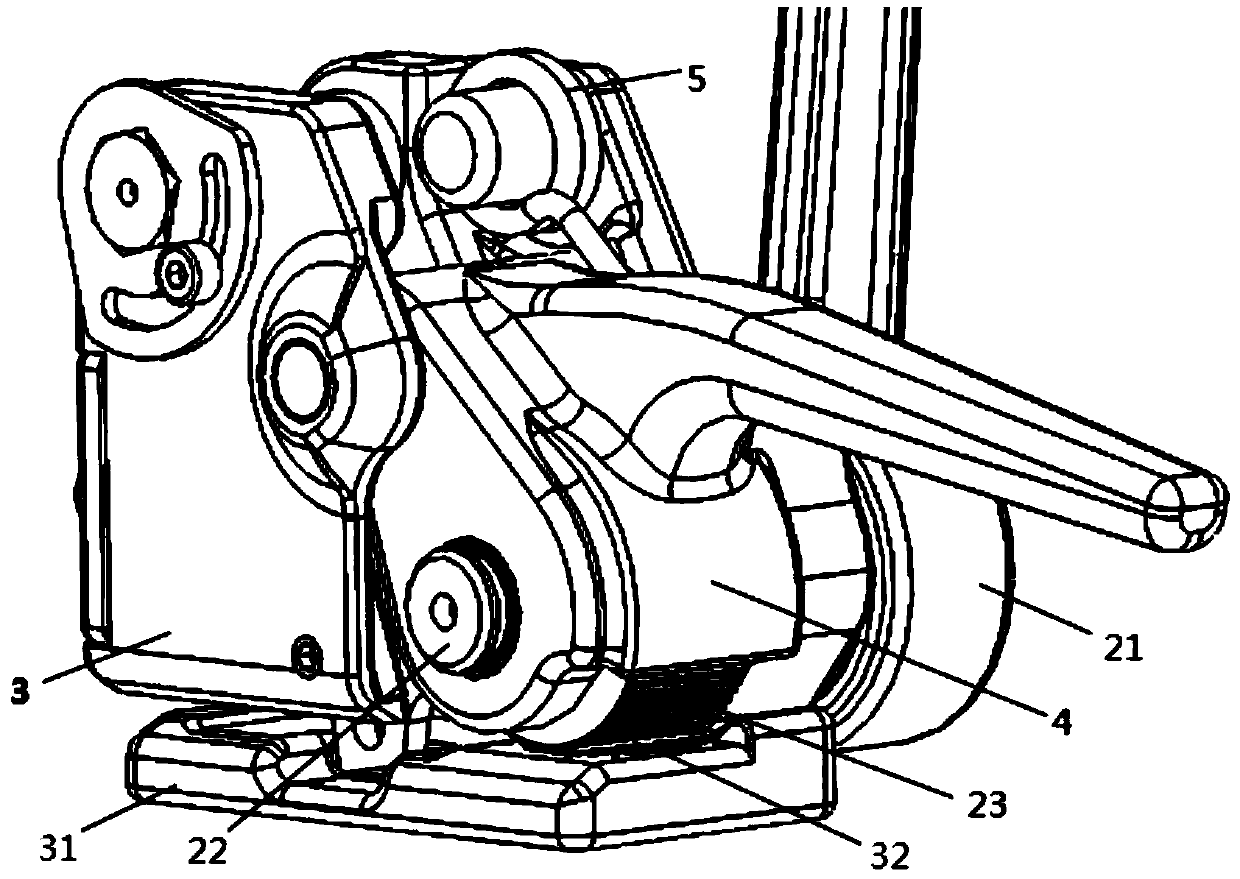

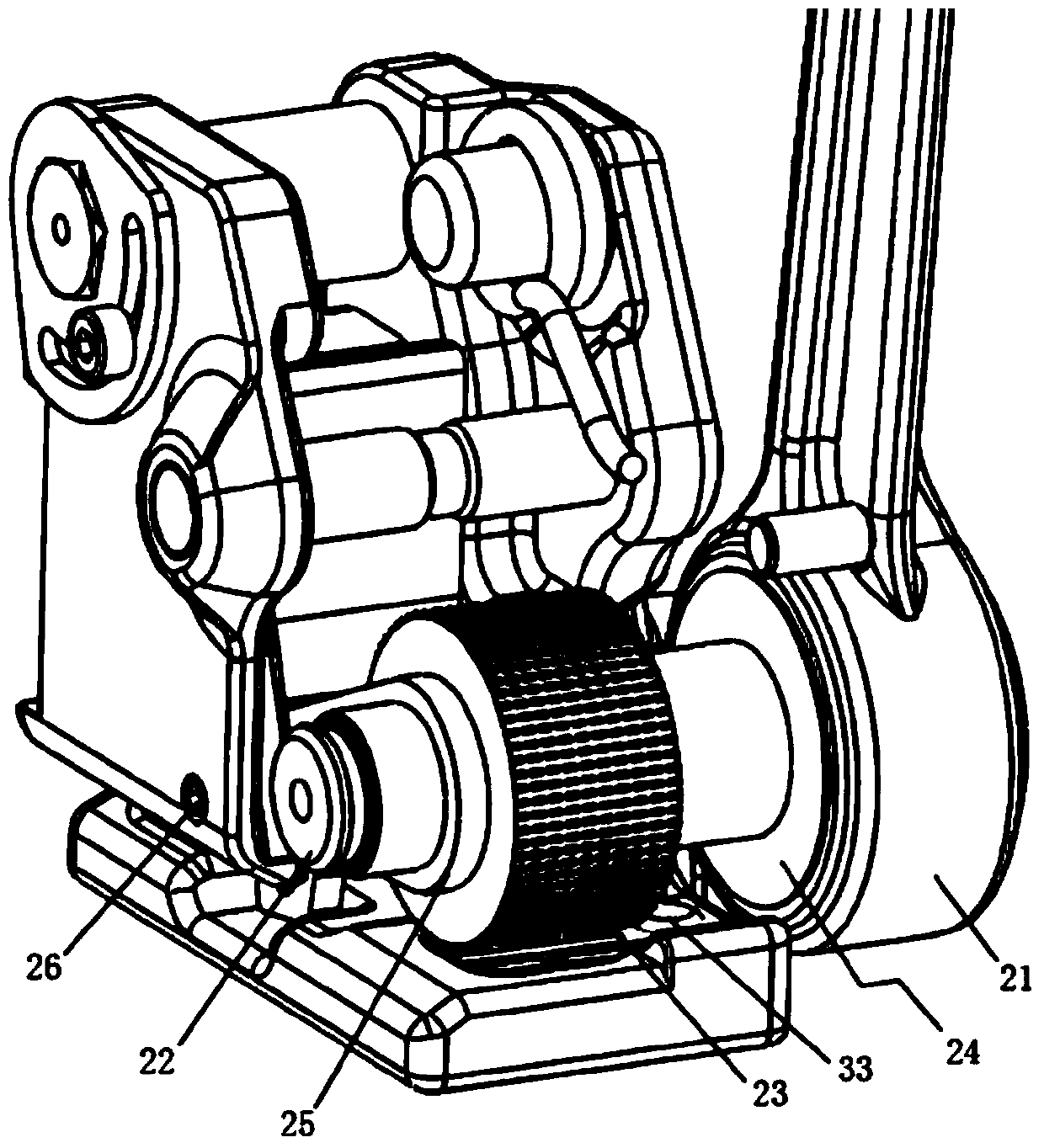

[0032] This embodiment provides, such as Figure 1-Figure 5 A baler shown includes a main body 3 with an installation space, a cutter device 1 arranged at the front end of the installation space, and a tightening device 2 arranged at the rear end of the installation space; the tightening device 2 includes The shaft seat and the tightening shaft partially accommodated in the shaft seat, the tightening wheel 23 sleeved on the tightening shaft 22, the tightening handle 1 that drives the tightening shaft 22 to rotate, and the main body 3 Corresponding to the pressure plate hanger 32 set on the tightening wheel 23, an anti-retraction structure 24 is arranged between the tightening handle 21 and the tightening shaft 22. When the tightening handle 21 rotates forward, the tightening handle 21 drives the tightening shaft 22 to rotate in conjunction with the anti-retraction structure 24; when the tightening handle 21 rotates in the opposite direction, the anti-retraction structure 24 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com